Visible artificial sand filling and oil flooding device with injection-production liquid level adjustment function, and application thereof

An artificial and oil displacement technology, applied in the field of reservoir physical simulation, can solve the problems of cumbersome operation process, inability to simulate, lack of effective means, etc., and achieve the effect of simple device structure, convenient manufacture, and optimized well pattern layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

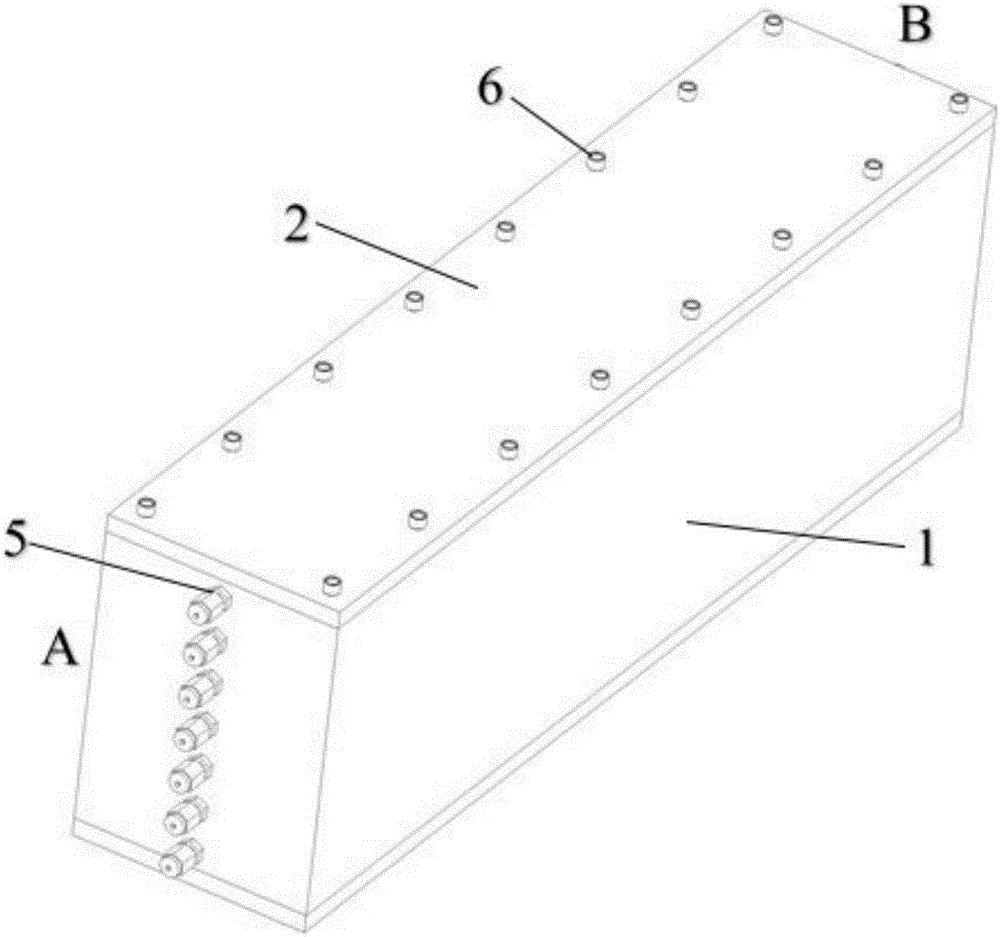

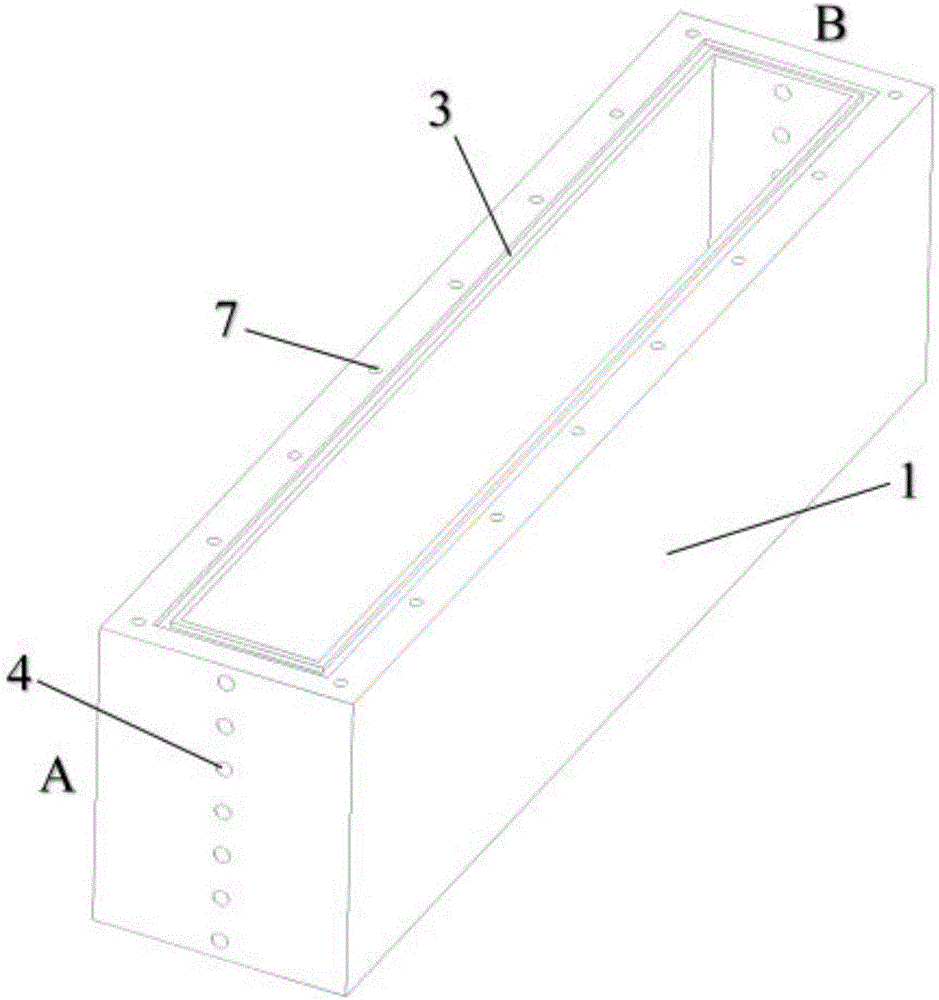

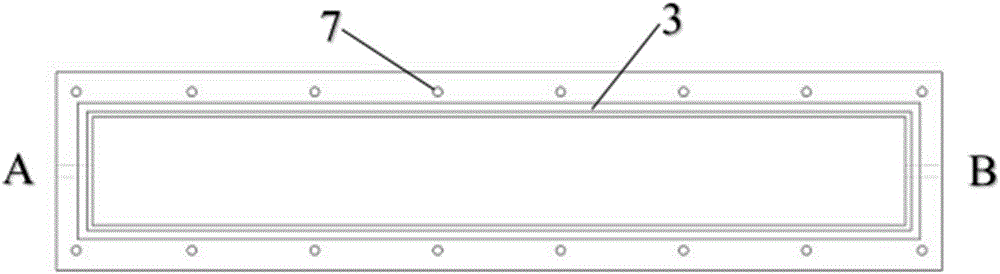

[0054] A visual artificial sand filling oil displacement device for adjusting the injection-production liquid level, such as Figure 1 to Figure 4 As shown, it includes an integrated frame 1 , a cover plate 2 , a groove 3 and a two-way joint element 5 . The cover plate 2 is composed of an upper cover and a lower cover; grooves 3 are provided on the inner wall edges of the upper and lower ends of the integrated frame 1; eight threaded holes A7 are arranged symmetrically and equidistantly on both sides of the upper and lower ends of the integrated frame 1; the cover plate 2 There is a threaded hole B 8 matching the threaded hole A7, and the cover plate 2 is fixedly connected to the integrated frame 1 through the screw 6 through the threaded hole A 7 and the threaded hole B 8; the A and B sides of the integrated frame 1 There are 7 threaded holes C4 equidistant and symmetrical respectively, and the two-way joint element 5 is fixedly connected through the threaded hole C4, wherein...

Embodiment 2

