A Nonlinear Inverse Control Method for Dynamic Hysteresis Compensation of Piezoelectric Actuators

A piezoelectric driver, nonlinear technology, applied in the general control system, adaptive control, control/regulation system, etc., can solve the problems affecting the positioning accuracy of the piezoelectric driver and the precision positioning accuracy, and achieve simple structure and high positioning accuracy High, good tracking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Attached below Figure 1-4 The specific implementation manner of the present invention will be further described.

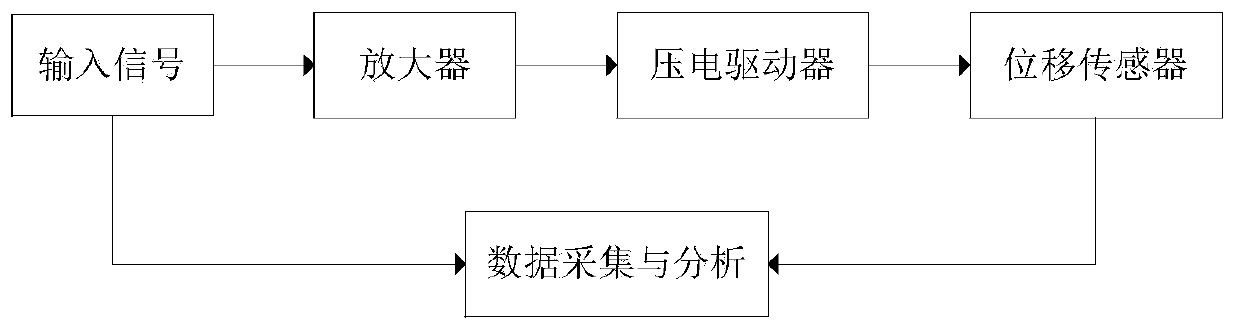

[0018] as attached figure 1 Shown is the schematic diagram of the piezoelectric actuator hysteresis characteristic experimental setup.

[0019] Piezoelectric ceramics with hysteresis characteristics are selected as the research object, including signal generator, power amplifier, laser displacement sensor and data acquisition and analysis device. The signal generator generates the input signal and stores it in the data acquisition and analysis device. The data acquisition and analysis device receives and saves the input signal generated by the signal generator and the displacement signal output by the displacement sensor, performs data processing, and draws a hysteresis curve. The power amplifier circuit can amplify the low-voltage driving signal to tens of volts or even hundreds of volts, load it on both ends of the piezoelectric ceramic, and drive the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com