Method for separating copper-soldering tin mixture and device for achieving method

A mixture and solder technology, applied in the field of a method and a device for realizing the method, can solve the problems of inability to realize separation, inability to separate copper, inability to separate solder and copper, etc., and achieve resource recovery and easy scale. Achieving and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

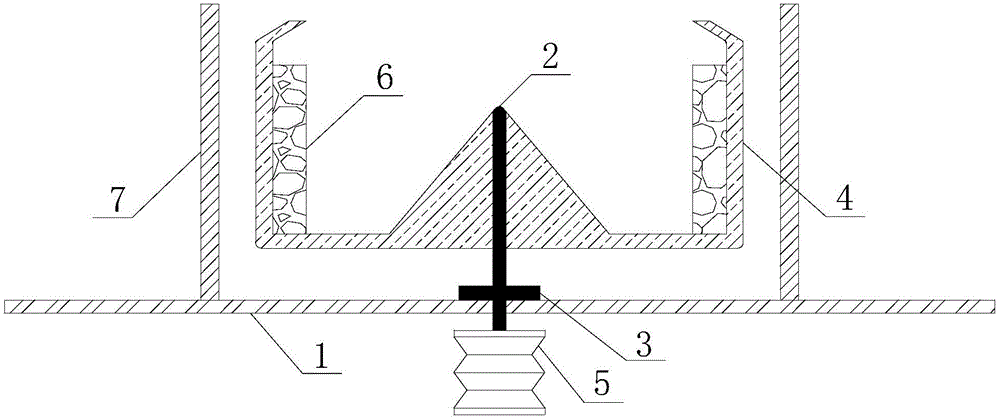

[0032] see figure 1 As shown: a device for separating copper and solder mixture through external heating provided in this embodiment includes a rotating drum 4 and an external heating ring 7 located outside the rotating drum 4, the rotating drum 4 is fixed on the rotating shaft 2, and the rotating shaft 2 passes through the bearing 3 Connected to base 1. A belt pulley 5 is installed on the lower end of the rotating shaft 2, and the belt pulley 5 is connected with the power unit (not shown). When the belt pulley 5 rotates under the drive of the power device, the drum 4 also rotates synchronously, and the copper and solder mixture 6 inside the drum 4 rotates at the same time. Under the heating action of the outer heating ring 7, the solder in it melts into liquid, Then it is thrown out from the drum 4 under the action of centrifugal force, so as to realize the separation from copper.

Embodiment 2

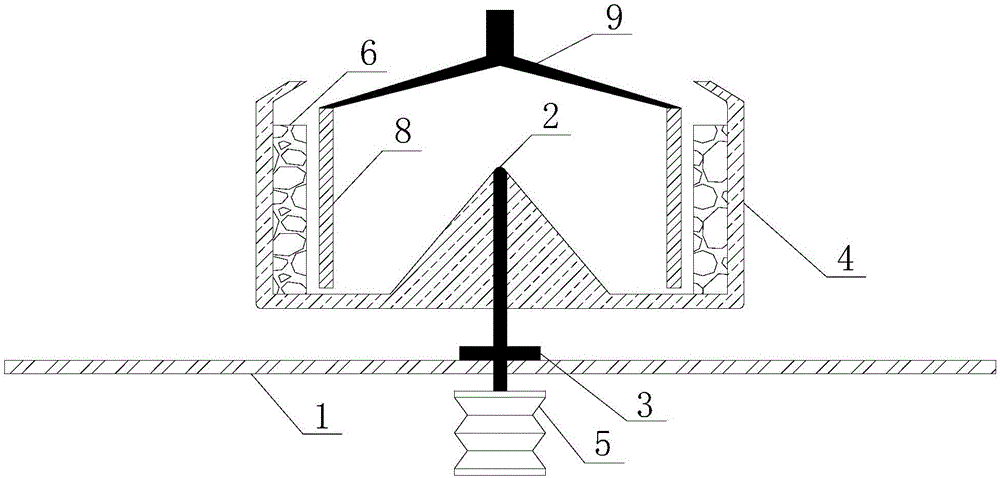

[0034] see figure 2 As shown: a device for separating copper and solder mixture through internal heating provided in this embodiment includes a drum 4 and an inner heating ring 8 located in the drum 4, and the inner heating ring 8 is suspended on the drum by an inner heating ring bracket 9 4, the copper and solder mixture 6 is heated by the inner heating ring 8, and the solder in it melts into a liquid, and then is thrown out from the drum 4 under the action of centrifugal force, thereby realizing the separation from the copper.

Embodiment 3

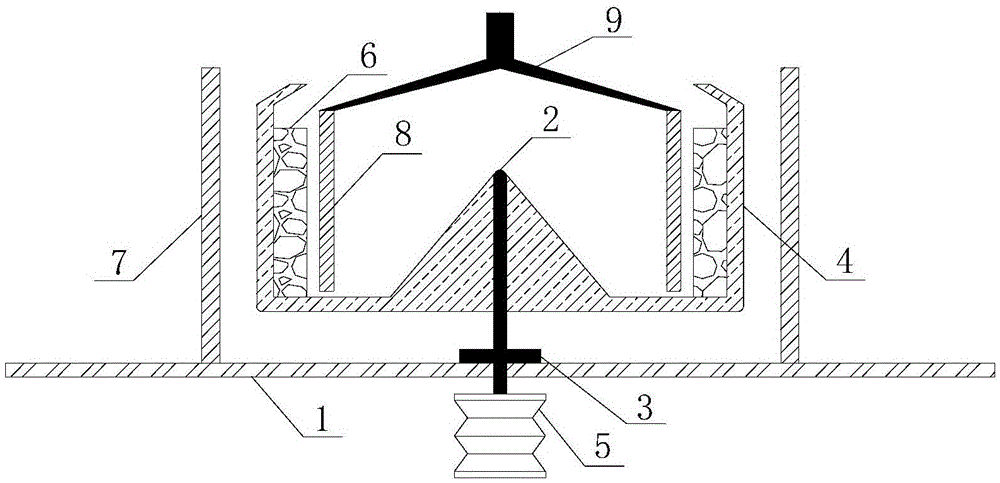

[0036] see image 3 As shown: a device for separating copper and solder mixture through internal and external heating provided in this embodiment includes a drum 4, an outer heating ring 7 located outside the drum 4 and an inner heating ring 8 located inside the drum 4, the copper Under the simultaneous heating of the outer heating ring 7 and the inner heating ring 8, the solder in the mixture 6 melts into a liquid, and then is thrown out from the drum 4 under the action of centrifugal force, thereby realizing the separation from the copper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com