Sound body leak detection device

A sound and leak detection technology, applied in the field of air tightness testing equipment, can solve the problems of low air tightness detection efficiency of the cylinder block, etc., and achieve the effects of low price, obvious detection results, and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

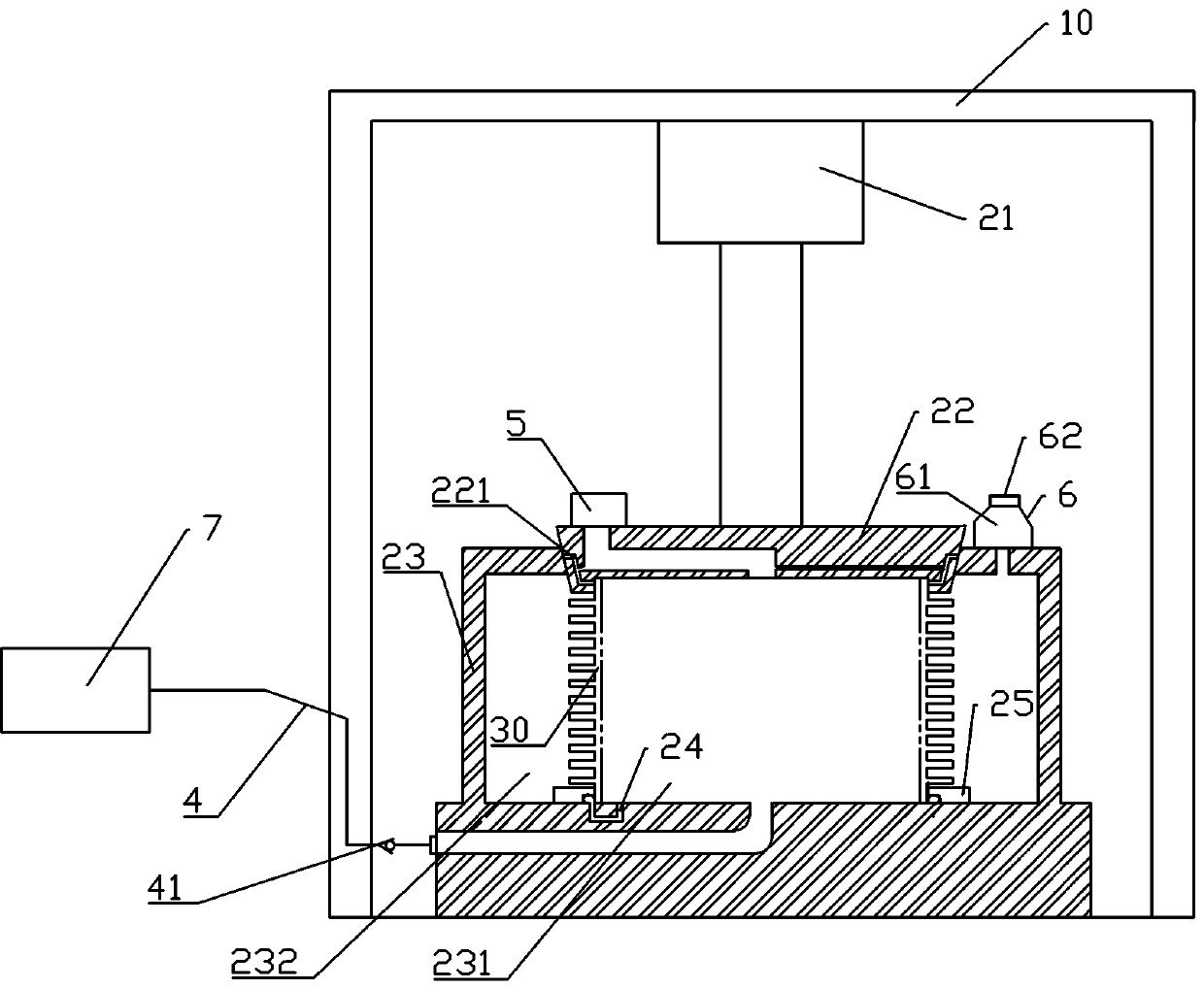

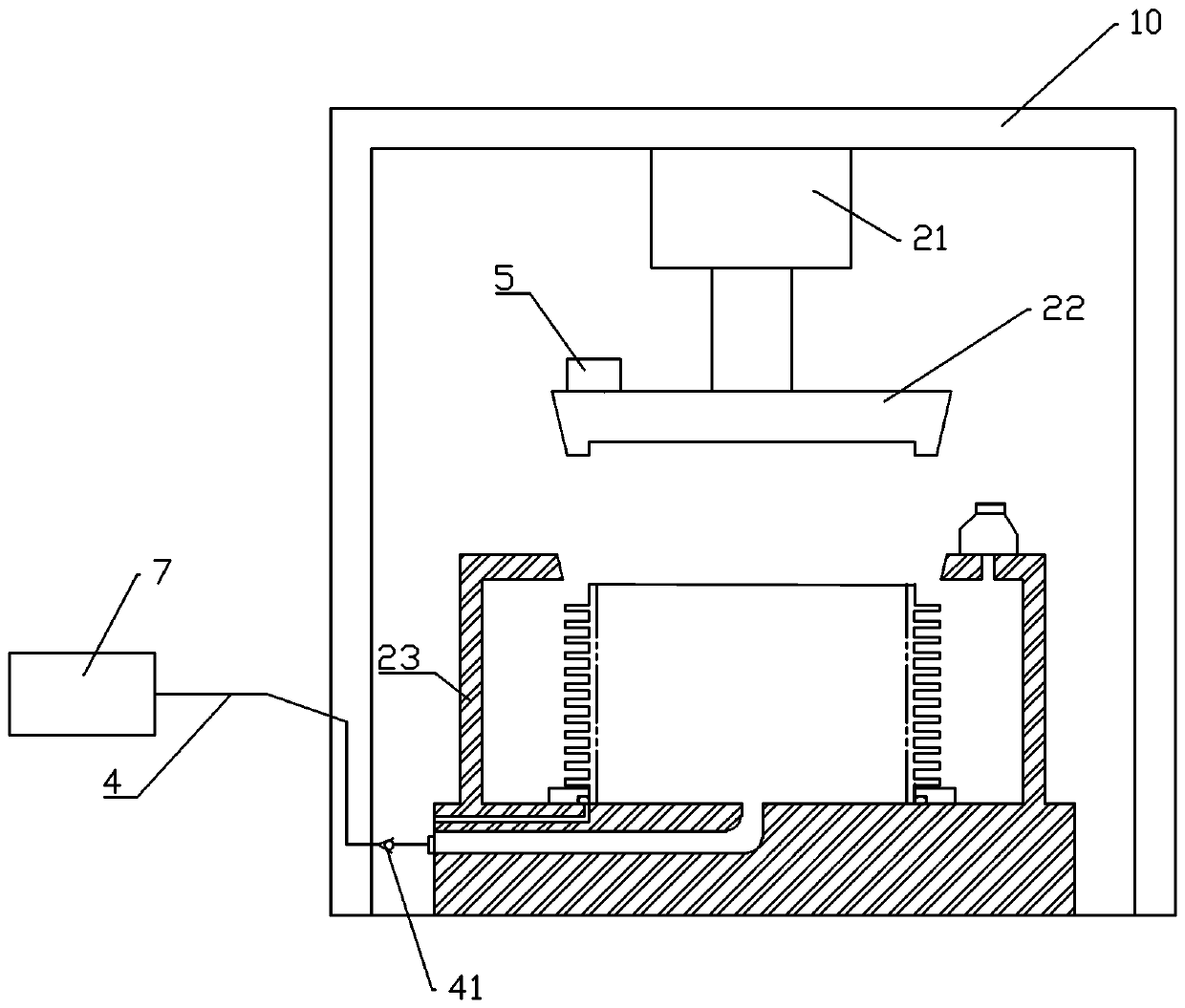

[0020] The reference signs in the accompanying drawings of the description include: frame 10, upper sealing cover 22, inflation passage 221, lower sealing box 23, compression cylinder 21, cylinder block 30, inner chamber 231, outer chamber 232, sealing passage 24, annular Spacer 25, intake pipe 4, one-way valve 41, pressure relief valve 5, sound body 6, sound cavity 61, sound port 62, air pump 7.

[0021] like figure 1 The sound body leak detection device shown includes a frame, a sealing mechanism, an air intake mechanism, an air pump and a detection mechanism; it is characterized in that the sealing mechanism includes an upper sealing cover, a lower sealing box and a compression cylinder, and the lower The sealing box is a box body that can accommodate the cylinder block and has an open upper end. The lower sealing box is fixed on the frame. The upper end of the seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com