Paper shredder and working method thereof

A paper shredder and paper shredding technology, which is applied in papermaking, textile and papermaking, fiber raw material processing, etc., can solve the problems of ink processing, inability to guarantee information leakage prevention, and inability to solve leakage prevention, so as to save time and prevent information leakage , the effect of increasing the difficulty of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

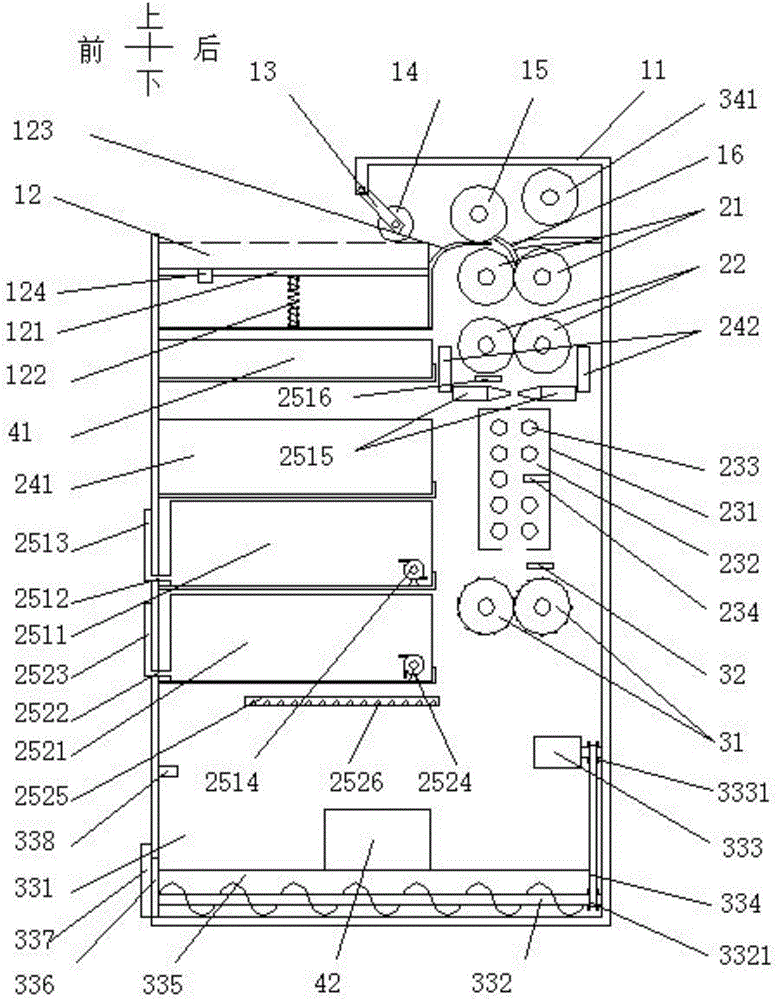

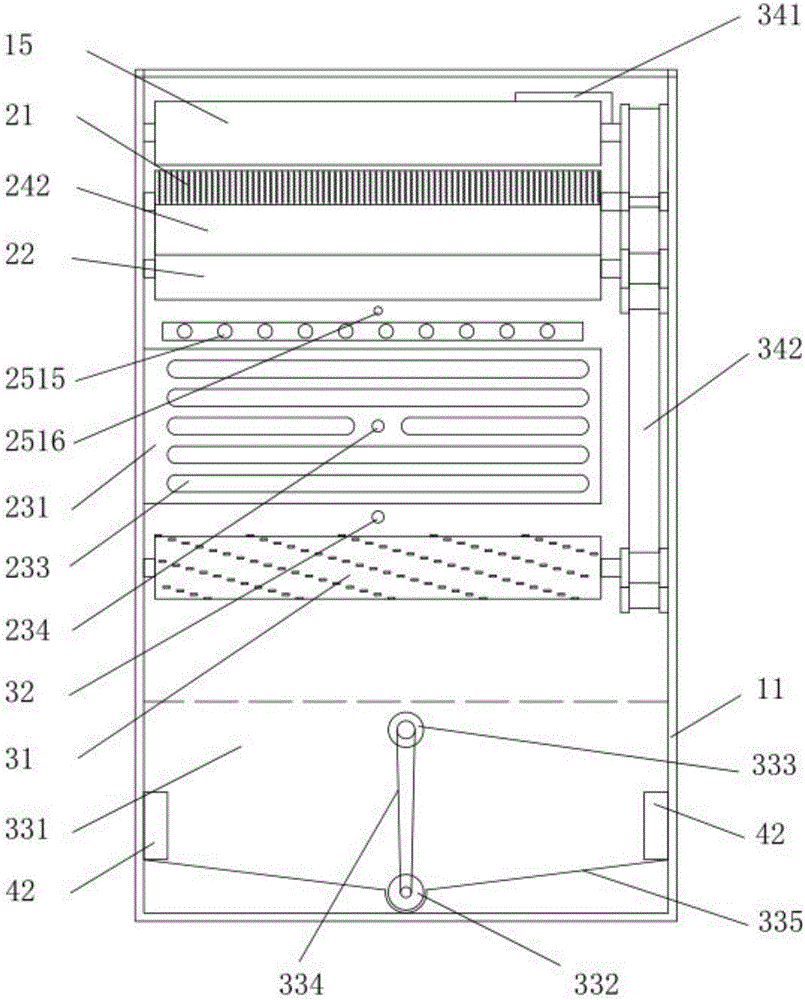

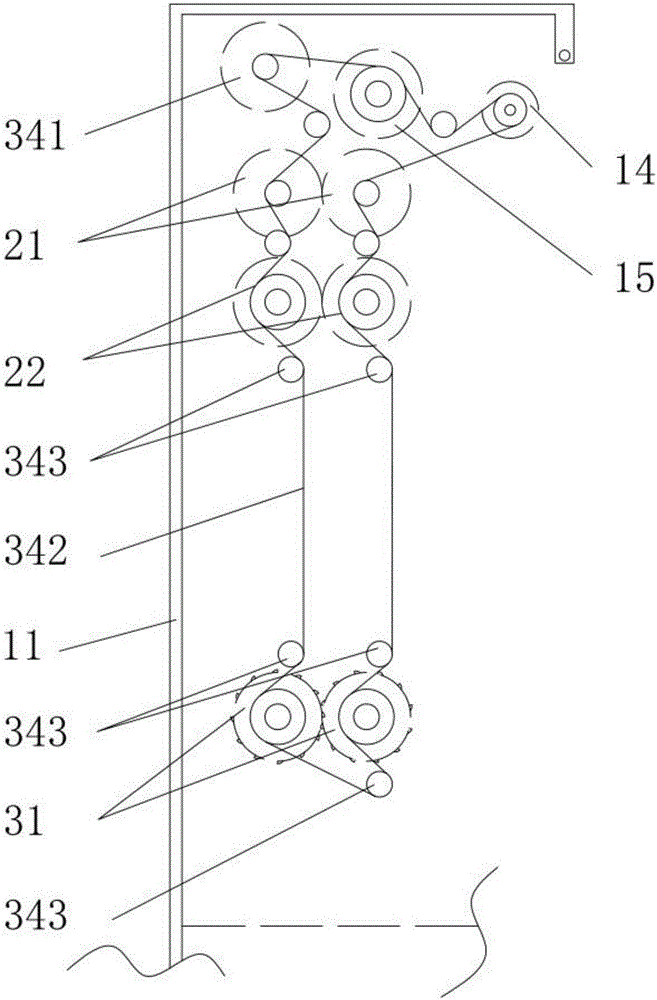

[0055] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0056] In addition, it should be noted that, unless otherwise specified or pointed out, the terms "front", "rear", "left", "right", "upper", "lower" and other descriptions that may be involved in the specification are only used to distinguish The various components, elements, steps, etc. in the specification are not used to represent the logical relationship or sequence relationship between the various components, elements, and steps.

[0057] The related words of "working" of "shredding motor" and "discharging motor" are only used for convenience of description, and do not represent the specific running direction of the motor.

[0058] The present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com