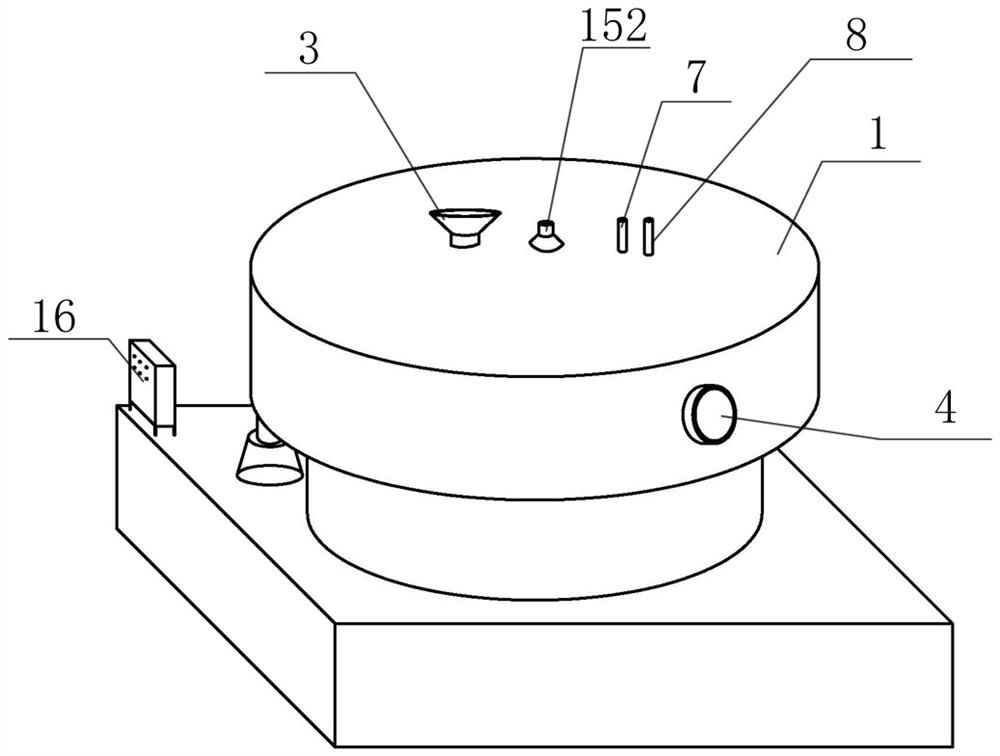

Heating unit, heating method and application of sequencing batch direct thermal desorption repair system

A repair system and heating unit technology, applied in the restoration of contaminated soil, etc., to achieve high heat exchange efficiency, low cost, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

