Motor bearing mounting method and motor

An installation method and a technology of motor bearings, which are applied in the direction of electromechanical devices, manufacturing motor generators, casings/covers/supports, etc., can solve the problems of empty position in the axial direction of the rotor, too tight friction, noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings. The following description applies in particular to brushless motors, but is not limited to use in the field of brushless motors.

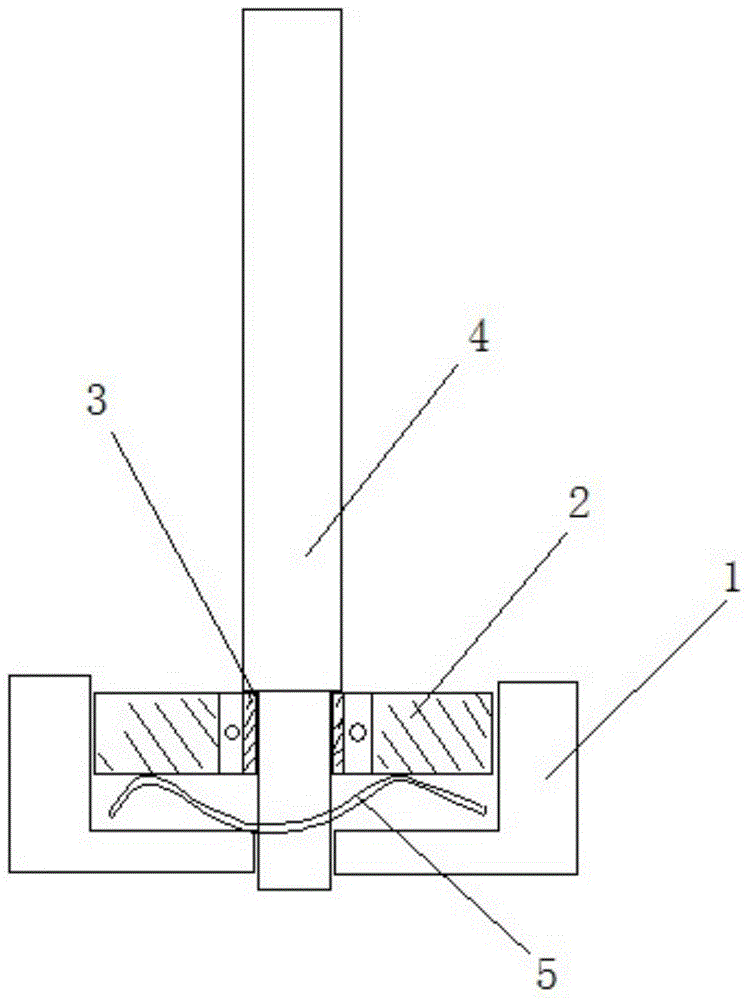

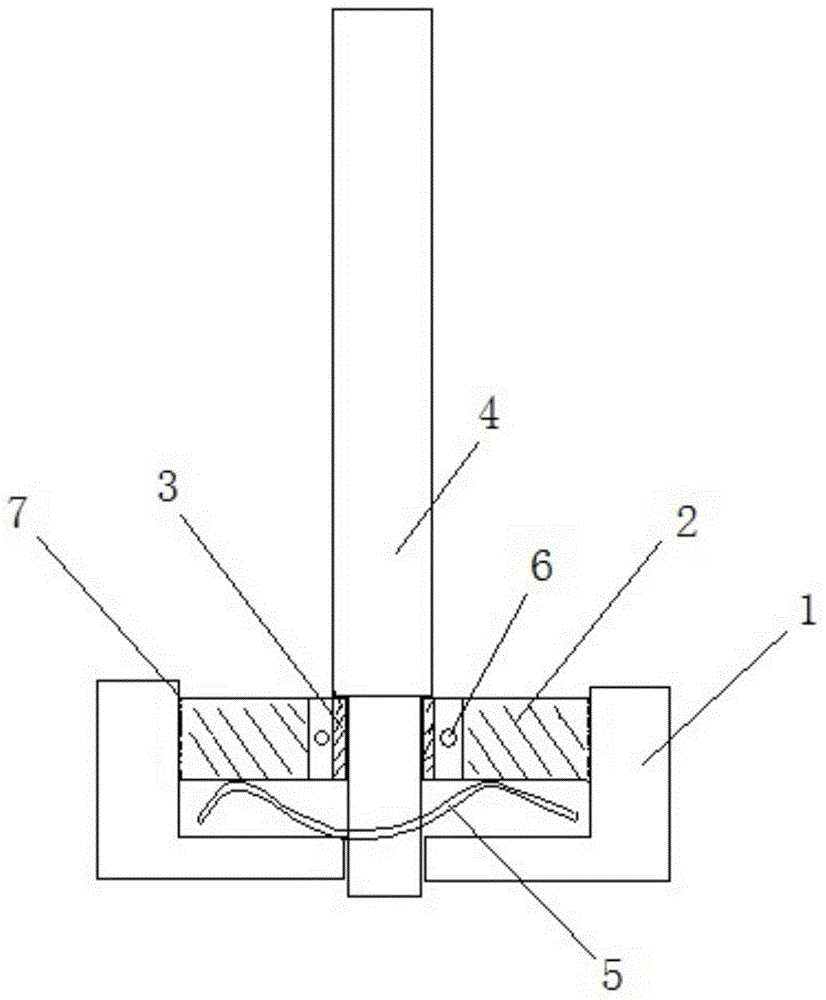

[0029] The invention provides a method for installing motor bearings. The installation method proposed by the invention