Integrated brake master cylinder

A brake master cylinder, integrated technology, applied in the direction of brakes, brake transmissions, transportation and packaging, etc., can solve the problems of increasing costs, increasing the working noise of vacuum pumps, and failing to meet the energy recovery function of energy vehicles. Improve energy recovery efficiency, fast and precise wheel cylinder pressure control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

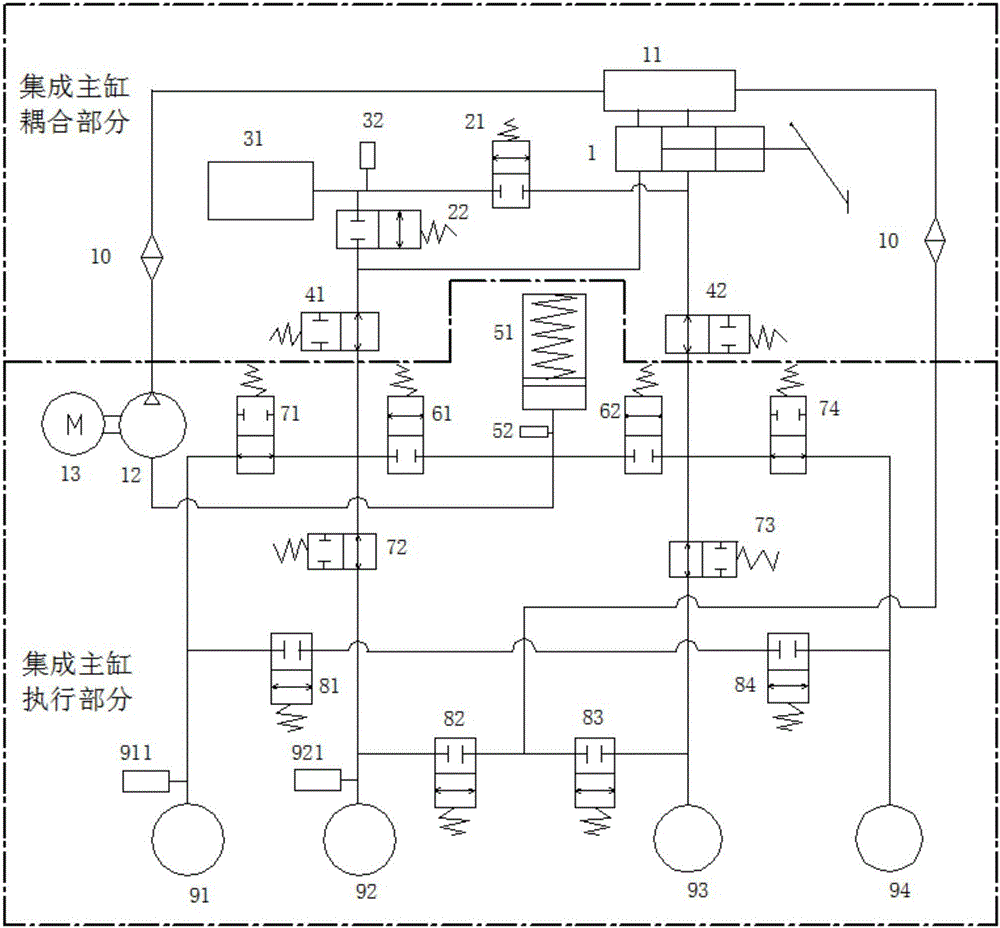

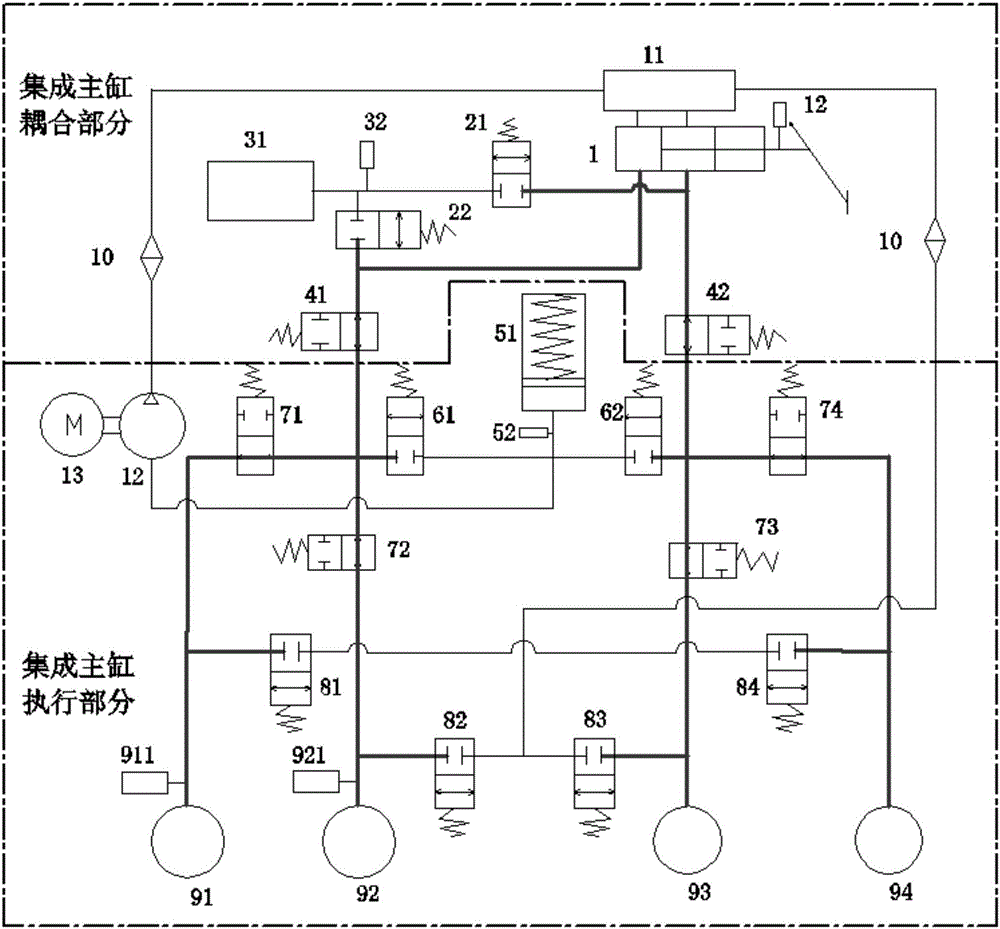

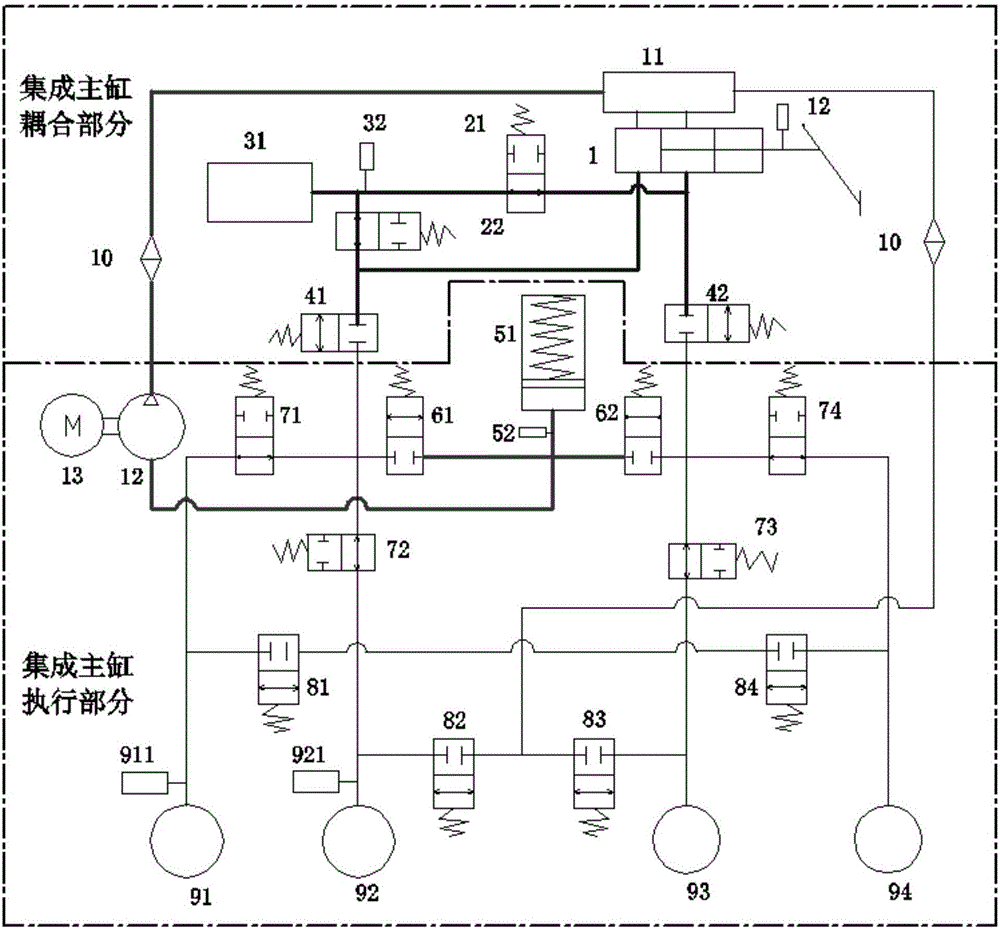

[0019] like figure 1 As shown, the integrated master cylinder includes two parts: the coupling part of the integrated master cylinder and the execution part of the integrated master cylinder. Among them, the integrated master cylinder coupling part includes the brake master cylinder 1, the stroke sensor 12 integrated on the brake master cylinder, the front chamber pedal simulator normally closed solenoid valve 21, the rear chamber pedal simulator normally closed solenoid valve 22, the pedal simulation Device 31 and pedal simulator sensor 32, front cavity pedal simulator normally open solenoid valve 41, rear cavity pedal simulator normally open solenoid valve 42. The stroke sensor 12 monitors the piston stroke of the brake master cylinder, and the pedal simulator sensor 32 is used to monitor the pressure of the pedal simulator 31 . The front brake oil circuit and the rear brake oil circuit respectively flow out from the front and rear chambers of the brake master cylinder 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com