Oily material storage tank inner floating disc

An inner floating plate and material technology, which is applied in the directions of container, packaging, transportation and packaging, can solve the problems of deformation of the floating plate, difficult installation and construction, tilting of the floating plate, etc., and achieves reduction of evaporation loss, simple manufacturing method, and easy installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

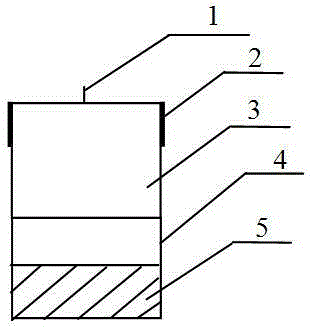

Embodiment 1

[0020] The float shell is made of plastic material, and the thickness of the plastic plate is 5mm; the upper part (light area, the same below) and the lower part (heavy area, the same below) of the float are both cubes of 300*300*200mm; the upper part is hollow; the lower part is filled with 15kg of concrete; The top is a circular sheet with a thickness of 1.5 mm and a diameter of 450 mm.

Embodiment 2

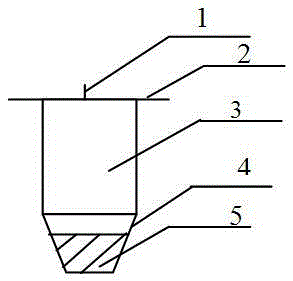

[0022] The float shell is made of 3mm aluminum plate, the upper part is a cube of 400*400*400mm, the lower part is a square pyramid of 400*400*100mm, the upper part is filled with foam plastic, and the lower part is filled with 27kg aluminum block; the top is a circular sheet with a thickness of 1mm and a diameter of 600mm. The upper part of the outer layer is wrapped with a layer of nitrile rubber with a thickness of 3mm and a wrapping height of 100mm.

Embodiment 3

[0024] The float shell is made of stainless steel plate with a thickness of 2mm. The upper and lower parts are cylinders with a diameter of 500mm and a height of 250mm. The upper part is hollow, and the lower part is filled with 38kg iron blocks and fixed at the bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com