Preparation method of cured fresh-keeping solution, cured fresh-keeping solution and application thereof

A fresh-keeping liquid, pickling liquid technology, applied in the preservation of meat/fish with chemicals, food ingredients as antimicrobial preservation, food science and other directions, can solve the deterioration of texture, quality deterioration, adverse effects of sales and subsequent processing problems, to achieve the effects of slowing down texture deterioration, simple preparation method and improving storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

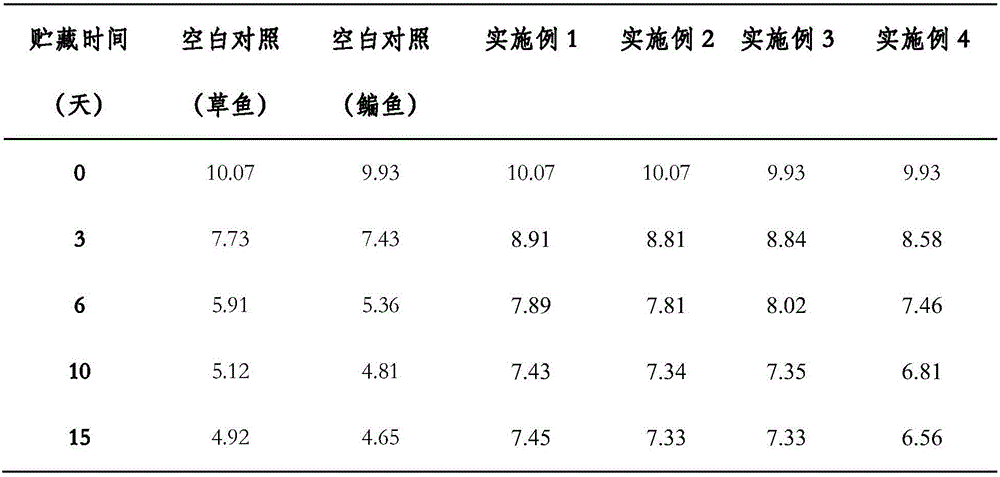

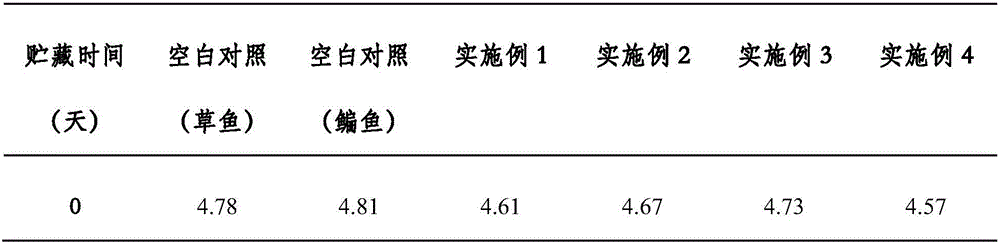

Embodiment 1

[0023] (1) Preparation of preserved fresh-keeping liquid:

[0024] Material preparation: in terms of the mass percentage of the pickling liquid, including 5% green onion, 5% ginger, 4% pepper, 3% star anise, 3% bay leaf, 3% cinnamon, 0.8% perilla, 7% salt, Rice wine 20%, polyoxyethylene sorbitan monooleate 12%, food-grade absolute ethanol 8%, allicin 2%, catechin 1%, water; (the content of evodiamine in pepper is 1.000mg / g )

[0025] Preparation of pickling solution: add onion, ginger, Chinese prickly ash, star anise, bay leaves, cinnamon bark, and perilla to water, boil at a power of 1000w for 1 hour in a slightly boiling state, then filter, add salt and rice wine to the filtrate to make pickling liquid;

[0026] Preparation of pickling preservation solution: at 25°C, under stirring at a speed of 100r / min, add polyoxyethylene sorbitan monooleate and food-grade absolute ethanol to allicin, and stir until completely mixed to obtain a dispersed phase ; under stirring at a spe...

Embodiment 2

[0033] (1) Preparation of preserved fresh-keeping liquid:

[0034] Material preparation: in terms of the mass percentage of the pickling liquid, including 4% green onion, 3% ginger, 3% pepper, 2% star anise, 2% bay leaves, 2% cinnamon, 0.5% perilla, 5% salt, Rice wine 15%, polyoxyethylene sorbitan monooleate 10%, food-grade absolute ethanol 4%, allicin 1.5%, catechin 1%, water; (the content of evodiamine in Zanthoxylum bungeanum is 1.120mg / g )

[0035] Preparation of pickling liquid: add onion, ginger, Chinese prickly ash, star anise, bay leaves, cinnamon bark, and perilla to water, boil at 1200w for 0.5h in a slightly boiling state, then filter, add salt and rice wine to the filtrate to make into a pickling solution;

[0036] Preparation of pickling preservation solution: at 20°C, under stirring at a speed of 80r / min, add polyoxyethylene sorbitan monooleate and food-grade absolute ethanol to allicin, and stir until completely mixed to obtain a dispersed phase ; under stirr...

Embodiment 3

[0043] (1) Preparation of preserved fresh-keeping liquid:

[0044] Material preparation: In terms of the mass percentage of the pickling preservation solution, it includes 5% green onion, 4% ginger, 3% pepper, 2% star anise, 1.5% bay leaf, 2% cinnamon, 0.6% perilla, 6% salt, Rice wine 15%, polyoxyethylene sorbitan monooleate 10%, food-grade absolute ethanol 6%, allicin 1%, catechin 2%, water; (the content of evodiamine in Zanthoxylum bungeanum is 1.100mg / g )

[0045] Preparation of pickling solution: add onion, ginger, Chinese prickly ash, star anise, bay leaves, cinnamon bark, and perilla to water, boil at a power of 1000w for 1 hour in a slightly boiling state, then filter, add salt and rice wine to the filtrate to make pickling liquid;

[0046] Preparation of pickling preservation solution: at 15°C, under stirring at a speed of 60r / min, add polyoxyethylene sorbitan monooleate and food-grade absolute ethanol to allicin, and stir until completely mixed to obtain a dispersed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com