Device and method for monitoring oil film thickness of in-use ball mill sliding bearing

A technology for sliding bearings and oil film thickness, applied in measuring devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems such as equipment property loss, bad social impact, casualties, etc., to ensure accuracy, avoid equipment downtime and The effect of production loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

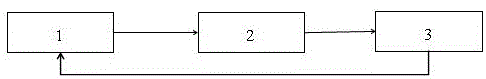

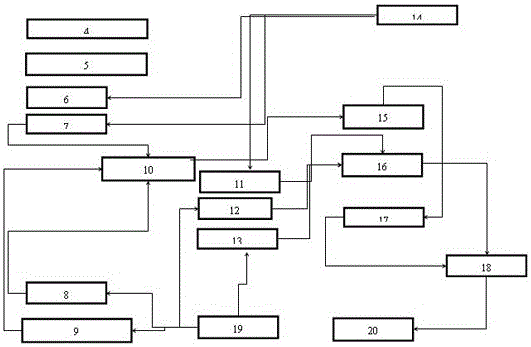

[0024] Further illustrate the concrete technical scheme of the present invention below in conjunction with accompanying drawing, as Figure 1-5 shown.

[0025] An oil film thickness monitoring device for a sliding bearing of a ball mill in use, comprising: a data acquisition process part 1, a data processing and transmission part 2, a data analysis and control part 3; the data acquisition process part 1 is connected to a data processing and transmission part 2, and the data processing and transmission part 2 is connected with the data analysis and control part 3, and the data analysis and control part 3 is connected with the data acquisition process part 1.

[0026] Data acquisition process part 1 includes: pulse transmitter mounting bracket 4, ultrasonic sensor mounting bracket 5, pulse transmitter 6, ultrasonic sensor 7, ultrasonic piezoelectric element 8, ultrasonic pulse transmitter receiver 9, precision temperature sensor II11, patch sensor 12. Accurate temperature senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com