Mineral processing method of antimony sulfide ore

A technology of antimony sulfide ore and beneficiation method, which is applied in flotation, solid separation, etc. It can solve the problems of operational safety impact, low lead content of antimony concentrate, and large dosage of chemicals, so as to reduce production cost and have strong collection capacity , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

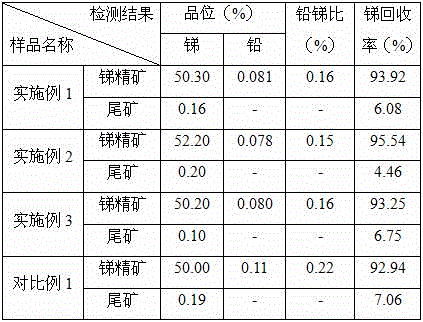

Embodiment 1

[0026] Crush the raw antimony sulfide ore until the particle size is less than 14mm, grind the ore until the particle size is 200 mesh, and the mass percentage of the sieve is 72.50%. and three times of beneficiation to obtain antimony concentrate; among them, in the rough selection, 70g lead nitrate / t antimony ore is used as the activator, and 120gMA-3 / t antimony ore and 95g ethyl disulfide / t antimony ore are used as the combination Collector, with 130g new pinol oil / t antimony sulfide as foaming agent; in the first sweep and second sweep, both with 40g lead nitrate / t antimony sulfide as activator, both with 60gMA -3 / t antimony sulfide ore is used as collector; in the third sweeping and beneficiation, no chemicals are added.

Embodiment 2

[0028] Crush the raw antimony sulfide ore until the particle size is less than 14mm, grind the ore until the particle size is 200 mesh, and the mass percentage of the sieve is 70.00%. and three times of beneficiation to obtain antimony concentrate; among them, in the rough selection, 80g lead nitrate / t antimony ore is used as the activator, and 130gMA-3 / t antimony ore and 110g ethyl disulfide / t antimony ore are used as the combination Collector, with 150g new pinol oil / t antimony sulfide as foaming agent; in the first sweep and second sweep, both with 50g lead nitrate / t antimony sulfide as activator, both with 65gMA -3 / t antimony sulfide ore is used as collector; in the third sweeping and beneficiation, no chemicals are added.

Embodiment 3

[0030]Crush the raw antimony sulfide ore until the particle size is less than 14mm, grind the ore until the particle size is 200 mesh, and the mass percentage of the sieve is 74.00%, add water and stir to make the slurry until the mass concentration of the slurry is 33.0%. and three times of beneficiation to obtain antimony concentrate; among them, in the rough selection, 65g lead nitrate / t antimony ore is used as the activator, and 110gMA-3 / t antimony ore and 90g ethyl disulfide / t antimony ore are used as the combination As a collector, 120g pine alcohol oil / t antimony ore is used as a foaming agent; in the first sweep and the second sweep, 35g lead nitrate / t antimony ore is used as an activator, both with 55gMA -3 / t antimony sulfide ore is used as collector; in the third sweeping and beneficiation, no chemicals are added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com