[0058] A visual artificial sand filling oil displacement device Ⅰ that can adjust the injection-production liquid level, such as Figure 5 As shown, its structure is the same as in Example 1, except that its external dimensions are 490mm long, 110mm wide, and 126mm high; four M8 threaded holes C are set on the side A of the integrated frame, which are 401 from bottom to top. ~404, four M8 threaded holes C symmetrical to side A are set on side B, 405~408 from top to bottom. Connector components.

[0059] The device is used for oil displacement operation. The specific indoor use process adopts the method described in Chinese patent CN103485769A, and the artificial sand filling oil displacement device of the present invention is used to replace the sand filling pipe assembly device in the patent. The steps of oil displacement operation are as follows:

[0060] 1) Before using the device, remove the upper cover.

[0061] 2) Prepare the sand. The sand is selected from the oil lay...

Embodiment 3

[0069] The device and operation steps that adopt are with embodiment 2, and difference is:

[0070] In step 6, the water injection rate is 0.5mL / min, and the device is subjected to water flooding operation to investigate the oil-water distribution ratio and study the law of water flooding remaining oil. This model adopts the injection-production method of low injection and high recovery, coupled with the high displacement speed, the remaining oil is less after water flooding; since this model is a sandstone hydrophilic model, the distribution of remaining oil is mainly distributed in the form of oil beads In the large pores, some remaining oil is distributed in the smaller pores.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com