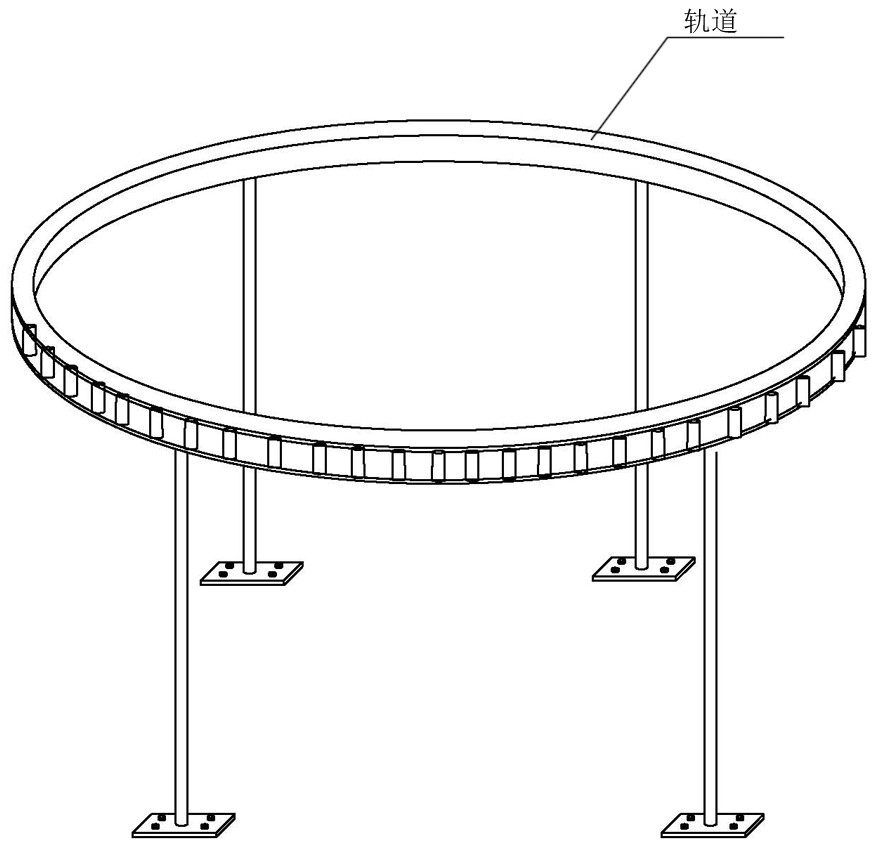

Method used

Image

Examples

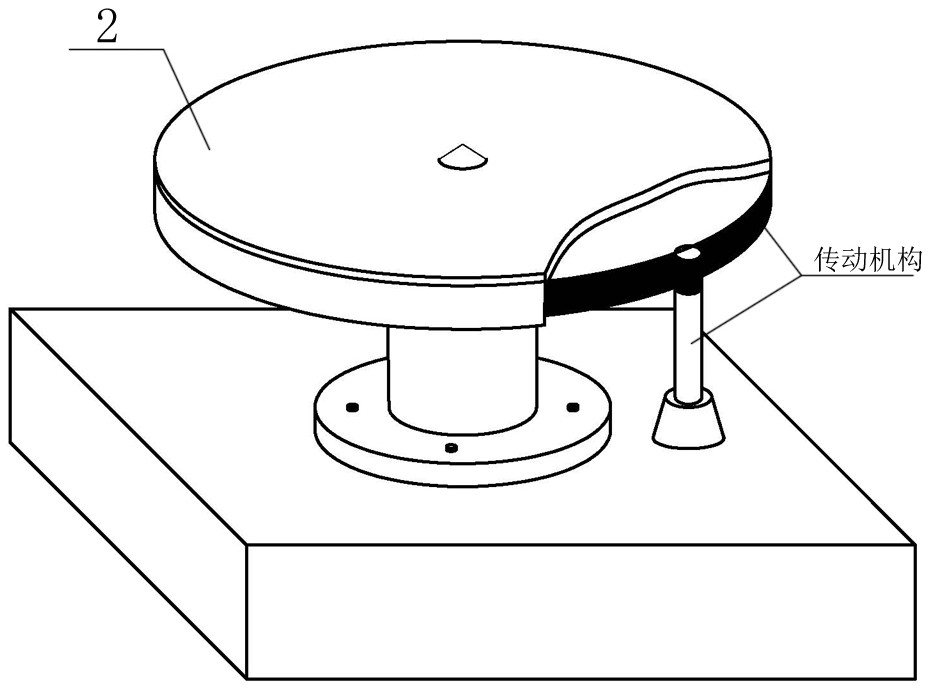

Embodiment Construction

[0059] Step 2, the soil falling onto the disc 2 moves in a circular motion along with the disc 2 . The soil rotates with the disc 2 and collides with the feeding side of the innermost soil guide plate 6, the soil moves along the feeding side of the soil guide plate 6 to the discharge side of the soil guide plate 6, and jumps into the The feed side of the soil guide plate 6 adjacent to the outer circle until the soil moves to the discharge side of the soil guide plate 6 of the outermost circle. Promote soil guide plate 6 successively from outside to inside then, make be covered with soil on the whole disk 2. The automatic control mechanism 16 controls the combustion nozzle 5 to continue heating the soil for a period of time. After the set heating period is reached, the automatic control mechanism 16 controls the crushing roller 11 to lower to crush the heated soil particles, and then controls the crushing roller 11 to rise , then control the rake plow 12 to be lowered to comb ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com