Organic light emitting device and preparation method thereof

An electroluminescent device and electroluminescent technology, applied in the field of lighting, can solve the problems of high manufacturing cost, complex short-circuit prevention structure process, affecting the aperture ratio of the device, etc., and achieve the effects of high product yield, simple structure and small aperture ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

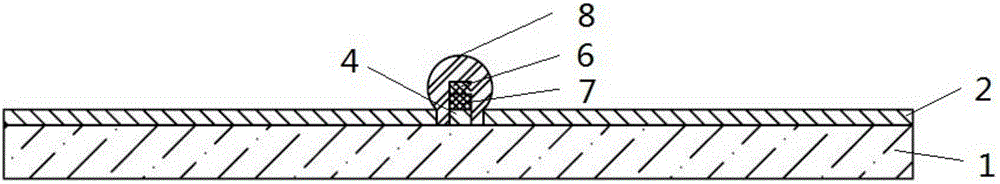

[0045] This embodiment provides an organic electroluminescent device, which includes a first electrode layer 2 , an organic layer and a second electrode layer stacked on a substrate 1 , and also includes a short-circuit prevention component directly arranged on the first electrode layer 2 .

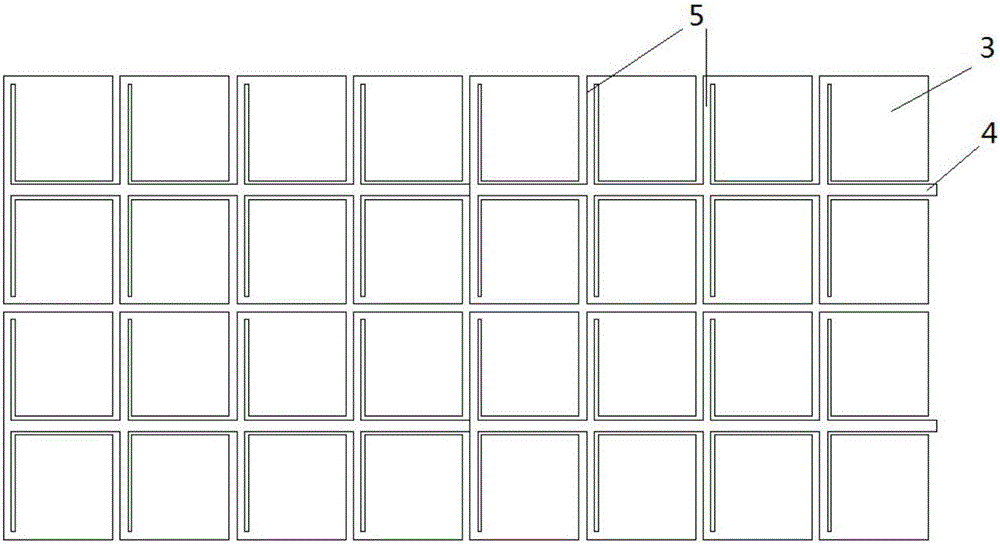

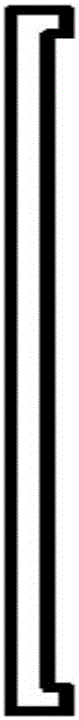

[0046] Such as figure 1 As shown, the first electrode layer 2 includes several conductive units 3 and several current-carrying bars 4 for loading current to each conductive unit 3; flow bars 5, and the flow guide bars 5 are not directly connected.

[0047] It also includes a first auxiliary electrode layer 6 directly covering the upper surfaces of the current-carrying bars 4 and the bus-guiding bars 5 , and an insulating layer 8 disposed on the first auxiliary electrode layer 6 .

[0048] As an embodiment of the present invention, in this embodiment, as image 3 As shown, the anti-short circuit assembly further includes: a second auxiliary electrode layer 7 directly disposed between the...

Embodiment 2

[0065] This embodiment provides an organic electroluminescent device and its preparation scheme. The specific structure and process are the same as in Embodiment 1, the only difference is that, as Figure 4 , Figure 5 As shown, the current guide bar 5 is arranged between two adjacent columns of conductive units 3 at intervals, and both sides of the length direction of the current guide bar 5 are provided with a number of bending parts, which are used to connect four conductive units in two adjacent columns and two rows. Unit 3.

Embodiment 3

[0067] This embodiment provides an organic electroluminescent device and its preparation scheme. The specific structure and process are the same as in Embodiment 1, the only difference is that, as Figure 6 , Figure 7 As shown, the conductive pattern 5 is hexagonal, the current guide strip 6 is herringbone, and is arranged between two adjacent rows of conductive units 3, and several bending parts are provided on the same side of the length direction of the current guide strip 5 for connecting the same The direction is adjacent to two conductive units 3 .

[0068] As an alternative embodiment of the present invention, such as Figure 8 As shown, the current guide bar 6 is herringbone or x-shaped, and can be used to connect four adjacent conductive units.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com