Loader

A handle and pressing piece technology, applied in the directions of transportation and packaging, electrical components, conveyor objects, etc., can solve the problems of narrow application range, inability to meet the needs of pallet pick and place, etc., to achieve the effect of expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

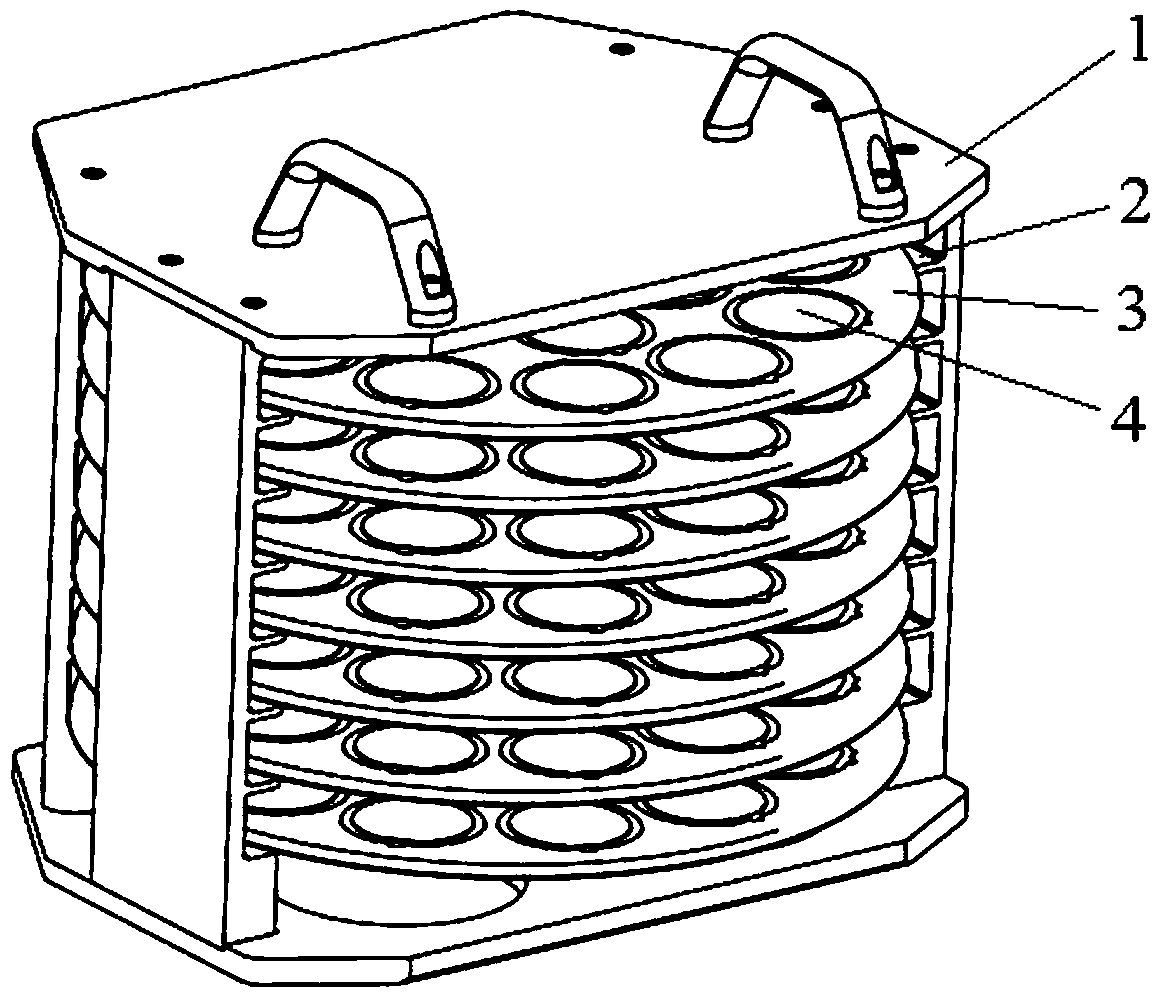

[0028] In order to enable those skilled in the art to better understand the technical solution of the present invention, the loading and unloading hand provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

