Ultra-frost-resistant cement profile and preparation method thereof

A technology of frost resistance and cement, applied in the field of super frost resistance cement profiles and its preparation, can solve the problems of increasing the number of harmless holes and reducing the water content of concrete, so as to reduce porosity, improve frost resistance and reduce the quantity Effect

Inactive Publication Date: 2017-05-24

YANCHENG INST OF TECH

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, none of the existing reports can significantly increase the number of harmless pores and reduce the water content of concrete. Therefore, it is impossible to fundamentally find a way to improve the frost resistance of concrete.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0018] The present invention will be further described in detail below in combination with specific embodiments.

[0019] The components used in Examples 1-5 are shown in Table 1 (mass percentage), and the steel slag and slag used in the examples are all obtained from Baosteel Group Corporation.

[0020] Table 1

[0021]

[0022]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

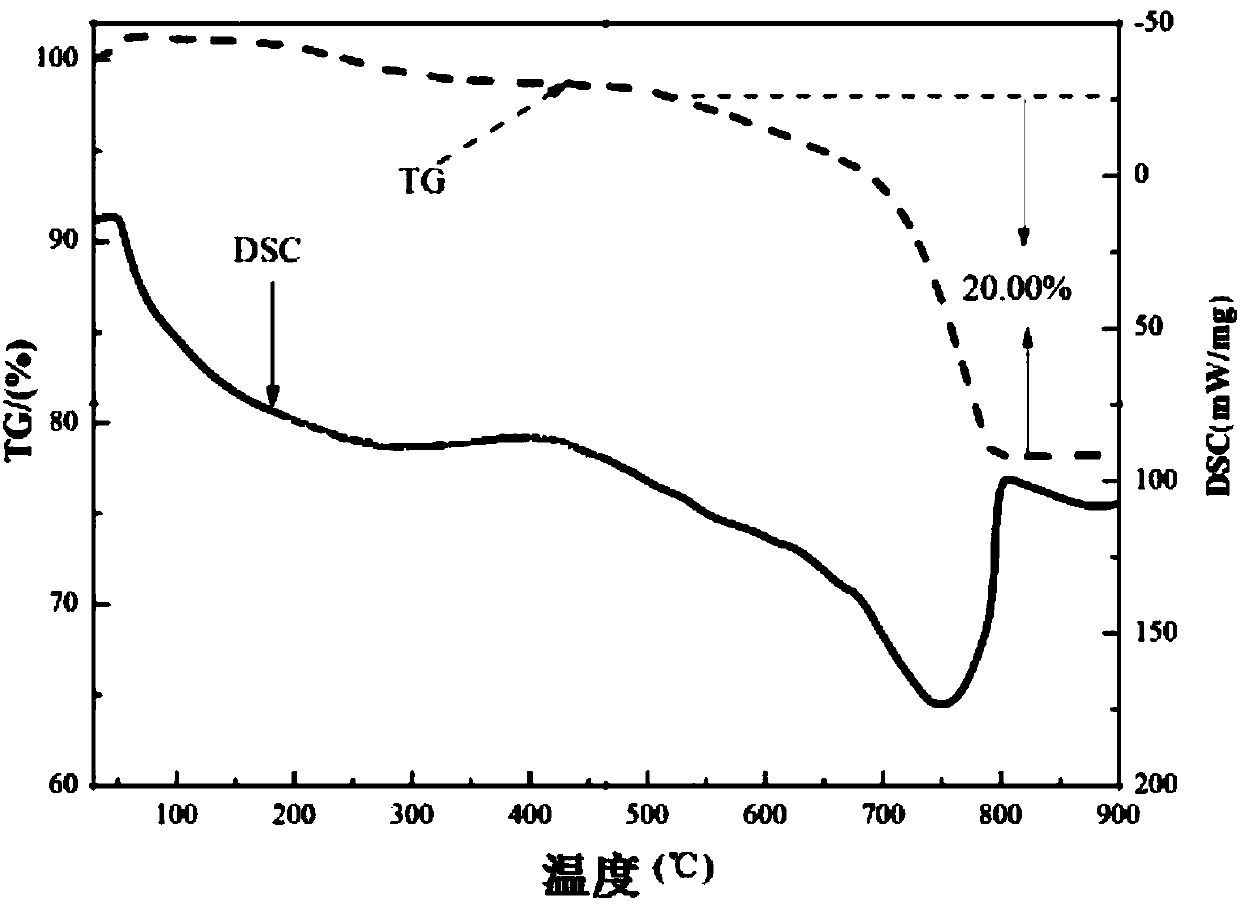

