Anti-seismic node of reinforced concrete column beam

A reinforced concrete, column-beam technology, applied in the direction of earthquake resistance, building types, buildings, etc., can solve the problems of overall structural failure, safety hazards, failure to achieve the design goals of strong columns and weak beams, etc., to protect the node structure and prevent structural failure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

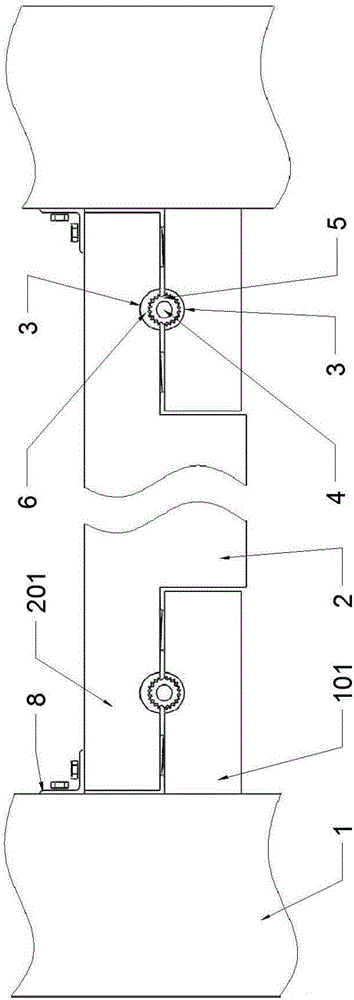

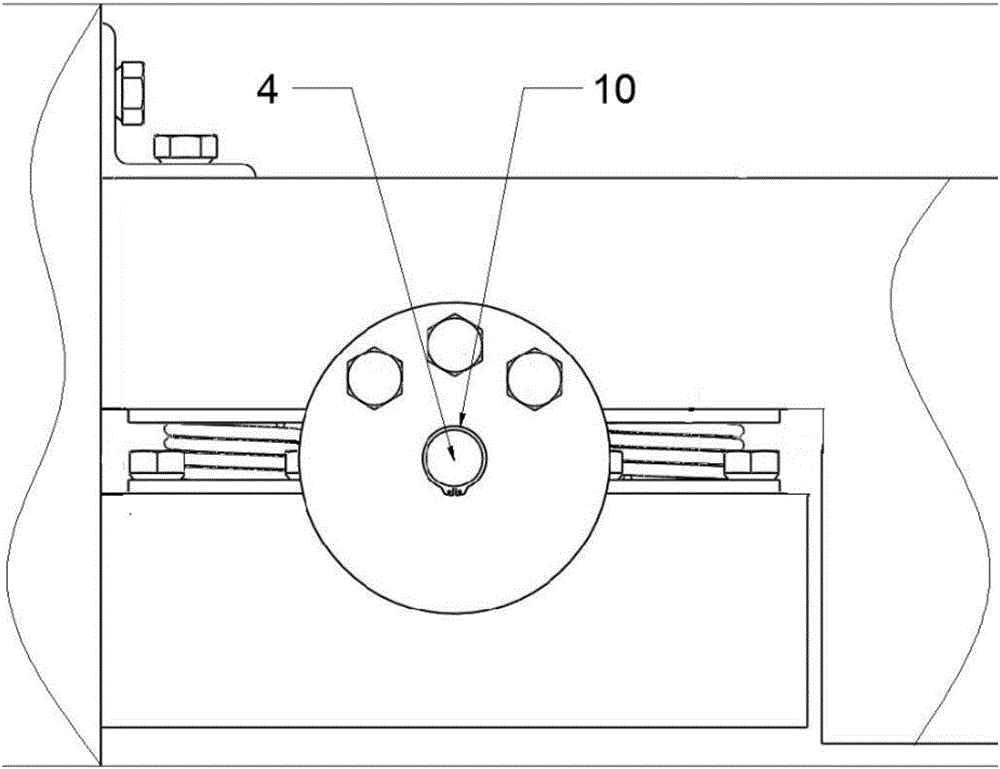

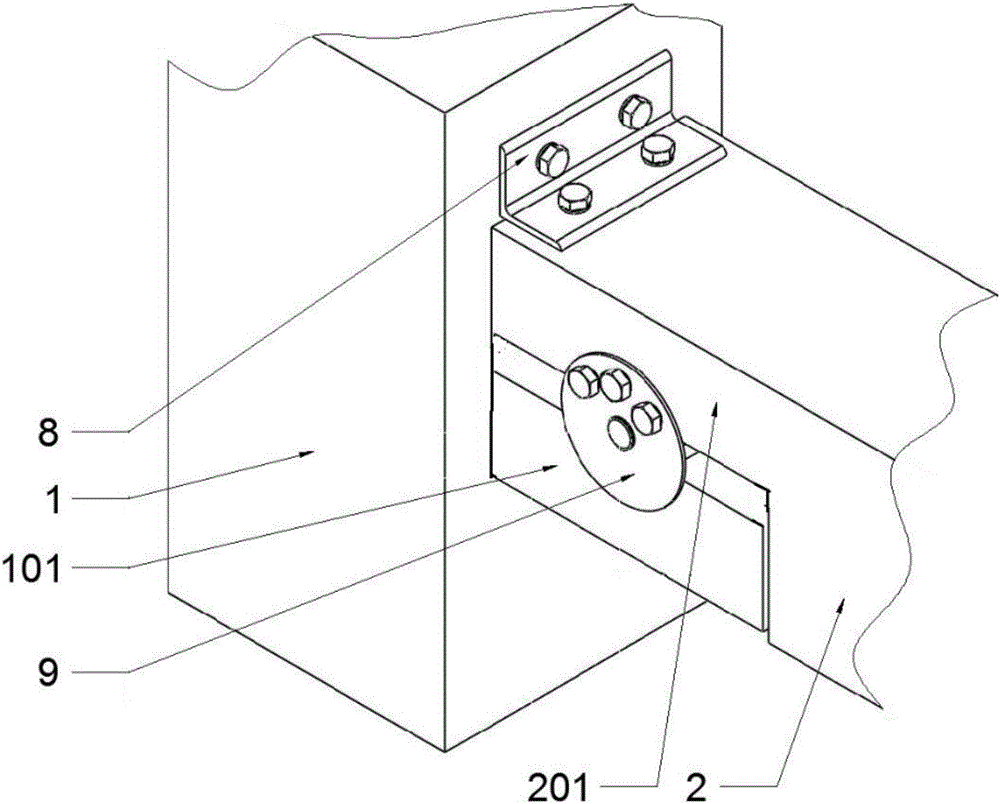

[0039] Such as Figure 1 to Figure 13 As shown, a reinforced concrete column-beam seismic joint according to the present invention includes a frame column 1, the frame column 1 extends outward to form a corbel 101, and the two ends of the frame beam 2 between the frame columns 1 extend outward A protruding part 201 matching with the corbel 101 is formed, the upper surface of the corbel 101 and the lower surface of the protruding part 201 are provided with mutually matching grooves 3, and the groove 3 is pre-embedded with a set The internal gear 5 fixed on the rotating shaft 4 matches the external gear 6 , and the rotating shaft 4 is fixed between the grooves 3 through the fixing ring 7 pre-embedded in the corbel 101 . During an earthquake, the friction loss between the internal gear 5 and the external gear 6 causes the frame beam 2 and the frame column 1 to rotate relative to the rotating shaft 4 to form a plastic hinge structure to protect the structure and prevent structural...

Embodiment 2

[0050] Such as Figure 14 to Figure 17 As shown, in this embodiment, preferably, the cross-sectional shape of the teeth of the internal gear 5 and the external gear 6 is triangular, so that a sufficiently large frictional resistance is generated between the internal gear 5 and the external gear 6 .

[0051]Preferably in this embodiment, a spring 11 is installed between the corbel 101 and the protrusion 201, the spring 11 is pre-embedded in the corbel 101, and the springs 11 located on both sides of the rotating shaft 4 can limit the rotation range of the frame beam 2, Avoid collision damage between the corbel 101 and the frame beam 2 caused by excessive rotation range or excessive rotation.

[0052] Preferably in this embodiment, flexible waterproof material 12 is filled between the corbel 101 and the frame beam 2, between the protruding part 201 and the frame column 1, and between the corbel 101 and the protruding part 201, so as to prevent the frame column 1 from There is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com