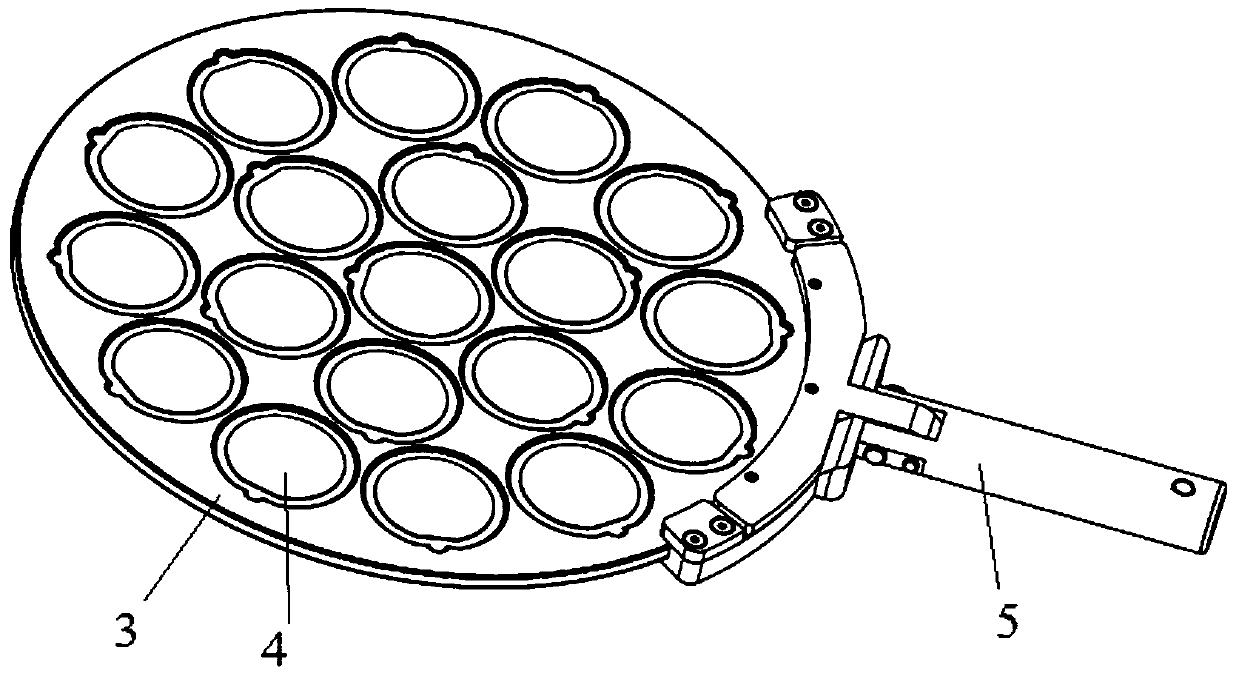

[0029] The loading and unloading hand is used to take out the cassette or put it into the tray by clamping. The film box has a plurality of slots arranged at intervals along the vertical direction, and is used for loading a plurality of trays in a one-to-one correspondence. The tray is used to carry a plurality of substrates, such as sapphire substrates or silicon substrates, and the diameter is usually 2-8 inches.

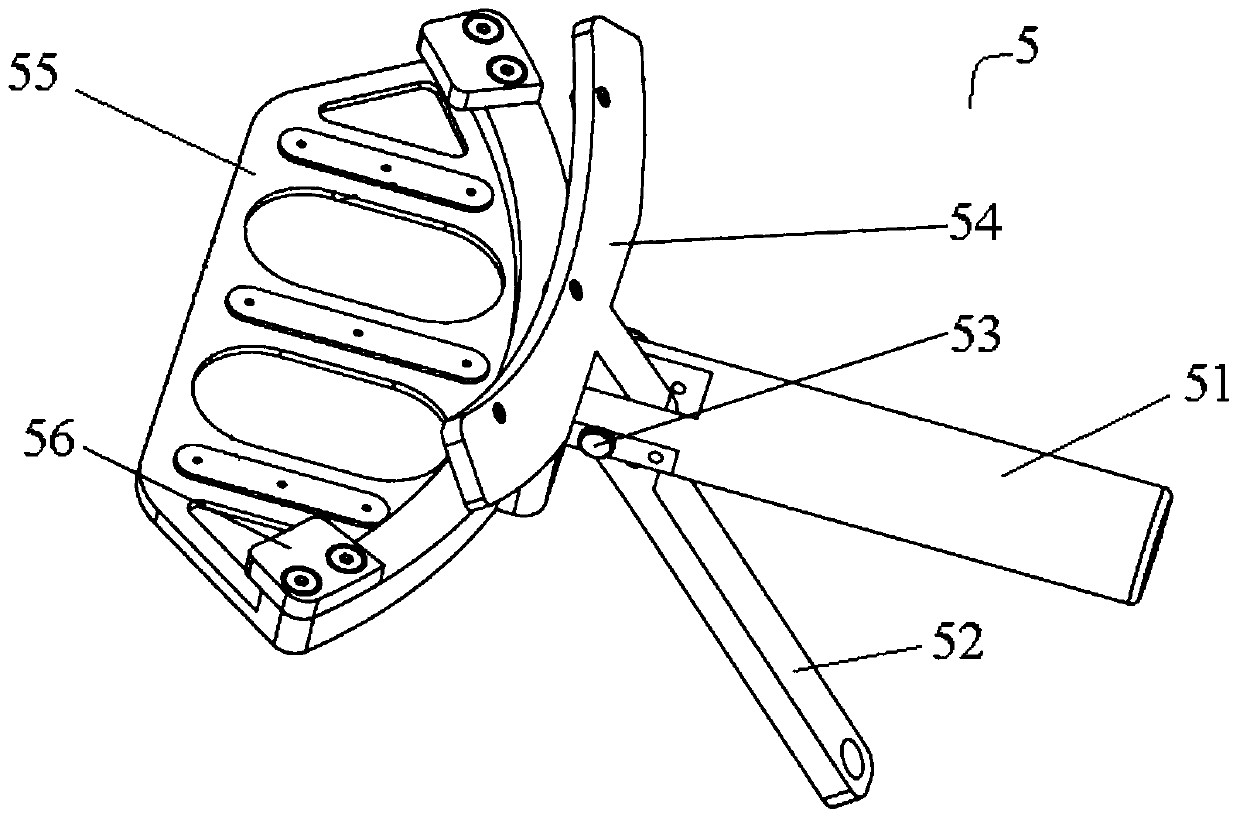

[0030] Figure 4A A top view of the loading and unloading hand provided by the embodiment of the present invention. Figure 4B for Figure 4A Partial sectional view along line A-A. Figure 4C for Figure 4B Zoom-in view of the middle I region. Please also refer to Figure 4A-Figure 4C , the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com