Smoke oil and preparation method thereof

A technology of tobacco and tobacco powder, which is applied in the field of electronic cigarettes, can solve the problems of being unable to restore the smoking experience of traditional cigarettes, and it is difficult to simulate the aroma of traditional cigarettes, so as to achieve the effects of reducing stimulation, rounding the taste of smoking, and improving the aftertaste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a method for preparing smoke oil, comprising the following steps:

[0040] Dissolving heterocyclic fragrance bases, alcohol fragrance groups, acid fragrance groups, ketone fragrance groups, phenolic fragrance groups and aldehyde fragrance groups in propylene glycol to obtain tobacco fragrance bases;

[0041] Cocoa tincture is coated on the tobacco leaves, alcoholized and roasted, crushed to make tobacco powder, heated, soaked and extracted to obtain tobacco rectification liquid;

[0042] The tobacco fragrance base and the tobacco rectification liquid are dissolved in the organic solvent, and filtered to obtain a filtrate, which is the e-liquid.

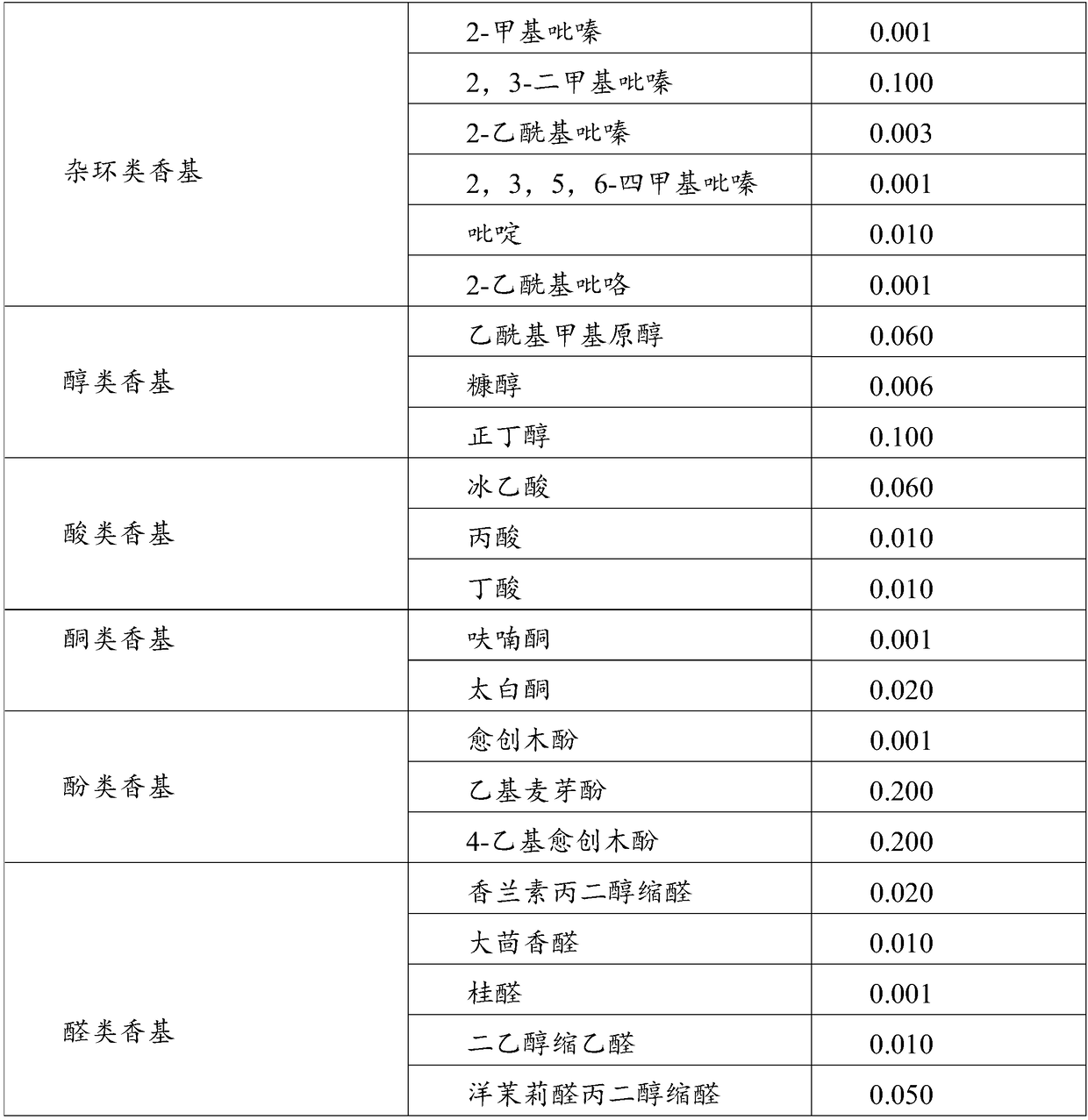

[0043]Further, the parts by mass of each component in the tobacco fragrance base are as follows: 0.116-0.323 parts for heterocyclic fragrance groups, 0.166-0.769 parts for alcohol fragrance groups, 0.08-0.375 parts for acid fragrance groups, and 0.08-0.375 parts for ketone fragrance groups. ...

