Towed integrated stirring and pumping machine

A technology of mixing pump and all-in-one machine, which is applied in the field of tow-type mixing and pumping all-in-one machine, can solve the problems of uncontrollable arrival time at the site, uncontrollable concrete setting time, uncontrollable transportation time, etc., and achieves a controllable mixing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

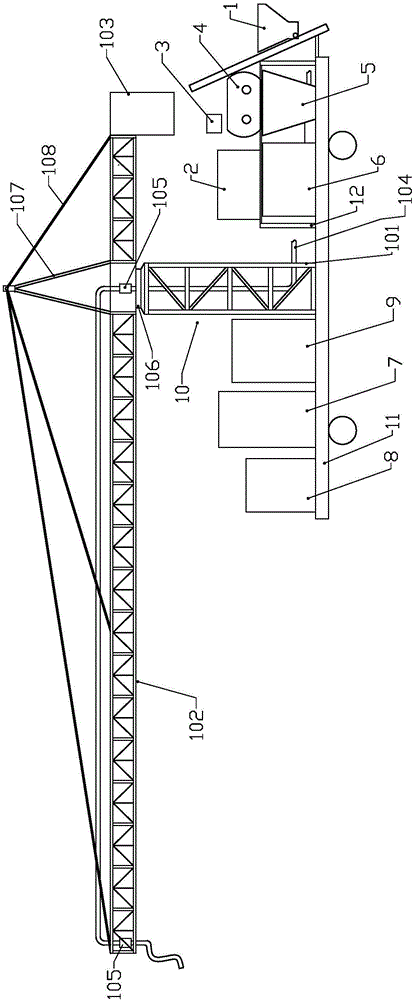

[0010] Refer to the attached figure 1 The drag-type mixing and pumping integrated machine of the present invention will be described in detail below.

[0011] The drag-type mixing and pumping integrated machine of the present invention has a structure comprising a hopper 1, a water storage tank 2, a metering water tank 3, a mixer 4, a material storage tank 5, a pumping machine 6, an additive storage tank 7, a generator set 8, and a console 9 and automatic pipeline control machine 10, the generator set 8, additive storage tank 7, console 9, automatic pipeline control machine 10, pumping machine 6, material storage box 5 and upper hopper 1 are arranged in sequence from left to right On the trailer 11, a frame 12 is arranged on the upper trailer 11 of the pumping machine 6 and the material storage box 5, and the water storage tank 2 and the mixer 4 are respectively located on the frame 12, and the The metering water tank 3 is located on the top of the mixer 4, the metering water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com