Styrene-butadiene-rubber ultraviolet-resistant PE (Polyethylene) foaming board material and preparation method thereof

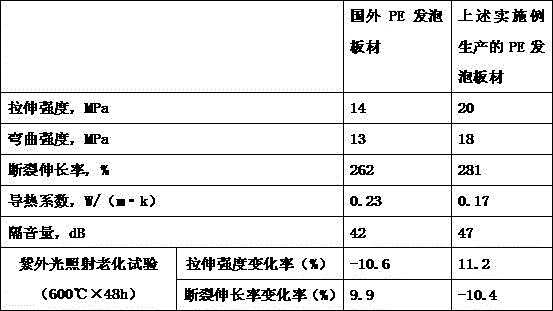

A technology of styrene-butadiene rubber and foamed sheet, which is applied to the field of PE foamed sheet and its preparation, can solve the problems of gap, the improvement of thermal insulation performance and sound absorption and sound insulation performance of composite materials is not obvious, and achieves the improvement of thermal insulation performance. , Improve mechanical properties and thermal stability, good UV resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A styrene-butadiene rubber anti-ultraviolet PE foam sheet, made of raw materials of the following weight (kg): low-density polyethylene 72, acrylic rubber 41, chlorinated polyethylene 34, dimethoxyethyl phthalate 17. Bis-tert-butyl peroxycumene 3, Triallyl isocyanurate 2, Diethylhexyloxyphenol methoxyphenyl triazine 2 Silica 6, Loofah 20, Bauxite 3.5, paraffin oil 12, glycerin 6, bamboo chips 38, nano titanium dioxide 7, nano kaolinite 21, styrene-butadiene rubber 42, zinc p-toluene sulfinate 6, pearl stone 8, homosalate 7, magnesium methacrylate 4.

[0021] A preparation method of styrene-butadiene rubber anti-ultraviolet PE foam plate, comprising the following steps:

[0022] (1) Mix bamboo chips, styrene-butadiene rubber, and loofah evenly, dry to constant weight, cut, grind, pulverize, and sieve; then add the sieved powder to the In a sodium hydroxide solution with a molar concentration of 2mol / L, heat the oil bath to 110-120°C, ball mill at a speed of 5000-7000r / ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap