Anti-deformation machining method for thin-wall disc-shaped part

A processing method and technology of thin-walled discs, which are applied in metal processing equipment, metal processing machine parts, manufacturing tools, etc., can solve problems such as processing deformation of thin-walled disc parts, improve the quality of processed products, improve dimensional accuracy, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

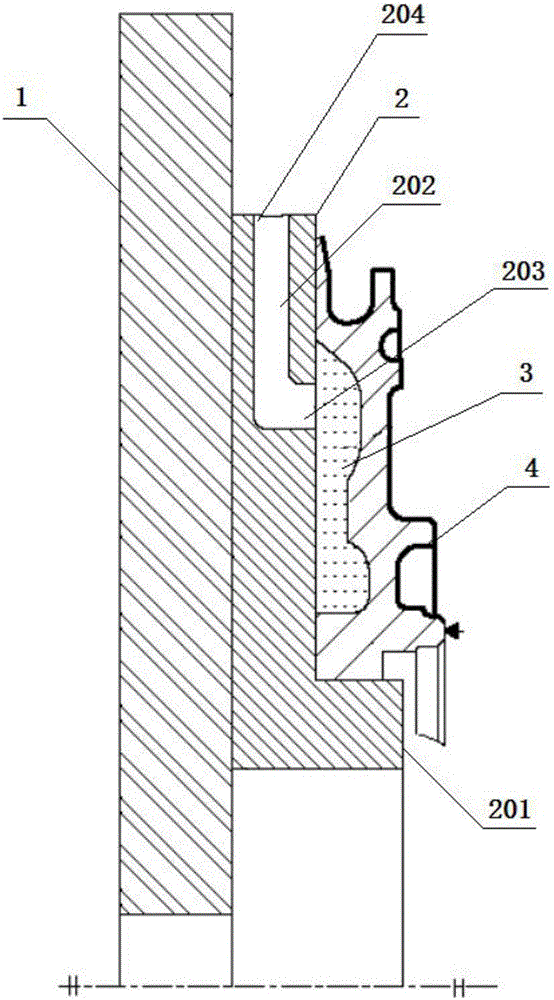

[0021] A processing method for anti-deformation of thin-walled disk parts, (1) design fixture: such as figure 1 As shown, the fixture is a flat piece, and there is a centering boss 201 on the upper surface of the fixture, which can stabilize the part to be processed and facilitate the smooth progress of processing. An "L"-shaped through hole 202 is opened on the side of the fixture. The other end of the hole is opened on the upper surface of the fixture, the orifice on the side is the inlet 204, and the orifice on the upper surface is the outlet 203, to ensure that after the part is loaded into the fixture, the outlet 203 is located inside the cavity of the part, and close to the center of the cavity; (2) Install the fixture: then install the related fixture on the faceplate of the CNC machine tool, and align the fixture; (3) Install the workpiece to be processed: clamp the workpiece to be processed on the fixture, and align it Workpiece to be processed; (4) pouring low-meltin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com