Processing center of straw expanded feed

A technology of extruded feed and processing center, which is applied to the preservation methods of feed, animal feed, and animal feed raw materials, etc., can solve the problems of single function and low processing efficiency, and achieve the effect of saving processing space, working efficiently, and improving equipment life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

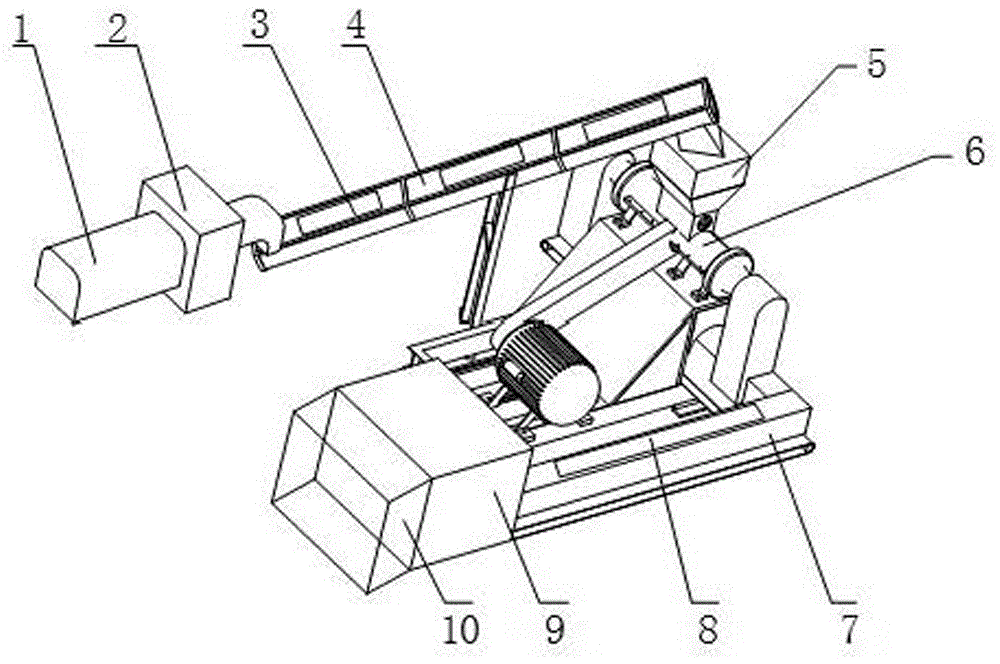

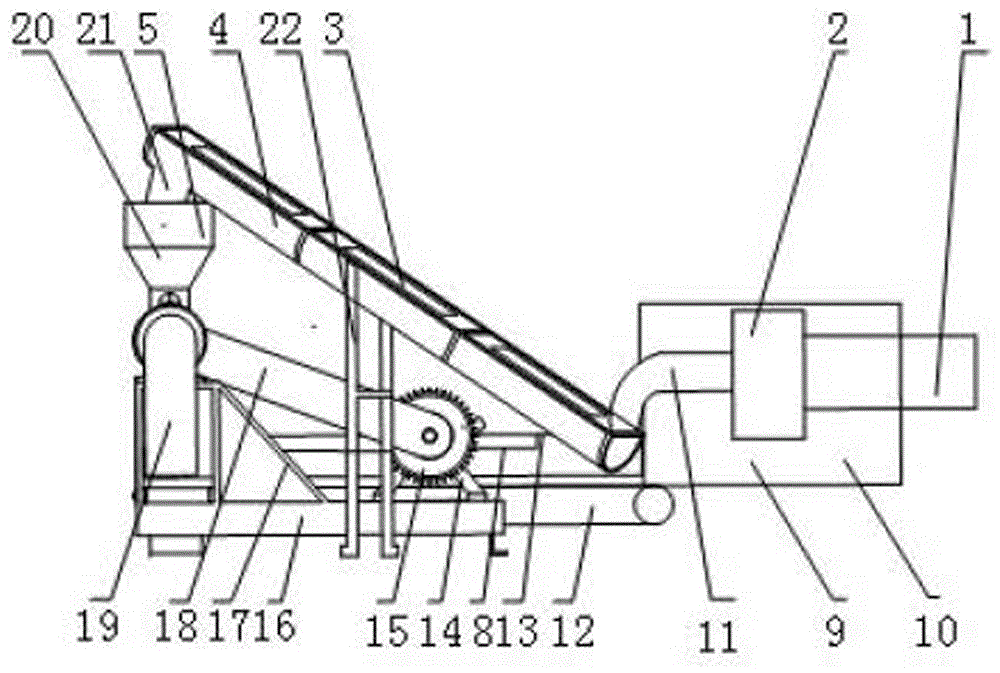

[0025] The following combination Figure 1~8 The content of the present invention will be described in detail through specific embodiments. The straw extruded feed processing center includes an input assembly, an extruded assembly and an output assembly. Among them, the feed assembly