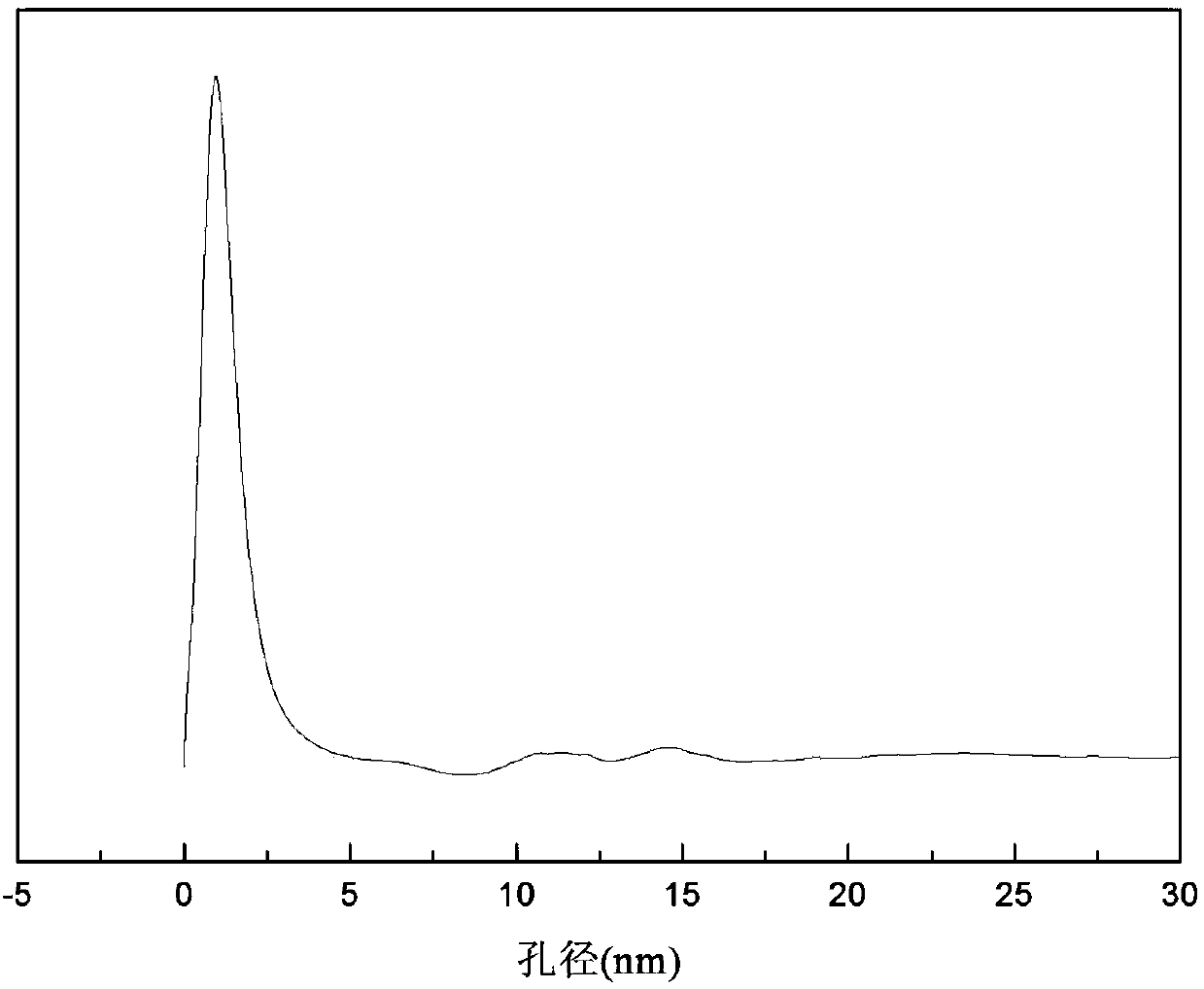

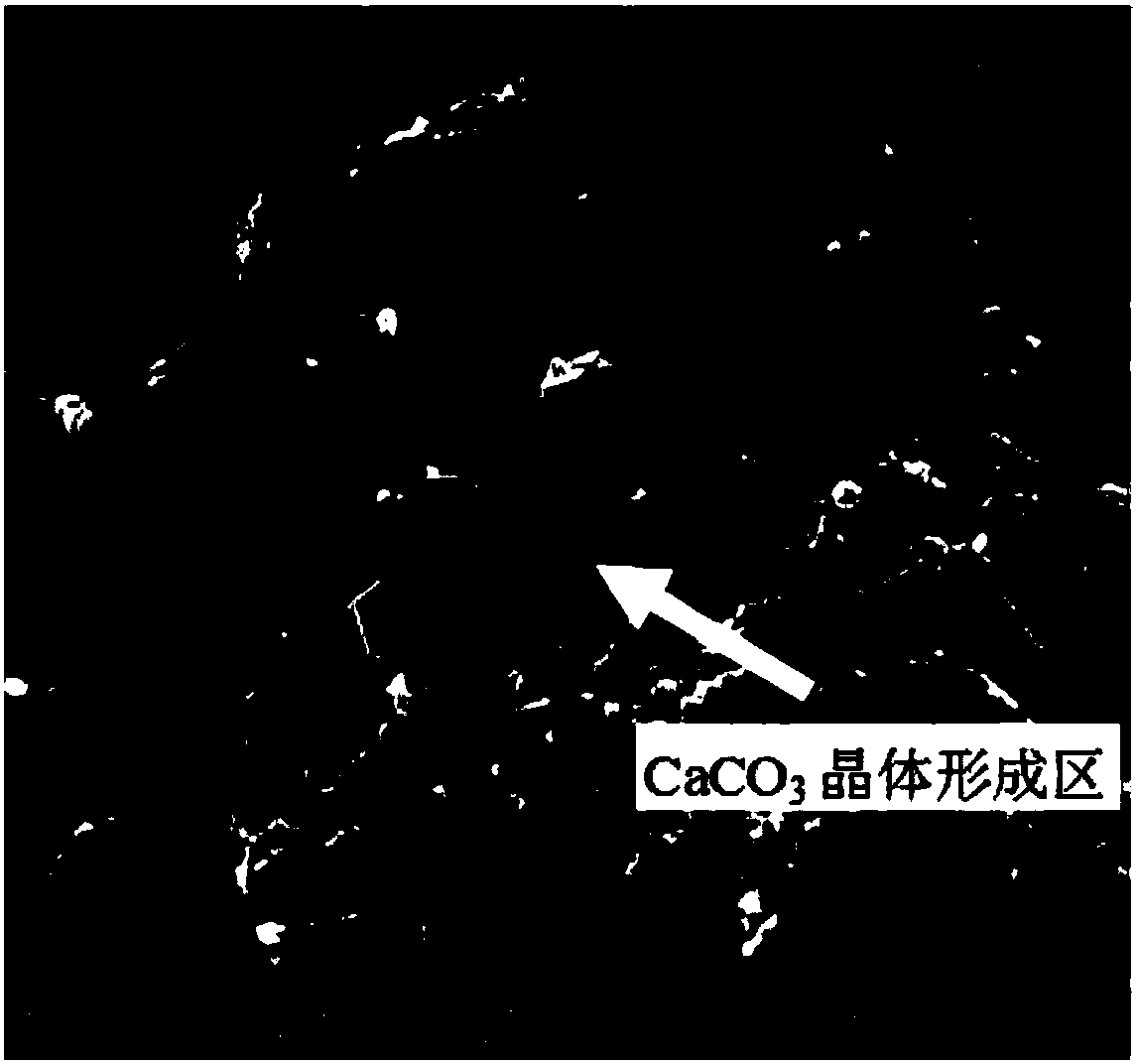

The invention relates to an ultra-frost-resistant cement profile and a preparation method thereof. The ultra-frost-resistant cement profile comprises the following components in percentage by mass: 50-100% of C3S2 cement, 0-40% of steel residues and 0-25% of ore slag. The preparation method comprises the following steps: (1) grinding and screening the C3S2 cement or a mixture of the C3S2 cement, the steel residues and the ore slag, controlling a water-ash ratio to be 0.19-0.35, and performing vibration molding so as to obtain a blank; (2) putting the blank into a reaction kettle with a CO2 gas, and performing a heating reaction, thereby obtaining the ultra-frost-resistant cement profile. The ultra-frost-resistant cement profile has calcium carbonate crystal of CO2 and calcium-containing minerals in blank pores, and along with increase of the reaction time, the pores are fully filled with the crystal, so that the porosity can be degraded, the number of harmless pores can be reduced, and the frost resistance of the cement can be improved.

Description

technical field [0001] The invention belongs to the field of building materials, in particular to a super frost-resistant cement profile and a preparation method thereof. Background technique [0002] Freeze-thaw damage is one of the main reasons for the damage of concrete, especially in low temperature and cold regions, due to the freezing and expansion of the solution in the pores, micro-crack damage occurs inside the concrete, and such damage gradually disappears under the action of multiple freeze-thaw cycles Accumulative expansion eventually leads to loosening and cracking inside the concrete. The essential factor of freeze-thaw damage is that the concrete contains pores and aqueous solution. According to the influence of different pore sizes on the performance of concrete, Wu Zhongwei, a famous scientist in my country, divides the pores in concrete into harmless pore levels. less harmful hole level Harmful hole level and Hazardous Hole and proposed to increase...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B28/04C04B40/02C04B111/20

CPCC04B28/04C04B40/0231C04B2111/29C04B18/142C04B18/141

Inventor 侯贵华张宏伟陈佳男许宁张勤芳曹月斌

Owner YANCHENG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com