Automatic segment bolt tightening system of segment erector

A segment assembly and mechanical segment technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of fatigue in manual operation, lengthening the construction period of assembling segments, and uneven force distribution when connecting segments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

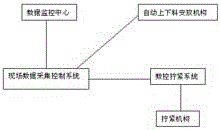

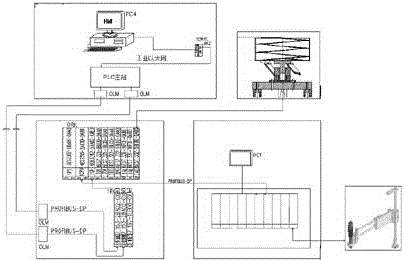

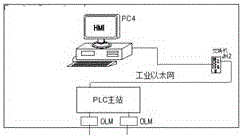

[0022] Such as figure 1 , 2 As shown, the present invention provides an automatic segment bolt tightening system for a segment assembly machine, which includes: a data monitoring center, an automatic loading and unloading mechanism, an on-site data acquisition control system, a segment bolt tightening numerical control system, and a segment bolt tightening system. The data monitoring center controls and monitors the data generated during the bolt tightening process, and records and warns of unqualified situations; into the designated segment connection hole; the on-site data acquisition control system realizes the on-site data acquisition through the programmable controller, and transmits the data to the data monitoring center through the bus; the segment bolt tightening numerical control system provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com