Wig transplanting machine

A technology of wigs and hair strands, which is applied in the field of automatic machinery for making puppet wigs, can solve the problems of unguaranteed quality of hair transplants, poor uniformity of hair transplants, and low production efficiency, and achieves fast hair transplantation, low labor costs, and high production efficiency. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

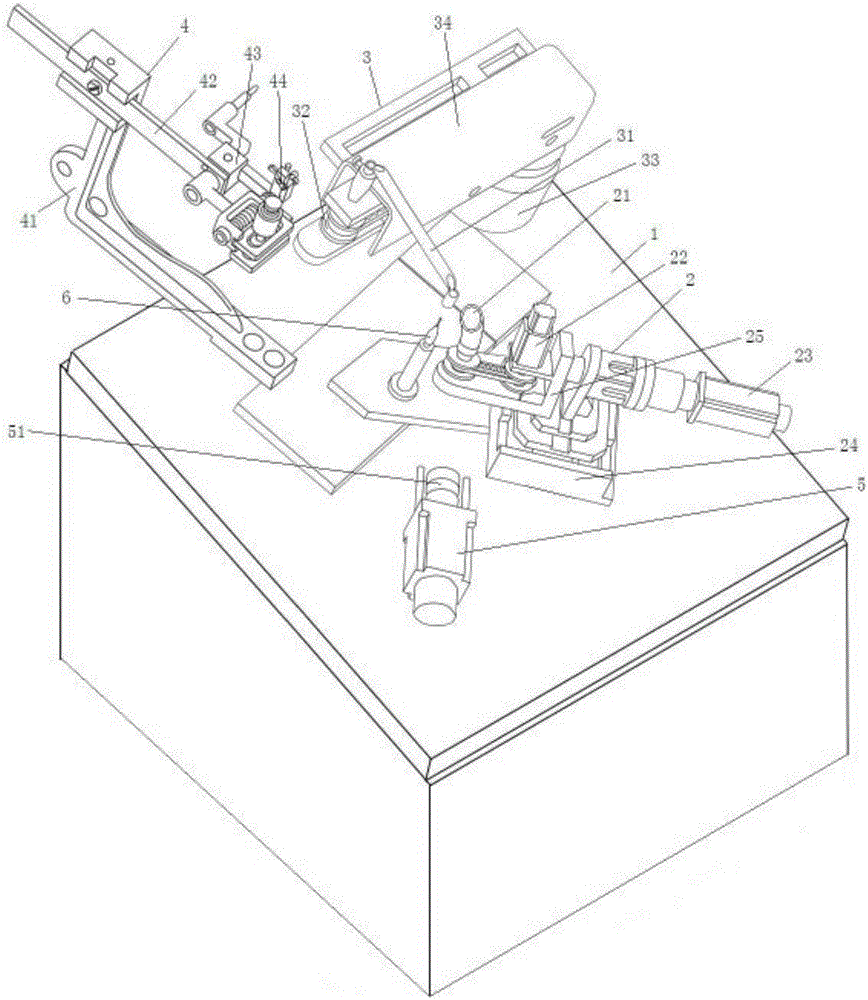

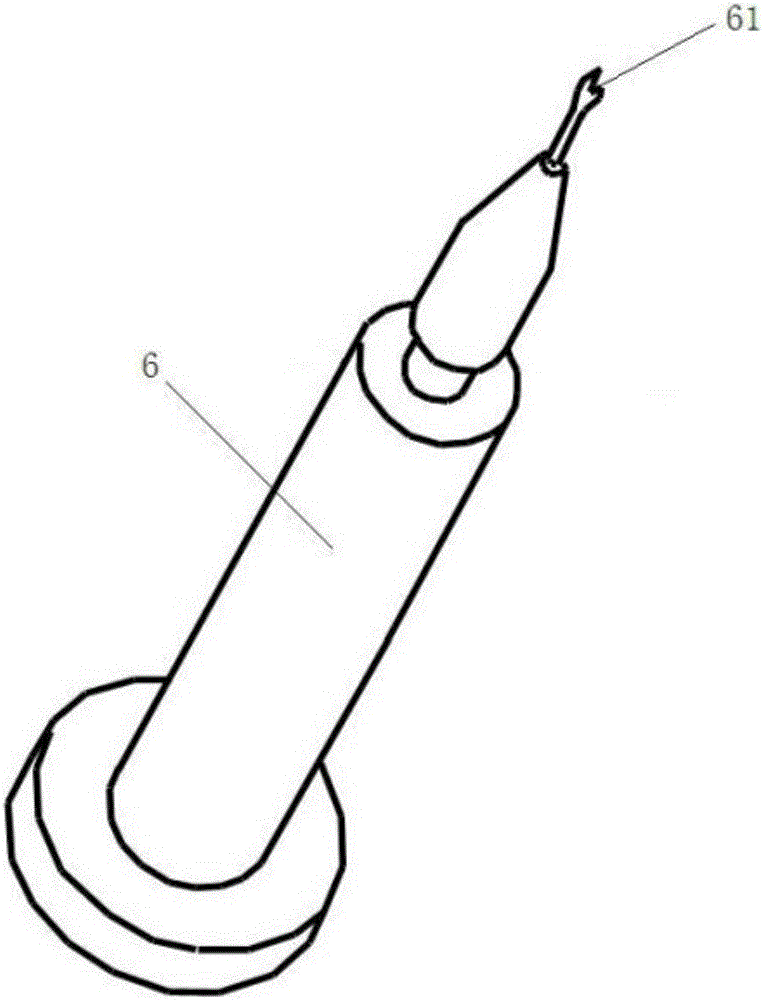

[0014] refer to figure 1 , figure 2 , a kind of wig hair transplanting machine of the present invention, comprises bottom box 1, and bottom box is provided with false head three-dimensional rotating device 2, rotating hair sending device 3, measuring and cutting hair device 4, wig blowing device 5, described wig The front bottom box of the head three-dimensional rotating device is provided with a pin 6 that can move up and down, and the front end of the false head three-dimensional rotating device is provided with a false head fixing seat 21. Surface rotating motor 23, the vertical rotating motor is fixed on the base 24 of the false head three-dimensional rotating device, the output shaft of the vertical rotating motor is connected with a transmission of a vertical rotating frame 25, and the flat rotating motor is located on the vertical rotating frame, The bottom of the false head holder is rotatably connected to the bottom of the façade rotating frame, the output shaft of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com