Crane trolley adopting hydraulic lifter for lifting loads

A hydraulic lifting and crane technology, applied in the direction of load block, load hanging components, traveling mechanism, etc., can solve the problems of long-term inspection and maintenance, low frequency of use, complex structure, etc., achieve convenient disassembly and maintenance, and save costs , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

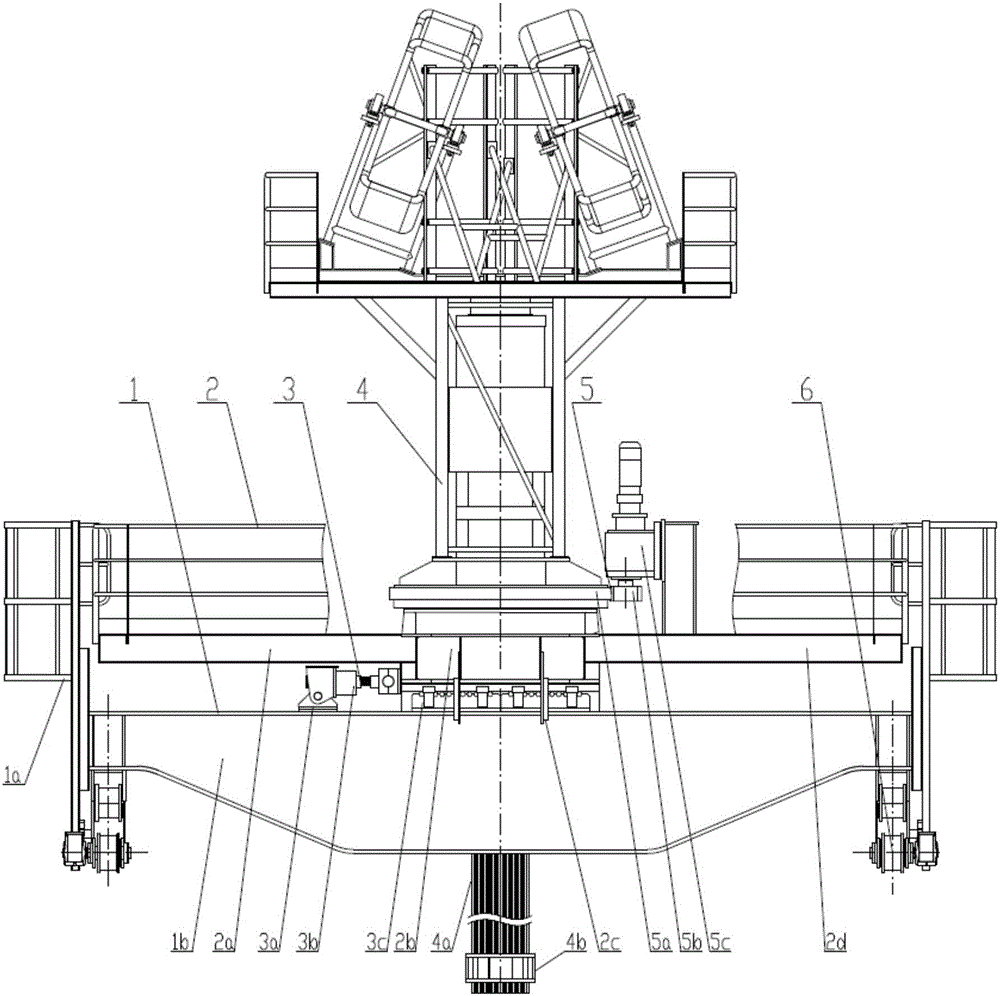

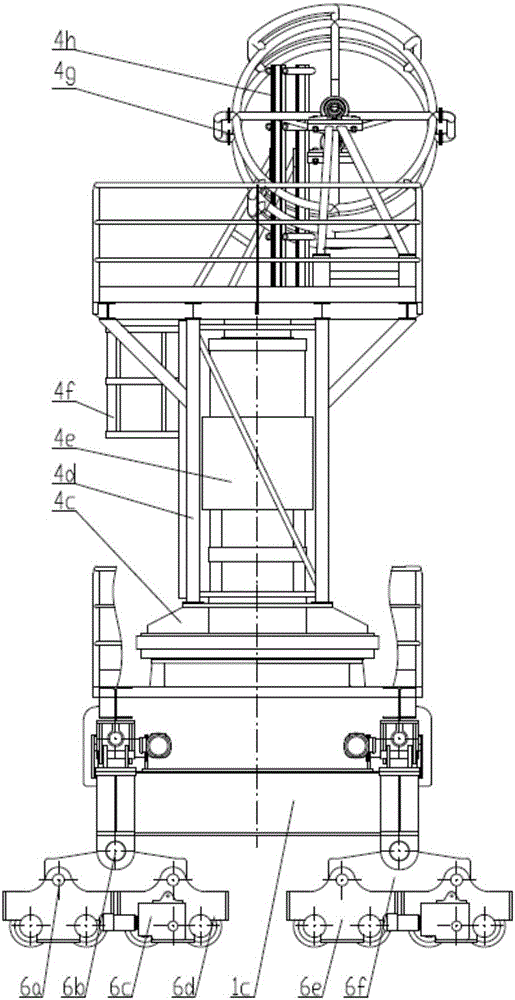

[0040] Such as figure 1 and figure 2 The shown crane trolley adopts a hydraulic hoist to lift loads, including: a lower frame 1, an upper frame 2, a translation mechanism 3, a lifting mechanism 4, a rotation mechanism 5 and an operating mechanism 6;

[0041] The running mechanism 6 drives the trolley to reciprocate along the direction of the track, and the running mechanism 6 is installed at both ends of the lower frame 1;

[0042] The translation mechanism 3 is arranged in the upper middle area of the lower frame 1, and the translation mechanism 3 carries the upper frame 2, the lifting mechanism 4 and the rotation mechanism 5;

[0043] The rotating mechanism 5 is arranged between the upper frame 2 and the lifting mechanism 4 and fixed on the upper frame 2;

[0044] The lifting mechanism 4 is fixed on the rotating mechanism 5, and the rotating mechanism 5 can drive the lifting mechanism 4 to rotate 360 degrees;

[0045] The lower frame 1 includes: a boarding ladder 1a,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com