Fast thread screw rod cleaning machine

A technology for cleaning machines and screw rods, applied in cleaning methods and tools, cleaning methods using tools, chemical instruments and methods, etc., can solve the problems of large usage, low efficiency, pollution of construction materials, etc., and achieve easy operation and improved The effect of work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

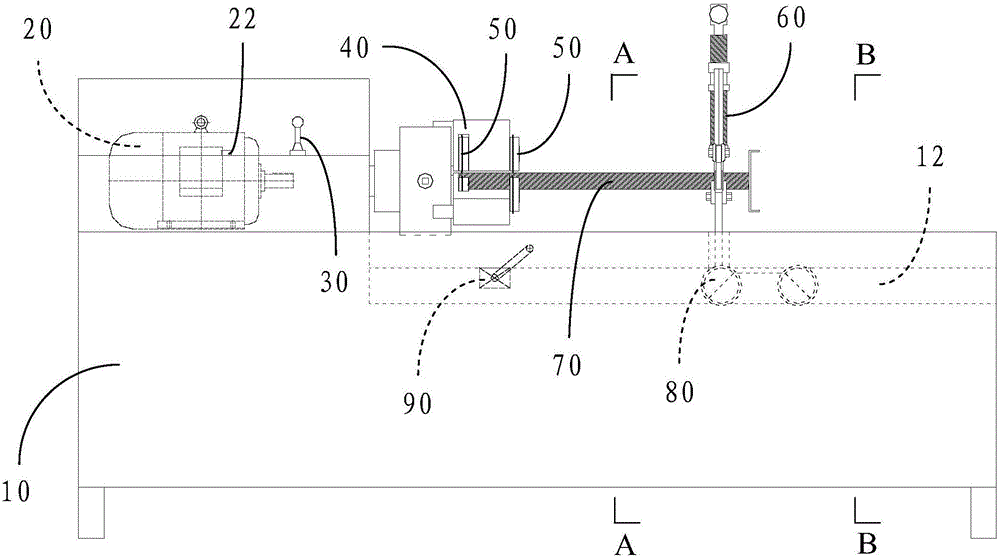

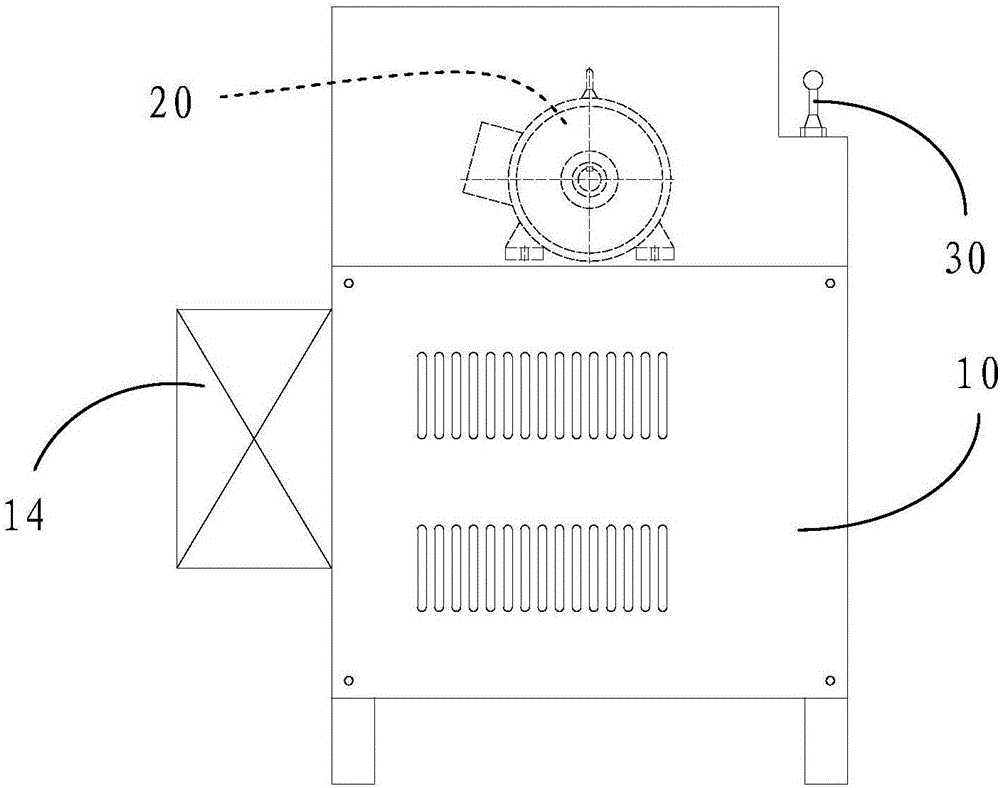

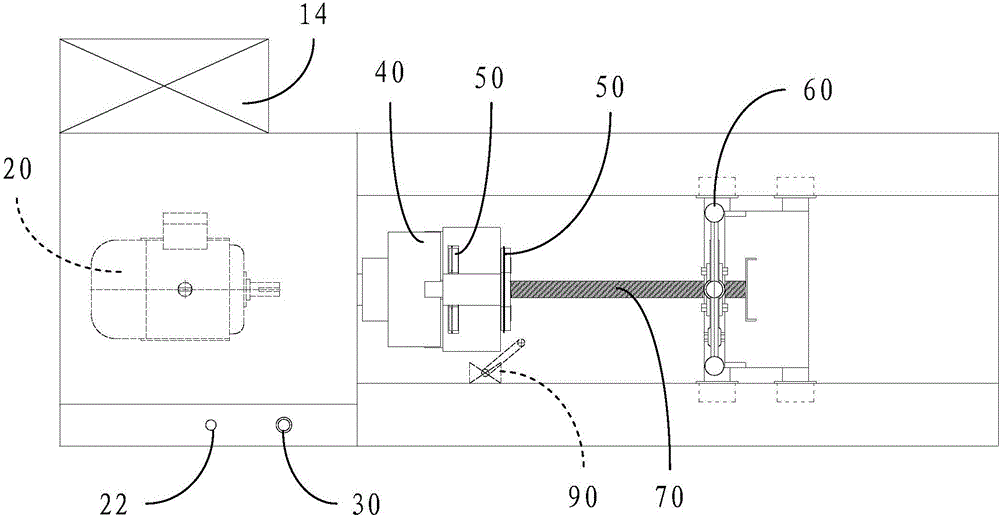

[0025] refer to figure 1 As shown, the threaded screw fast cleaning machine of the present invention includes: a frame 10, a roller device 80, a fastening device 60, a transmission shaft 40, and a cutter 50, and the frame 10 is provided with a frame track 12, preferably, The rack rail 12 is made of channel steel; preferably, the cutter 50 is a circular cutter. The roller device 80 is arranged on the frame track 12 and can move along the frame track 12; Figure 5 , the fastening device 60 is installed on the roller device 80, and can move along the frame track 12 along with the roller device 80; a transmission shaft 40 is also installed on the frame 10, and the position of the transmission shaft 40 needs to be set in accordance with the tightening The position of the fixing device 60 is matched, and at least one set of cutters is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com