Assembly device

A pairing and support seat technology, applied in auxiliary devices, household containers, applications, etc., can solve the problems of reduced service life of guide rails and screw motors, inconsistent gap between connecting pipes and products, increased equipment costs and processing costs, etc., to achieve Improve local stress conditions, simple structure, and reduce beam stiffness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

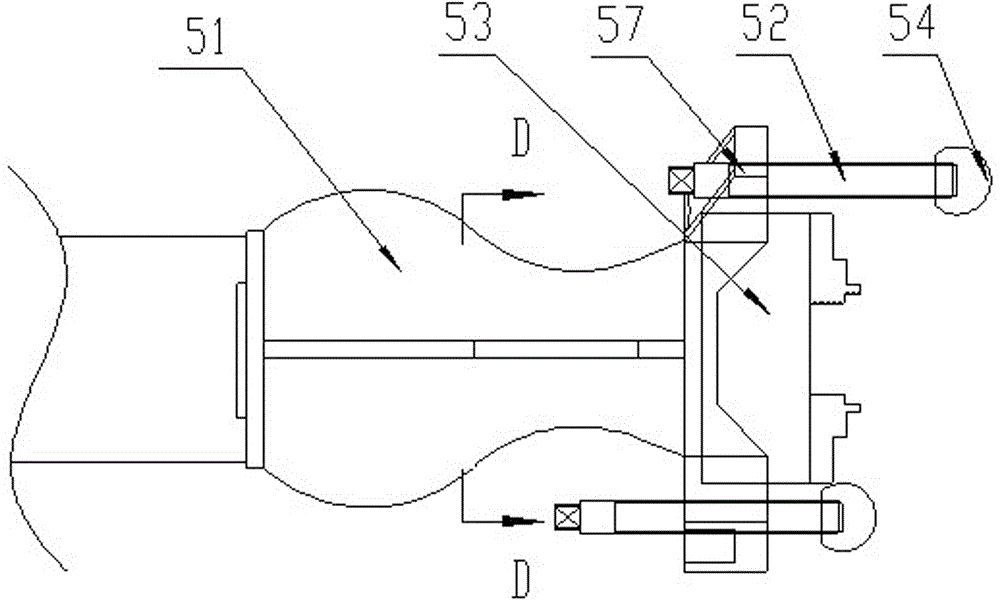

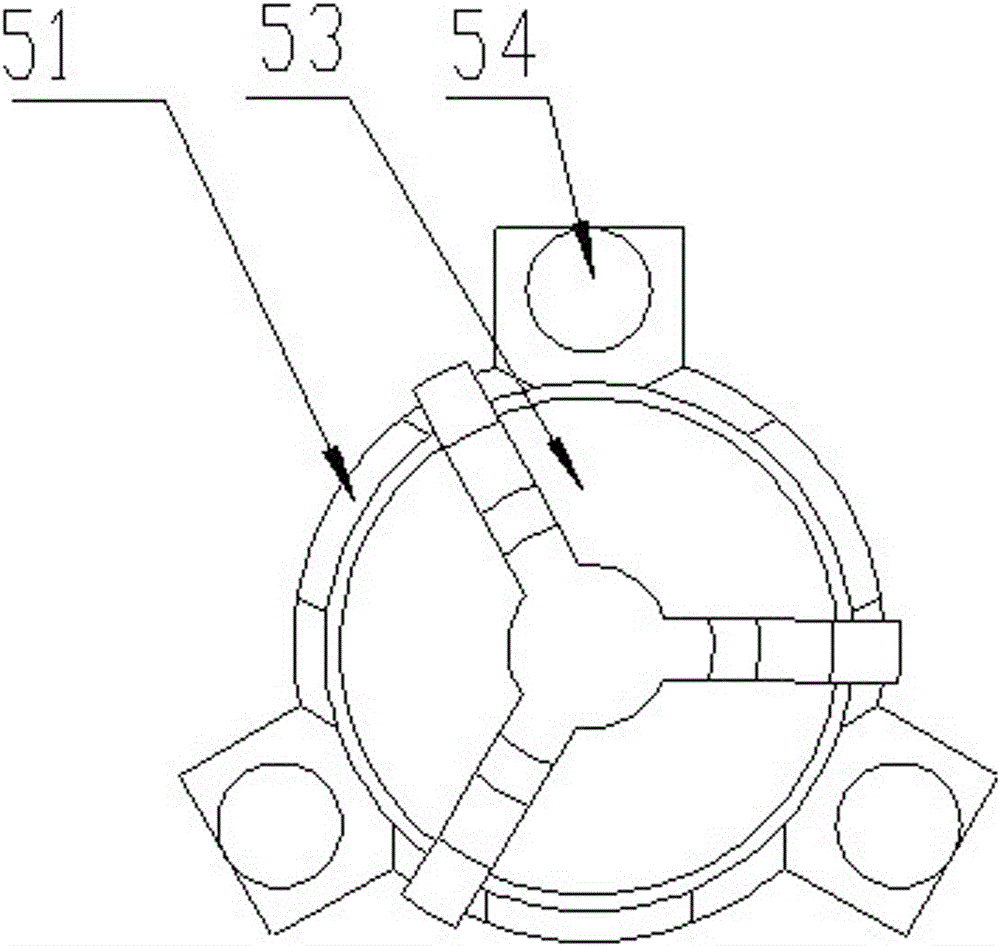

[0039] Example 1, such as figure 1 and figure 2 As shown, a pairing device, the pairing device includes a support base 51, the support base 51 consists of two parts, the two parts are crossed, and the stiffness of the crossed part will be lower than that of the beam part, even if the welding stress is not uniform during the pairing It cannot be completely offset by the set of pairing devices, and the deformation caused by the stress on the Z-axis can also be controlled at the cross position without causing damage to the connecting mechanism of the Z-axis and the Y-axis.

