Novel agitating vane

A technology of mixing blades and blades, which is applied in the field of new mixing blades, can solve the problems of being unable to bear the stirring at high speeds, the sludge is not stirred violently enough, and the service life is not high, and achieves the advantages of increased thickness, enhanced force bearing capacity, and large stirring force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention will be further described, and protection scope of the present invention is not limited to following:

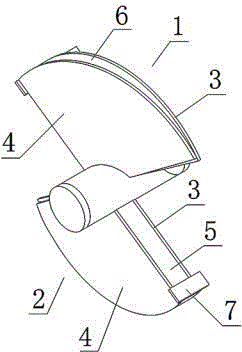

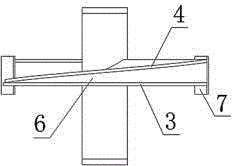

[0015] like figure 1 As shown, the new type of stirring blade includes blade A1 and blade B2. The blade A1 and blade B2 have the same mechanism and are arranged on the stirring shaft in an "8" shape. Both blade A1 and blade B2 include the first blade side plate 3, The second blade side plate 4, the blade end plate 5 and the arc plate, the first blade side plate 3 is arranged perpendicular to the stirring shaft and parallel to the end face of the stirring shaft, and the second blade side plate 4 is perpendicular to the stirring shaft The shaft is set and is close to one side of the first blade side plate 3 and the other side is opened at a certain angle. The second blade side plate 4 plays the role of pushing the sludge. The first blade side plate 3 and the second blade side plate 4 corners are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com