Pneumatic clamping general lathe

A common lathe, clamping technology, applied in the field of common lathes, can solve the problems of deformation of the workpiece, failure to master the strength of pulling the chuck S1, time-consuming and labor-intensive problems, and achieve the effect of reducing rigid impact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0040] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

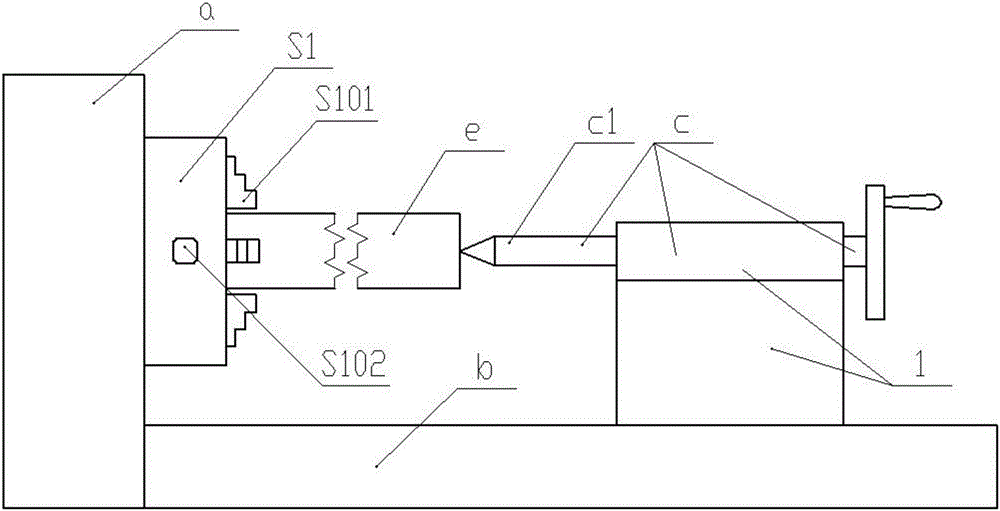

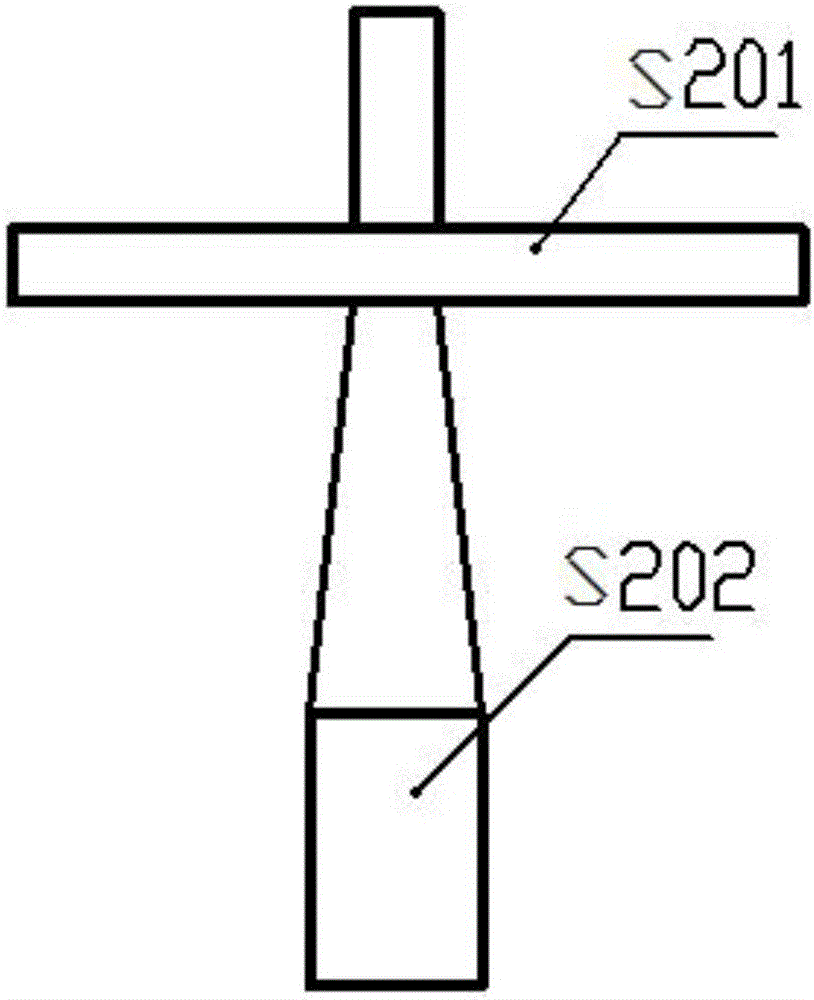

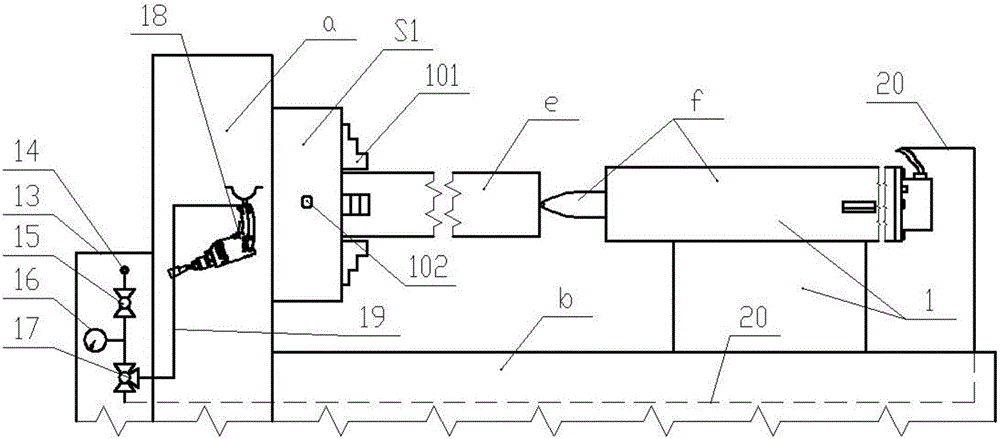

[0041] Such as image 3 As shown, a pneumatic clamping type ordinary lathe includes a headstock a and a chuck S1 connected to the main shaft in the headstock a, and a tailstock 1 with a top on the machine tool guide rail b; on the chuck S1 There is a wrench hole S10. What is different from existing common lathes is; also comprise pneumatic system 13, described pneumatic system 13 comprises cylinder, and the compressed gas output port 14 of cylinder is connected with three-way valve 17 through control valve 15, in described control valve 15 and three-way A precision gas pressure gauge 16 is provid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com