[0040] Each part includes a big end and a small end. The middle section is between the big end and the small end. The outer side of the big end protrudes outward, and the outer side of the middle section is concave inward. The width of the connecting end between the small end and the middle section is smaller than that of the small end. The width of the other end, the smooth transition of the outer surface ...

Embodiment 2

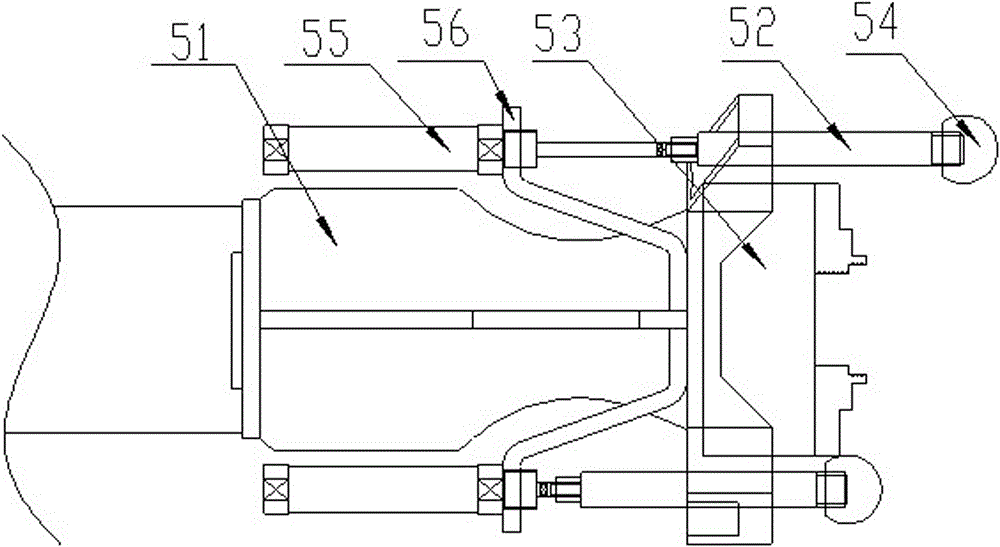

[0063] Example 2, such as image 3 As shown, a pairing device, the same as in the first embodiment will not be repeated in this embodiment, and only the differences from the first embodiment will be described in this embodiment.

[0064] Support seat 51 comprises two parts, and two parts are crossed, and each part comprises big end and small end, and middle section is between big end and small end, and the outer side of big end is straight line segment, and the outer side of middle section is concave inward, and the small end The width of the connecting end between the head end and the middle section is smaller than the width of the other end of the small head end.

[0065] A hydraulic mechanism is arranged on the supporting base 51, and the hydraulic mechanism includes a hydraulic cylinder 55, and the hydraulic cylinder 55 has a piston rod.

[0066] The end of the push rod 52 is connected with the piston rod of the hydraulic mechanism, and the hydraulic cylinder 55 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com