Fracture structure, arc extinguishing chamber and breaking device

A technology of fracture structure and moving contact, which is applied in the fields of fracture structure, arc extinguishing chamber and breaking device, and can solve the problems of increasing the cost investment of the operating mechanism of the arc extinguishing chamber, the large volume of the arc extinguishing chamber, and affecting the opening and closing speed, etc. , to achieve the effect of simple structure, easy movement, and reduced cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

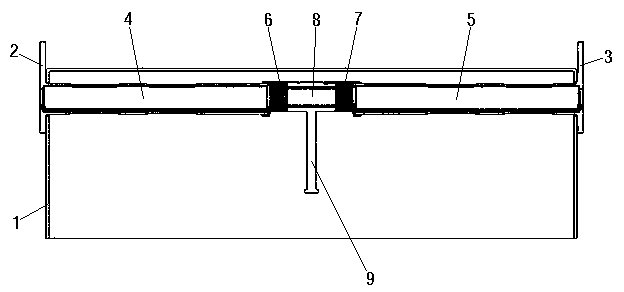

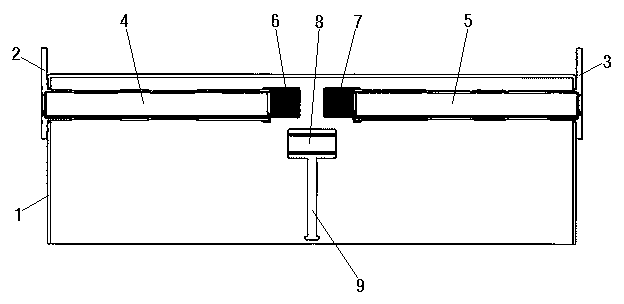

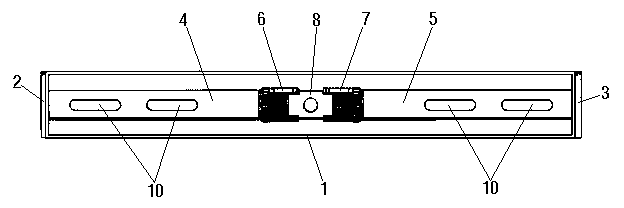

[0043] An example of a breaking device is Figure 1~Figure 3As shown, it includes an operating mechanism (not shown in the figure) and an arc extinguishing chamber connected to the operating mechanism. The arc extinguishing chamber includes a housing 1, and the left and right terminals of the housing 1 are respectively provided with a left terminal board 2 and a right terminal Plate 3, horizontal in the housing 1 (the posture of the static contact in other embodiments can be set according to needs, such as vertical, vertical setting) there are two static contacts at intervals, which are the left static contact head and right static contact. Among them, the left static contact includes a left static contact seat 4 connected to the left terminal block 2 and a left petal-shaped contact finger 6 fixed on the right end of the left static contact seat 4. In terms of shape, the petal-shaped contact finger 6 is actually It can be considered as a C-shaped contact finger, where a cut i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com