Preparation method of concentrated buffalo horn granules

A technology of buffalo horn and concentrated water, which is applied in the field of medicine, can solve the problems of difficult raw material preparation and granule machine separation, and achieve the effects of good granule fluidity, simplified process flow, and stable machine filling volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

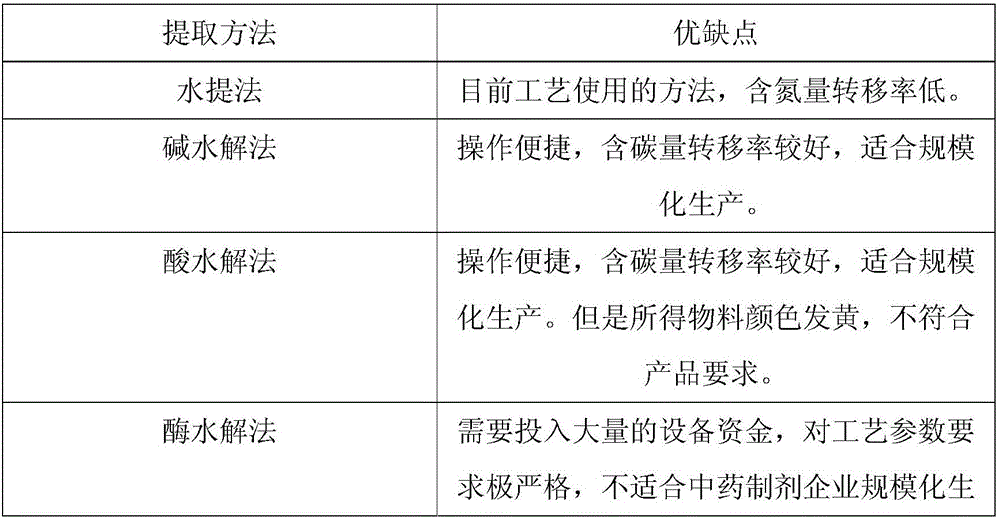

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: the preparation method of granule

[0041] Prescription: buffalo horn 1050g

[0042] Preparation method:

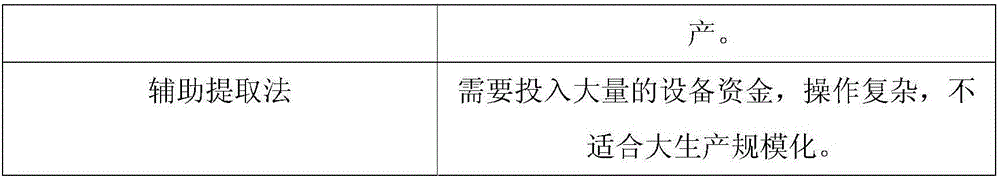

[0043] (1) Preparation of buffalo horn concentrated powder: wash buffalo horn, saw off, remove horn plug, and split into small pieces. Select the solid core part of the tip (corner tip), sterilize the corner tip with steam, and crush it into a 120-mesh fine powder. After the remaining part (horn pile) is roughly crushed, decoct twice, add 8 times the amount of 0.1mol / L sodium hydroxide aqueous solution for extraction for 7 hours each time, combine the decoction liquid, and adjust the pH of the filtrate to 7 with 10% hydrochloric acid solution. Stand still for 12 hours, filter, concentrate the filtrate to 1 / 5-1 / 6 of the weight of the horn pile powder, add the above horn tip fine powder, mix well, dry it in a vacuum oven under reduced pressure, and crush it into 120 mesh fine powder Powder, sieved, that is.

[0044] (2) Take concentrated buffalo hor...

Embodiment 2

[0045] Embodiment 2: the preparation method of granule

[0046] Prescription: buffalo horn 1050g

[0047] Preparation method:

[0048] (1) Preparation of buffalo horn concentrated powder: wash buffalo horn, saw off, remove horn plug, and split into small pieces. Select the solid core part of the tip (corner tip), sterilize the corner tip with steam, and crush it into a 120-mesh fine powder. After the remaining part (corner pile) is roughly crushed, decoct twice, add 9 times the amount of 0.1mol / L sodium hydroxide aqueous solution for extraction for 7 hours each time, combine the decoction liquid, and adjust the pH of the filtrate to 7 with 10% hydrochloric acid solution. Stand still for 12 hours, filter, concentrate the filtrate to 1 / 5-1 / 6 of the weight of the horn pile powder, add the above horn tip fine powder, mix well, dry it in a vacuum oven under reduced pressure, and crush it into 120 mesh fine powder Powder, sieved, that is.

[0049] (2) Take concentrated buffalo h...

Embodiment 3

[0050] Embodiment 3: the preparation method of granule

[0051] Prescription: buffalo horn 1120g

[0052] Preparation method:

[0053](1) Preparation of buffalo horn concentrated powder: wash buffalo horn, saw off, remove horn plug, and split into small pieces. Select the solid core part of the tip (corner tip), sterilize the corner tip with steam, and crush it into a 120-mesh fine powder. After the remaining part (corner pile) is roughly crushed, decoct twice, add 10 times the amount of 0.1mol / L sodium hydroxide aqueous solution for extraction for 7 hours each time, combine the decoction liquid, and adjust the pH of the filtrate to 7 with 10% hydrochloric acid solution. Let it stand for 12 hours, filter, concentrate the filtrate to 1 / 5-1 / 6 of the amount of horn pile powder, add the above horn tip fine powder, mix well, dry it in a vacuum oven under reduced pressure, and crush it into 120 mesh fine powder Powder, sieved, that is.

[0054] (2) Take concentrated buffalo horn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com