Vegetable dehydrating and drying subassembly for processing dehydrated vegetables and operating method of such vegetable dehydrating and drying subassembly

A technology for dehydrated vegetables and working methods, applied in the fields of application, food processing, food science, etc., can solve problems such as reducing production efficiency and increasing process production time, and achieves the effects of reasonable structure, fast drying operation, and time saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

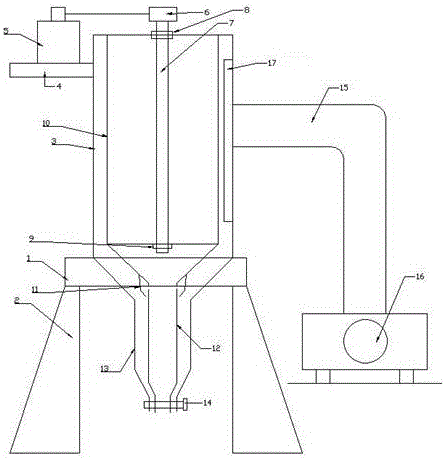

[0015] Such as figure 1 A dehydration and drying assembly for processing dehydrated vegetables is shown, including a circular mounting base 1, a leg 2 disposed under the circular mounting base 1, and a circular barrel disposed on the circular mounting base 1 3, and the motor mounting plate 4 arranged on the upper side of the circular barrel body 3, and the motor 5 arranged on the motor mounting plate 4, and the transmission shaft 7 arranged on the circular barrel body 3, and the transmission shaft 7 arranged on the circular barrel body 3 The transmission wheel 6 on the top, and the circular filter cartridge 10 arranged in the circular barrel body 3 and used in conjunction with the transmission shaft 7, and the discharge pipe 13 arranged at the bottom of the circular barrel body 3, and the discharge pipe 13 arranged at the discharge The guide tube 12 inside the tube 13 and used in conjunction with the circular filter cartridge 10, and the limit ring 11 arranged at the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com