includes a primary guillotine device 2 provided with a feed inlet 1, a feed channel assembly 4 arranged at the outlet 11 of the guillotine device, a sprinkler device 3 arranged in the feed channel assembly, a water sprinkler device 3 arranged in the feed channel Secondary pressure device 5 for component outlet 21. The feed channel assembly 4 is a conveying roller with baffles that slopes upward from the feed end to the discharge end, and the conveyor belt is fixed on a horizontal plane through the feed support 22 .

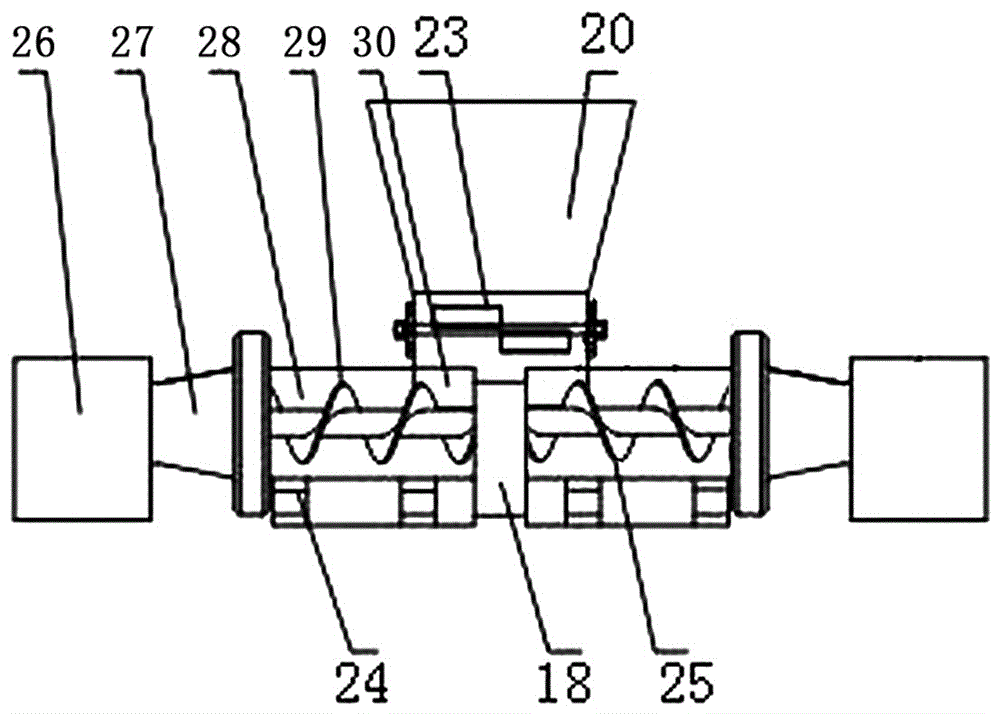

[0026] The expansion assembly includes a hopper 20 arranged at the outlet of the feed channel assembly, an anti-blocking device 23 arranged in the hopper, and an expansion device 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com