Embodiment 1

[0046] The preparation of tobacco rectification liquid comprises the following steps:

[0047] Select the tobacco leaves of oriental tobacco, weigh the tobacco leaves and cocoa tincture respectively, so that the mass ratio is 1:0.5, evenly coat the cocoa tincture on the tobacco leaves, and then alcoholize the tobacco leaves for 1 hour under constant temperature and humidity conditions, and then place them in an oven Dry at 60°C until its moisture content is 12.5%;

[0048] Grind the tobacco leaves obtained through the above treatment into tobacco powder with a pulverizer, weigh some tobacco powder, place it in a round bottom flask connected with a condensation reflux device, heat it to 200°C for 45 minutes, and cool it to room temperature to obtain Tobacco distillates;

[0049] The mass ratio of ethanol with a concentration of 70% to the obtained tobacco rectified product is 1:1 to prepare a mixture, soak and extract it for 12 hours, and suction filter to obtain tobacco recti...

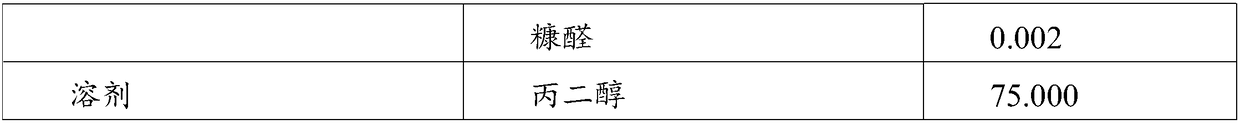

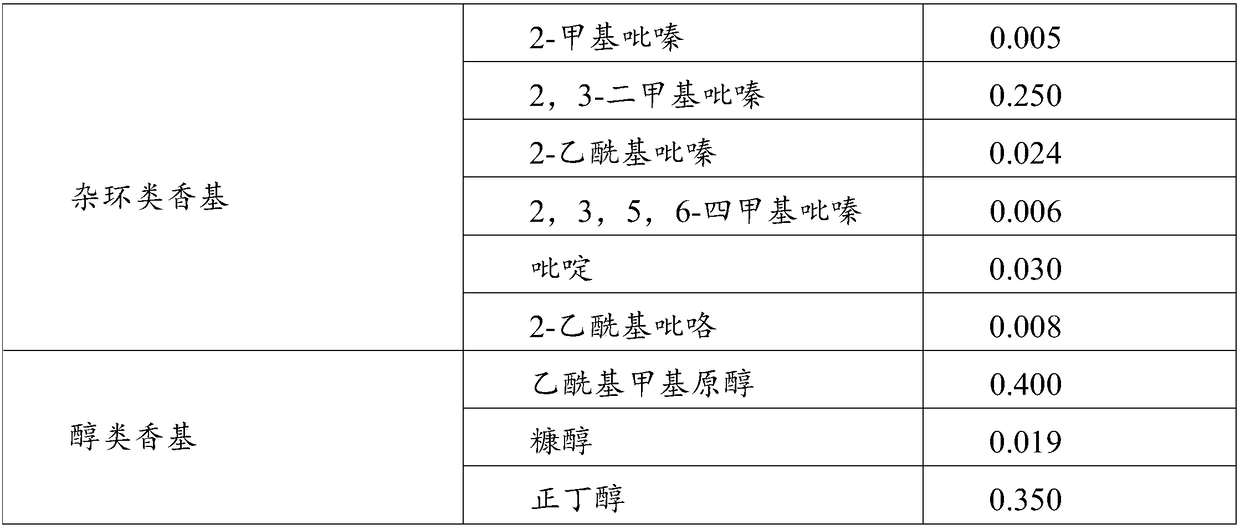

Embodiment 2

[0058] The preparation of tobacco rectification liquid comprises the following steps:

[0059] Select the tobacco leaves of oriental tobacco, weigh the tobacco leaves and cocoa tincture respectively, so that the mass ratio is 1:4, evenly coat the cocoa tincture on the tobacco leaves, and then alcoholize the tobacco leaves for 3 hours under constant temperature and humidity conditions, and then put them in an oven Dry at 100°C until its moisture content is 12.5%;

[0060] Grind the tobacco leaves obtained through the above treatment into tobacco powder with a pulverizer, weigh some tobacco powder, place it in a round-bottomed flask connected with a condensation reflux device, heat it to 450°C for 45 minutes, and cool it to room temperature to obtain Tobacco distillates;

[0061] The mass ratio of ethanol with a concentration of 95% to the obtained tobacco rectification product is 3:1 to prepare a mixture, soak and extract it for 24 hours, and then suction filter to obtain toba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com