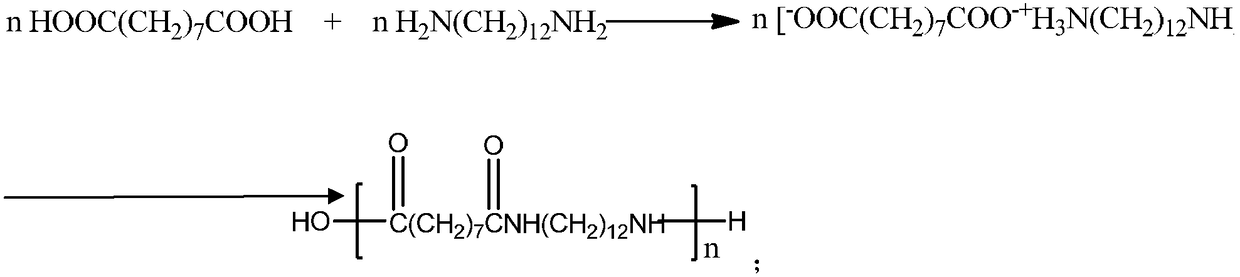

A kind of bio-based long carbon chain polyamide and its synthesis method

A carbon chain polyamide and a synthesis method technology are applied in the fields of bio-based polyazelaic acid acyl dodecanediamide and its synthesis, bio-based long carbon chain polyamide and its synthesis, and can solve the problem of polymer molecular weight and performance degradation, The operation steps and technological processes are complicated, and the difficulty of post-processing work is increased, so as to reduce the loss of reaction monomers, alleviate the increasing depletion of fossil resources, and reduce the cost and equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A synthetic method of bio-based long carbon chain polyamide, comprising the following steps:

[0037] Mix the monomer 1,12-dodecanediamine and 1,9-azelaic acid, according to the reaction monomer (that is, the sum of the mass of 1,9-azelaic acid and 1,12-dodecanediamine) and The mass ratio of deionized water is 1:0.1, add deionized water, and stir at a speed of 500r / min for 1 minute.

[0038] Add the above mixed system into the polymerization kettle through the feeding port of the polymerization kettle, the monomer molar ratio of 1,9-azelaic acid and 1,12-dodecanediamine is 1:1.004, seal the polymerization kettle; then polymerize The atmosphere in the kettle is replaced by a nitrogen atmosphere, and the method of replacing the atmosphere in the polymerization kettle with a nitrogen atmosphere is to vacuumize the closed polymerization kettle for 1 minute, then pass in and discharge an inert gas for 8 minutes, and then under stirring, the above-mentioned mixing The system...

Embodiment 2

[0041] A synthetic method of bio-based long carbon chain polyamide, comprising the following steps:

[0042] Mix the monomer 1,12-dodecanediamine with 1,9-azenedioic acid, according to the reaction monomer (that is, the sum of the mass of 1,9-azelaic acid and 1,12-dodecanediamine) and The mass ratio of deionized water is 1:0.9. Add deionized water and stir at a speed of 200r / min for 10 minutes.

[0043] Add the above mixed system into the polymerization kettle through the feeding port of the polymerization kettle, the monomer molar ratio of 1,9-azelaic acid and 1,12-dodecanediamine is 1:1.005, seal the polymerization kettle; then polymerize The atmosphere in the kettle is replaced by a nitrogen atmosphere, and the method of replacing the atmosphere in the polymerization kettle with a nitrogen atmosphere is to vacuumize the closed polymerization kettle for 10 minutes, then feed and discharge an inert gas for 1 minute, and then, under stirring, the above-mentioned mixing The sy...

Embodiment 3

[0046] A synthetic method of bio-based long carbon chain polyamide, comprising the following steps:

[0047] Mix the monomer 1,12-dodecanediamine and 1,9-azelaic acid, according to the reaction monomer (that is, the sum of the mass of 1,9-azelaic acid and 1,12-dodecanediamine) and The mass ratio of deionized water is 1:0.6. Add deionized water and stir at a speed of 300r / min for 5 minutes.

[0048] Add the above mixed system into the polymerization kettle through the feeding port of the polymerization kettle, the monomer molar ratio of 1,9-azelaic acid and 1,12-dodecanediamine is 1:1, seal the polymerization kettle; then polymerize The atmosphere in the kettle is replaced by a nitrogen atmosphere, and the method of replacing the atmosphere in the polymerization kettle with a nitrogen atmosphere is to vacuumize the closed polymerization kettle for 5 minutes, then feed and discharge an inert gas for 6 minutes, and then, under stirring, the above-mentioned mixing The system unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com