A kind of sulfide ore flotation composite collector and its preparation method and application

A composite collector, sulfide ore technology, applied in flotation, solid separation and other directions, can solve problems such as complex recovery and treatment process, achieve good economic prospects, reduce production costs, and solve environmental problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Preparation of collector:

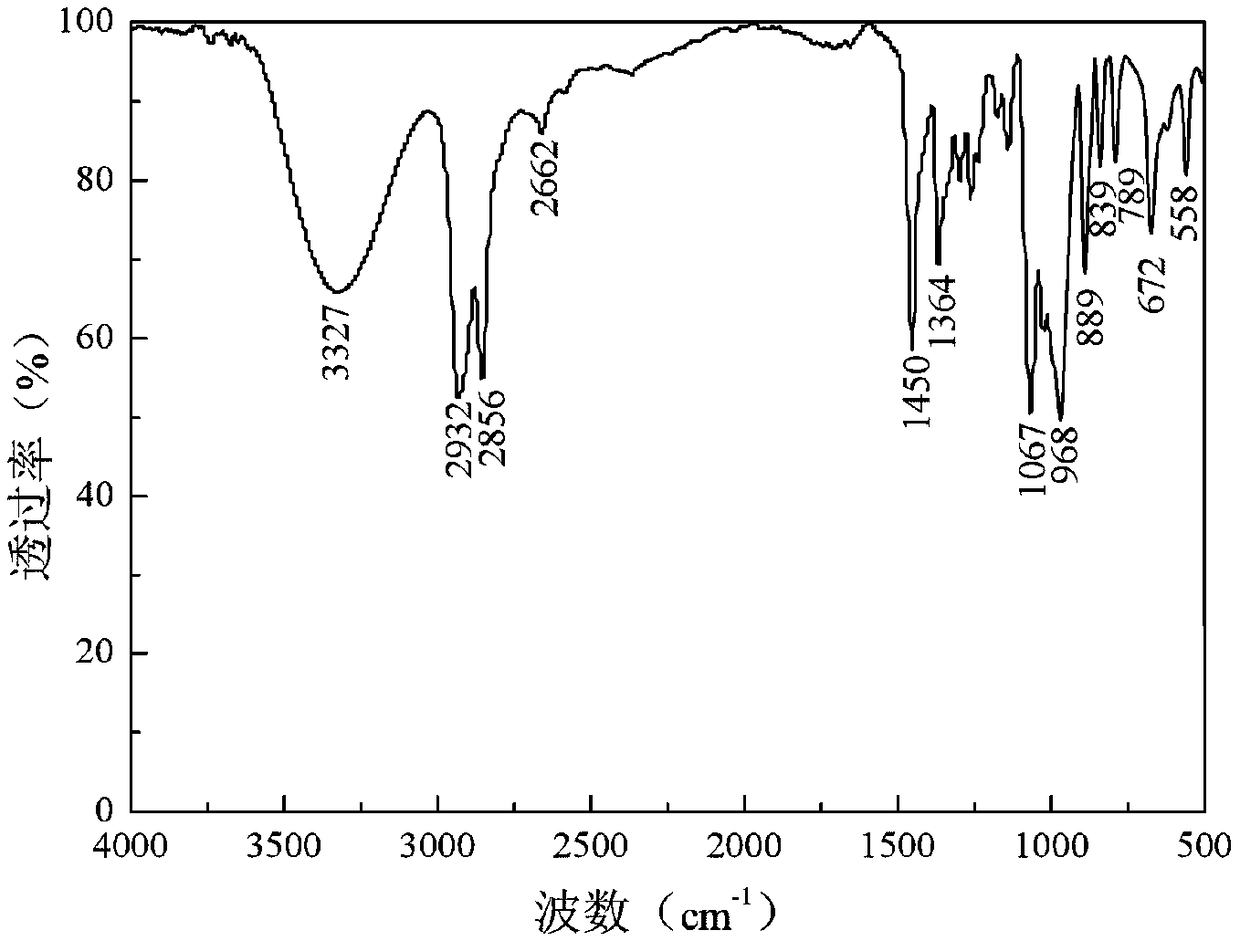

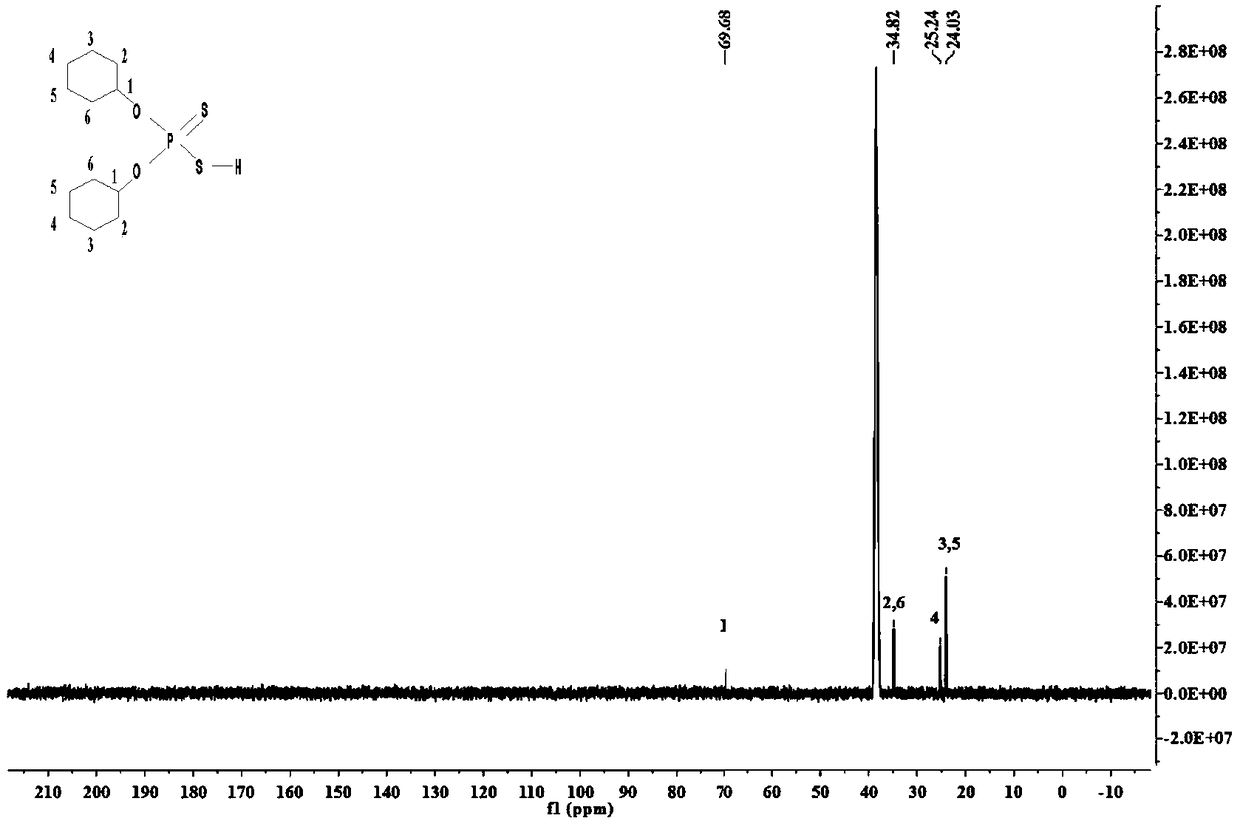

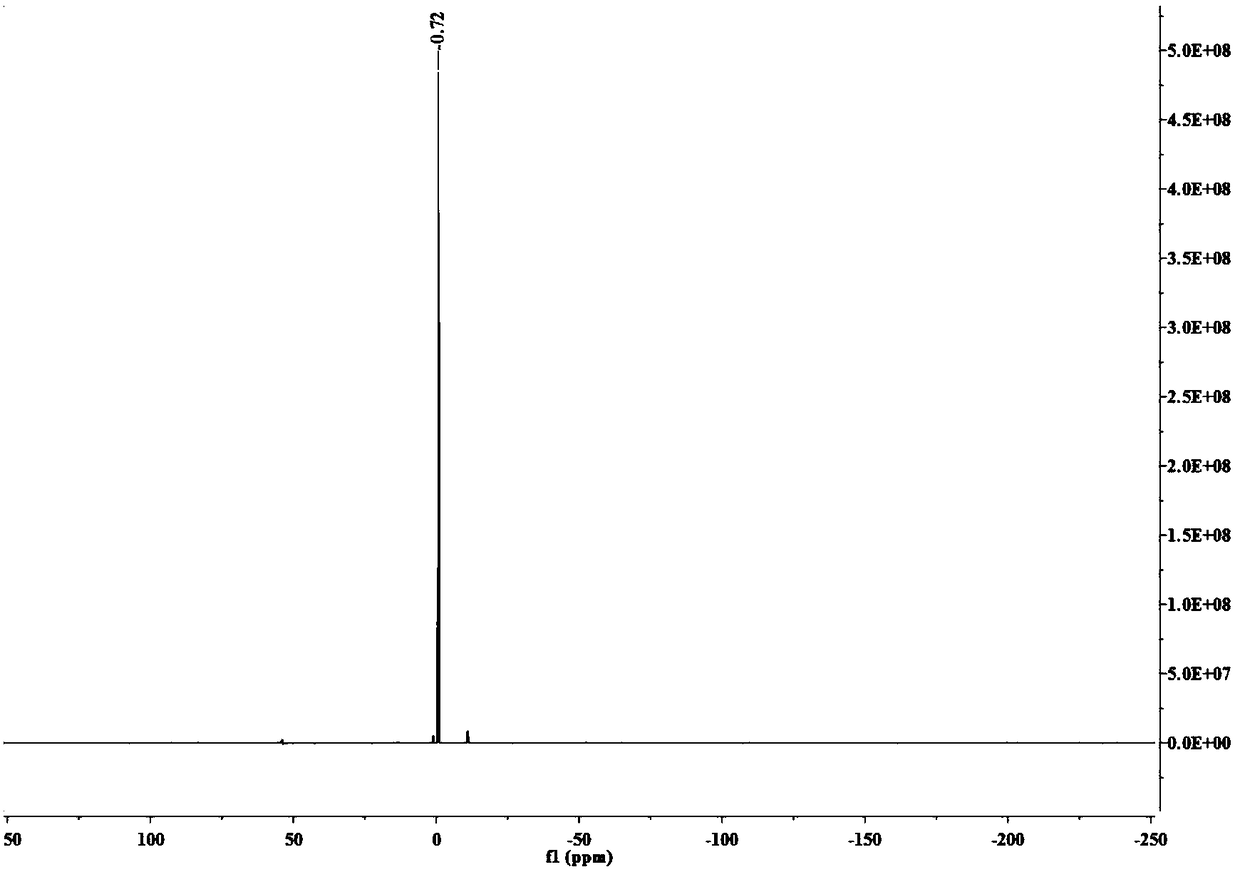

[0051]Add 200 parts of X oil and 153.3 parts of diesel oil into the reactor, and add 30 parts of phosphorus pentasulfide, and stir and react at 120°C for 2 hours to obtain a black oily liquid, which is the target collector product. After analysis and detection, the