Hydraulic system applied to hydraulic automatic molding machine

A hydraulic system and molding machine technology, which is applied to the parts of molding machines, molding machines, casting molding equipment, etc., can solve the problems of unstable operation of the machine, many required personnel, and slow molding speed, so as to improve molding accuracy, Improve molding speed and reduce temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The applicant of this patent takes the workshop of Nan'an Jiejia Hydraulic Machinery Co., Ltd. as the specific implementation location of the technical solution of this patent, and provides the following specific examples:

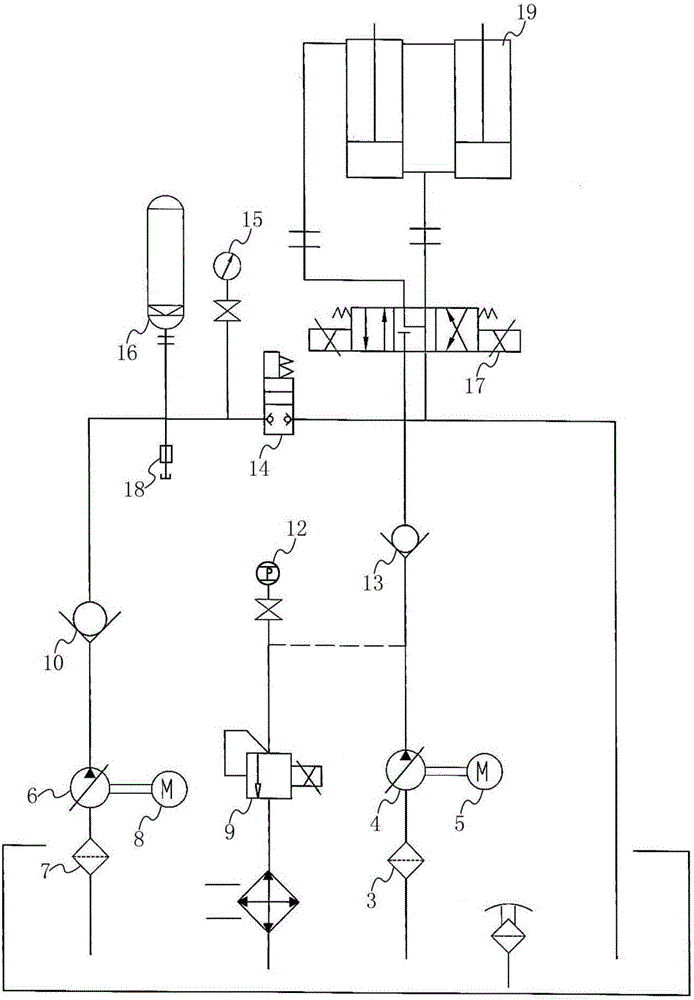

[0029] Such as figure 1 Shown, a kind of hydraulic system that is applied in the hydraulic automatic molding machine, it is made up of clamping oil cylinder 19, hydraulic oil tank, PQ pump, motor, one-way valve, water cooler, accumulator 16, fast oil drain valve 14 , a main pressure gauge 15, a pressure sensor 12, a proportional reversing valve 17, and an oil circuit block, characterized in that,

[0030] The first motor 5 is connected to the first PQ pump 4, the first PQ pump 4 is connected to the first one-way valve 13 through the first filter 3, the first one-way valve 13 is connected to the proportional reversing valve 17 through the oil pipe, the first The PQ pump 4 is provided with a proportional control valve 9 with a pressure sensor 12;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com