Touch control panel with metal lines free of induction function

A touch panel, non-sensing technology, applied in the field of touch panels with non-sensing metal lines, can solve the problems of expensive high-resolution glass mask, large node area, and inability to break through the touch sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The embodiments of the present invention will be described in more detail below in combination with icons and symbolic symbols, so that those skilled in the art can implement them after studying this specification.

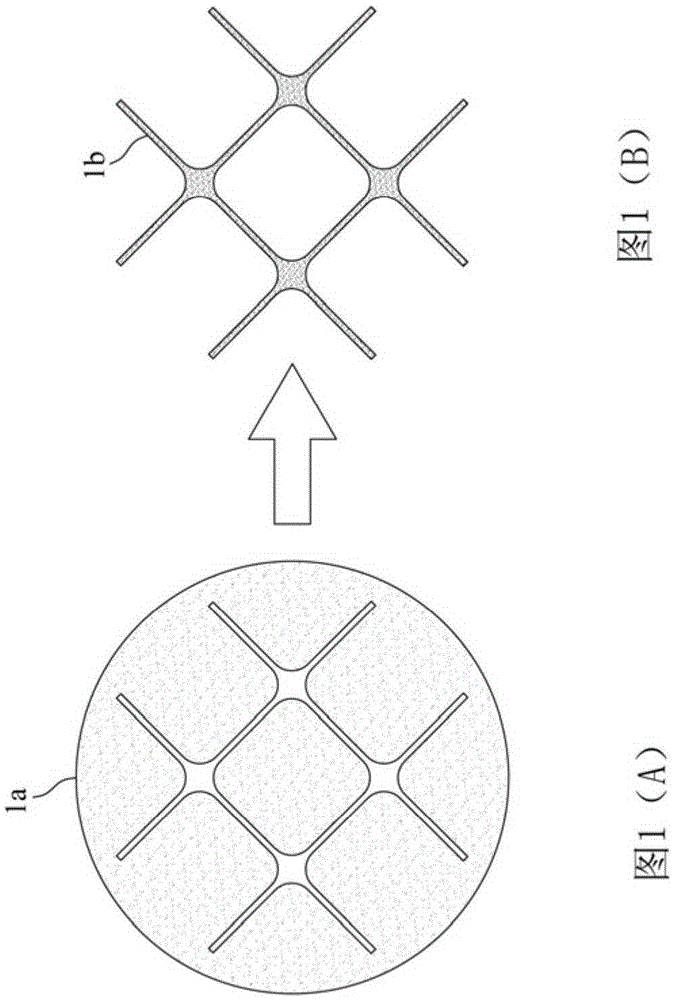

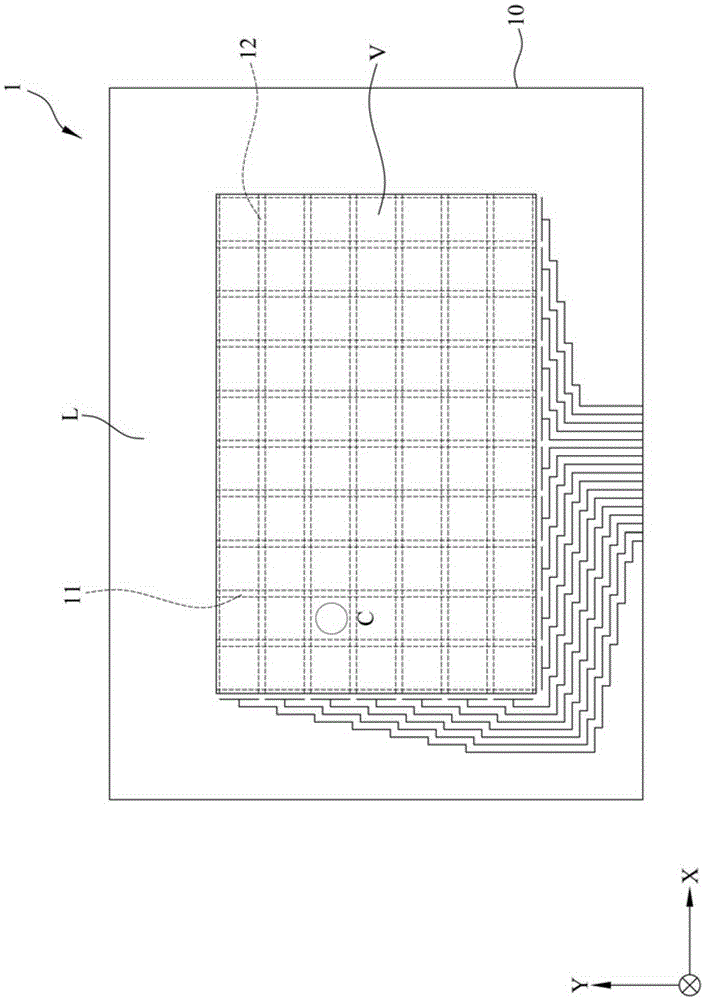

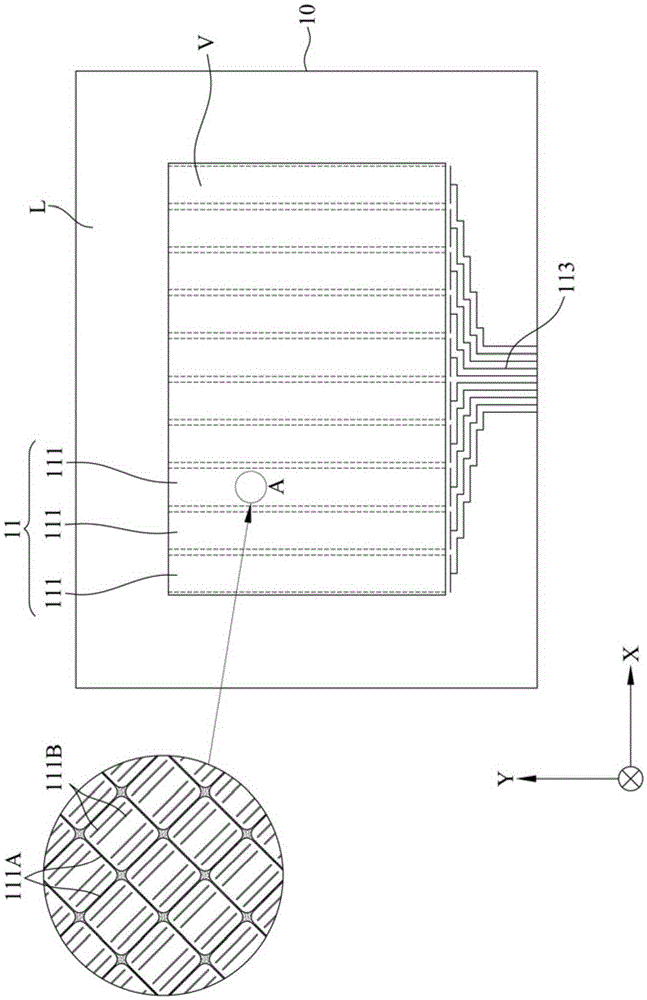

[0043] refer to figure 2 , which is a schematic diagram of a touch panel with non-sensing metal lines of the present invention. like figure 2 As shown, the touch panel 1 with metal lines without sensing function of the present invention at least includes: a light-transmitting substrate 10, a first sensing electrode 11 and a second sensing electrode 12, wherein the light-transmitting substrate 10 includes a In view of the touch area V and a peripheral line area L, the peripheral line area L is between the edge of the light-transmitting substrate 10 and the visible touch area V, and the visible touch area V is the edge of the light-transmitting substrate 10 Non-edge area, the peripheral circuit area L is the edge area of the light-transmitting substrate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com