conversion rate of phosphorus pentasulfide is close to 100%, and the content of dihydrocarbyl dithiophosphoric acid in the collector product is 10.4%. The product was characterized after being separated and purified by silica gel chromatography, and the infrared spectrum of dicyclohexyl dithiophosphoric acid was as follows: figure 1 As shown, its main characteristic peaks are (cm -1 ): 2932, 2856 belongs to CH 2 The stretching vibration peak, 2662, 1450 is assigned to CH 2 Absorption peak; 1364 belongs to CH absorption peak; 1067 belongs to P-O-C, 968 belongs to P-O-CH 2 Absorption peak; 839 belongs to S-H absorption peak; 789,672 belongs to P=S absorption peak. dicyclohexyl d...

Embodiment 2

[0053] Preparation of collector:

[0054] Add 200 parts of X oil and 146.7 parts of diesel oil into the reactor, and add 20 parts of phosphorus pentasulfide, and stir and react at 110°C for 2 hours to obtain a black oily liquid, which is the target collector product. After analysis and detection, the conversion rate of phosphorus pentasulfide is close to 100%, and the content of dihydrocarbyl dithiophosphoric acid in the collector product is 7.2%.

Embodiment 3

[0056] Preparation of collector:

[0057] Add 200 parts of X oil and 90.2 parts of diesel oil into the reactor, and add 10.5 parts of phosphorus pentasulfide, and stir and react at 100°C for 2 hours to obtain a black oily liquid, which is the target collector product. After analysis and detection, the conversion rate of phosphorus pentasulfide is close to 100%, and the content of dihydrocarbyl dithiophosphoric acid in the collector product is 4.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com