Process for processing high-accuracy phase difference of duplicate gear

A dual gear and processing technology, which is applied in metal processing equipment, gear tooth manufacturing devices, belts/chains/gears, etc., can solve problems such as inability to guarantee, and achieve the effect of improving relative accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

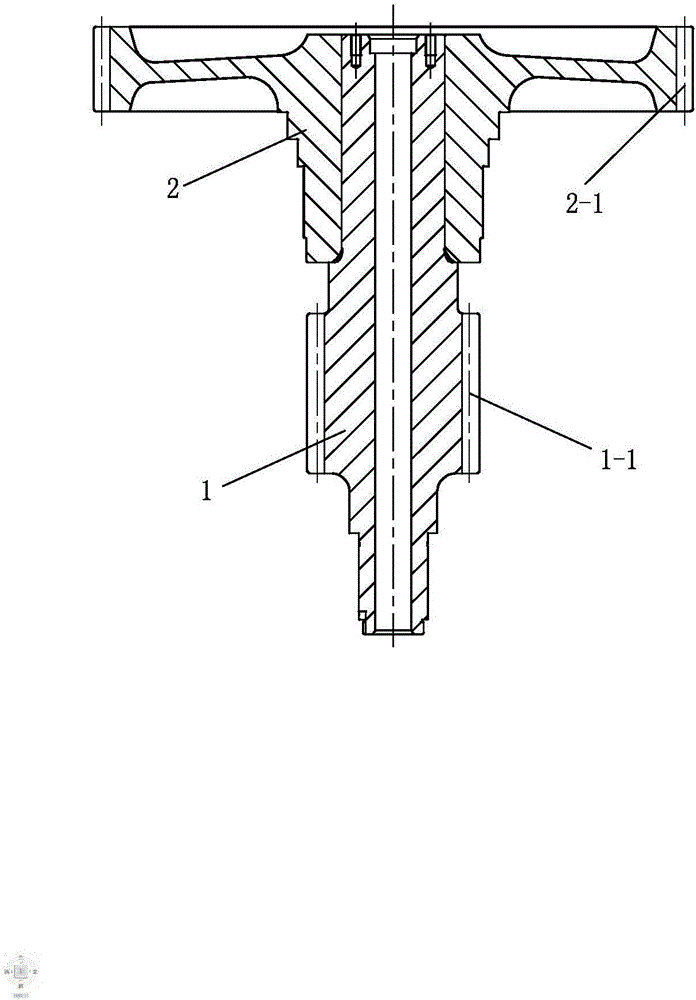

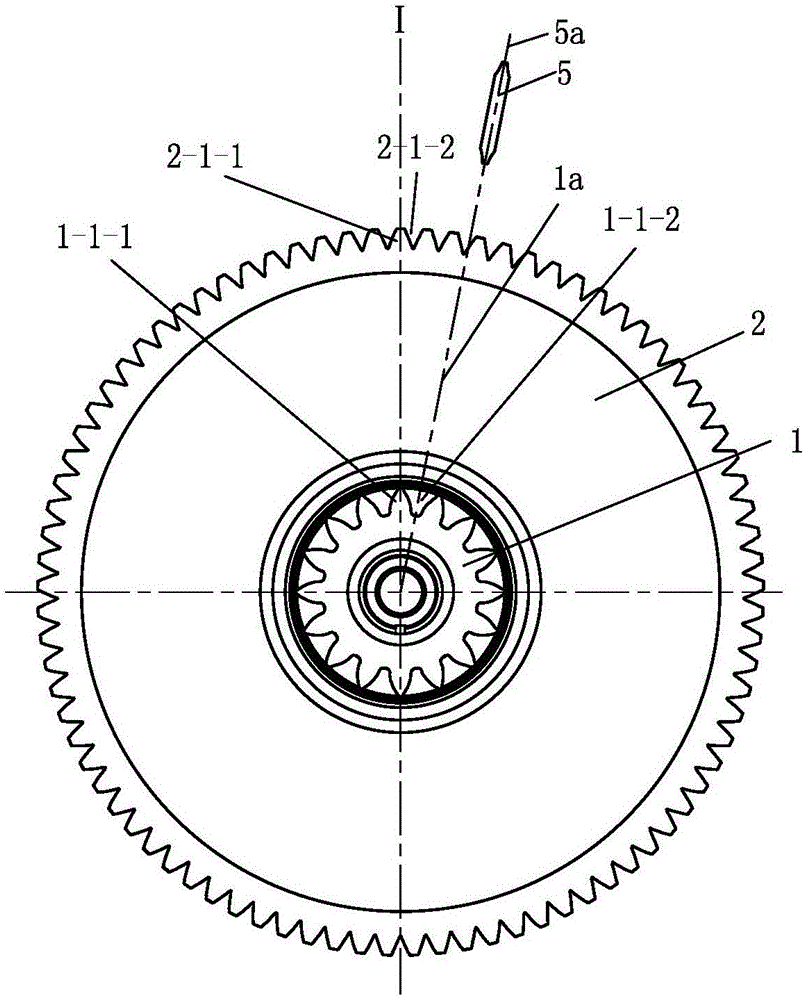

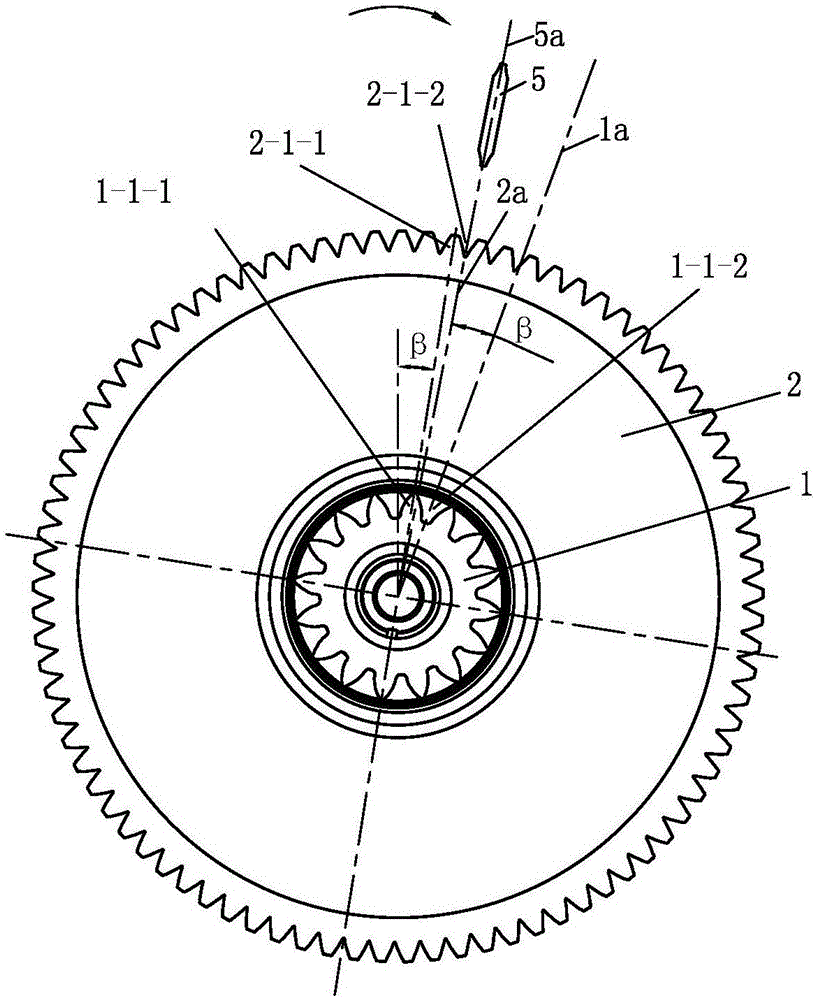

[0026] To complete the high-precision phase-difference processing technology of the dual gears in this embodiment, in addition to the usual gear grinding machine, a gear alignment tool 4 is also required. figure 1 That is the diagram of the double-connected gear, and the tooth-aligning tool 4 is a double-connected gear-aligning assembly tool provided by the invention patent of the Chinese patent application number CN201410286087.3.

[0027] See Figure 5 , the tooth tooling 4 includes a positioning cylinder 4-1 and a base 4-3, the positioning cylinder 4-1 has a cylinder bottom plate 4-1-1 and a cylinder body 4-1-2, the cylinder body 4-1-2 The upper end of the cylinder is open, the cavity of the cylinder body and the tooth portion 1-1 of the pinion are in clearance fit, and the cylinder body 4-1-2 is provided with two relative positioning holes, and each positioning hole is dynamically fitted with a lower top 4-2 , the cylinder bottom plate 4-1-1 is provided with a central hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com