solves the problems of low motor efficiency and high noise in the prior art, and the existing motors are insufficient for reference. figure 1 and figure 2 .

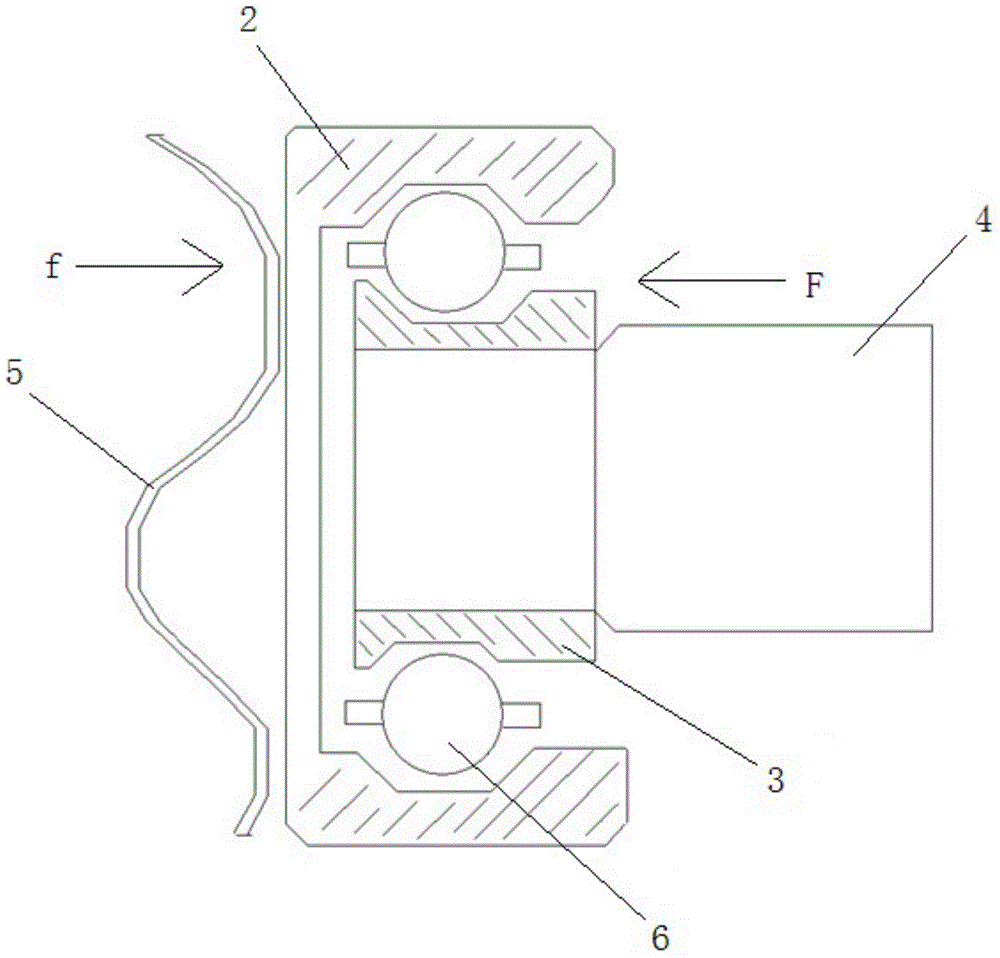

[0030] figure 1 It is a schematic diagram of the structure of the bearing relative to the end cover 1 and the motor rotor 4 in the prior art. At the position where the motor rotor 4 and the end cover 1 are connected, between the bearing and the end cover 1, and between the bearing inner ring 3 and the rotor, a fast fit is adopted. assembly method. The method of fixing the bearing outer ring 2 in the axial direction generally uses a wave-shaped elastic pad 5 to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com