Experimental device for preparing carbon-14 liquid sample in radioactive graphite

A liquid sample and experimental device technology, applied in the field of nuclear industry, can solve the problems of poor repeatability of results, complicated equipment, unfavorable large-scale production and promotion of use, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

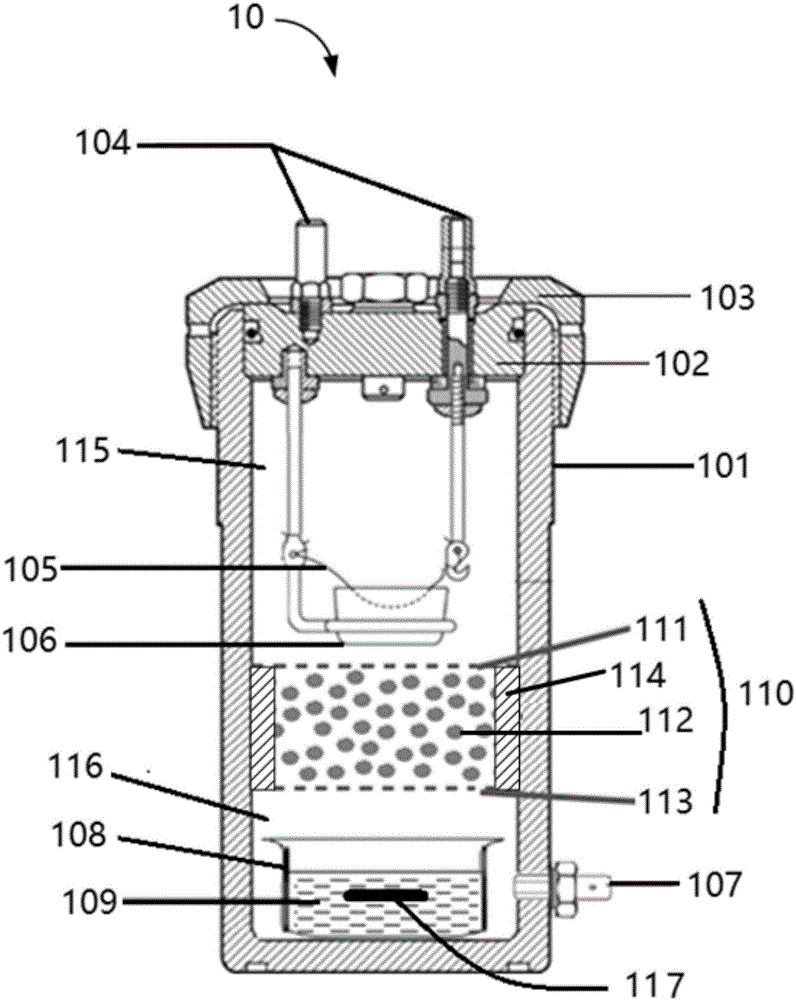

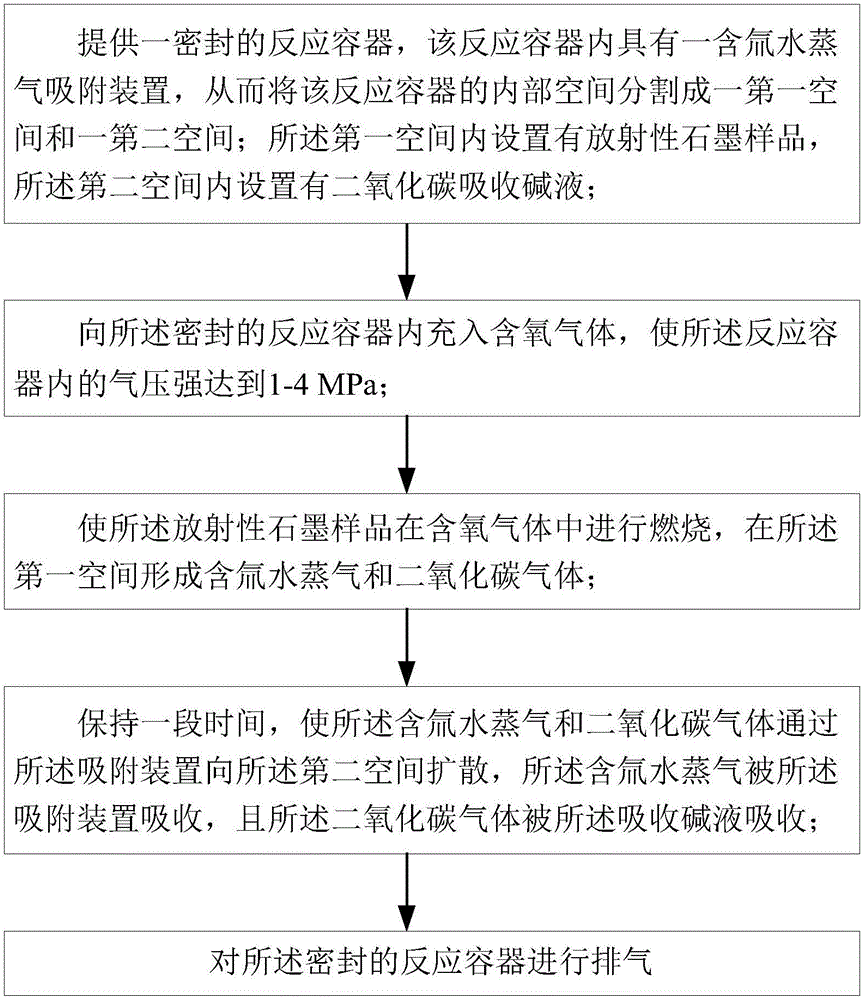

[0047] In the present embodiment, the method for preparing a liquid sample of carbon-14 in radioactive graphite by using experimental device 10 is as follows:

[0048] (1) Open the sealing cover 103 of the experimental device 10, and take out the top end cover 102;

[0049] (2) Place the sample crucible 106 on the inner support below the top end cover 102, load the quality 0.05g-0.2g radioactive graphite sample to be measured in the sample crucible 106, and connect the ignition wire 105;

[0050] (3) Put the beaker 108 equipped with a fixed volume of 5.0ml-20.0ml sodium hydroxide to absorb the lye 109 into the bottom of the pressure cylinder 101;

[0051] (4) according to needs, in the tritium water vapor adsorption device 110, pack an appropriate amount of silica gel water vapor adsorption material 112, put into this pressure-bearing steel cylinder 101 inside after sealing, guarantee that the inner wall of this pressure-bearing steel cylinder 101 is sealed by this adsorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com