Belt conveyor logistics quantity monitoring system

A flow monitoring and belt conveyor technology, applied in conveyor objects, conveyor control devices, conveyors, etc., can solve the problems of low practical application rate, inconvenient maintenance, high cost, and achieve strong anti-interference ability and reliability. High, ensure the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

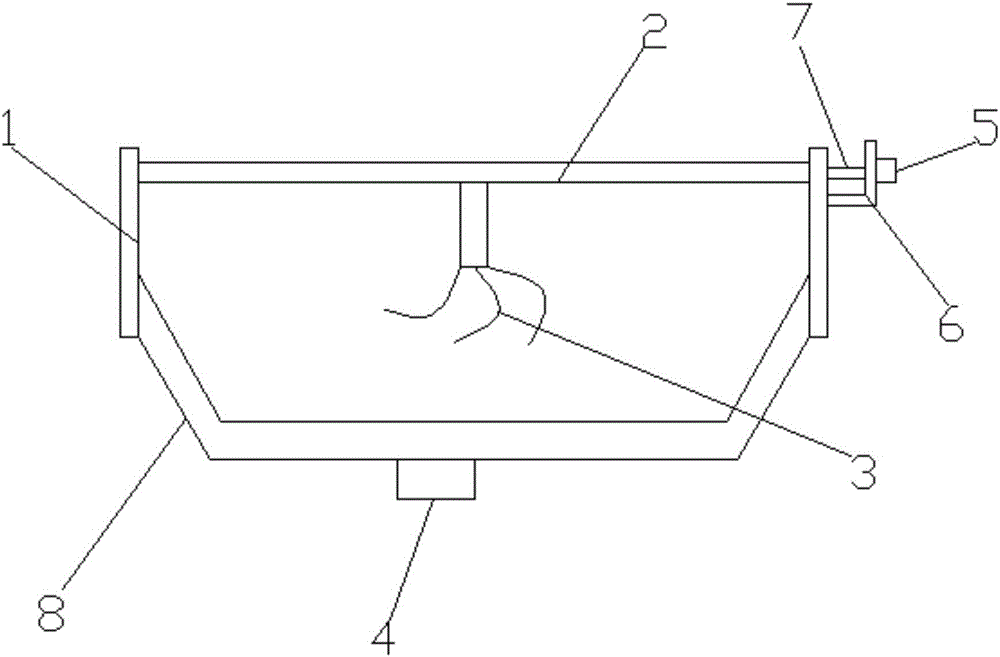

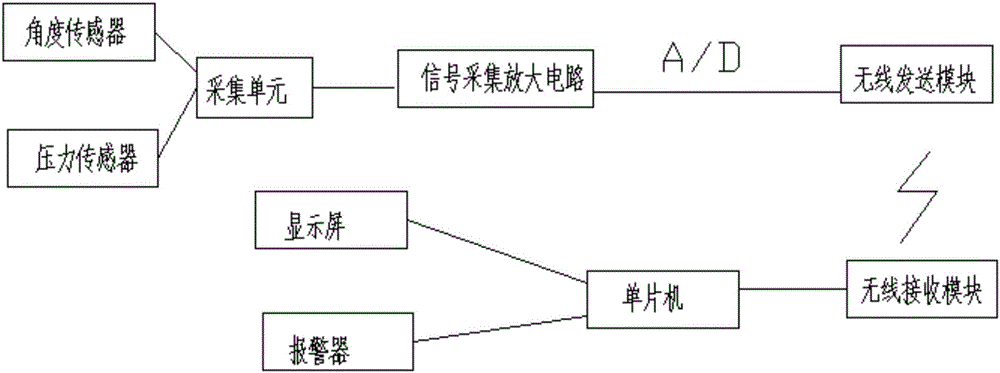

[0012] Such as figure 1 , figure 2 As shown, a belt conveyor material flow monitoring system provided by the present invention includes fixing bases 1 installed on both sides of the belt conveyor 8. The fixing bases are connected by a rotating shaft 2, and the center of the rotating shaft is perpendicular to the conveyor belt of the belt conveyor. However, a material thinning rake 3 is provided at a position that does not touch the conveyor belt. The material thinning rake is made of rubber material, and the number of claws at the end is greater than three. The system also includes a collection unit, a data transmission unit, a single-chip computer, and the display and alarm of the LCD control room. The collection unit is connected to the wireless sending module in the data transmission unit, and the wireless receiving module in the data transmission unit is connected to the input terminal of the single-chip computer. Connect, the output terminals of the single-chip microcompu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com