Fluorinated polysiloxane nanometer anticorrosive engineering paint and preparation method thereof

A nano-engineering technology, which is applied in the field of fluorine-silicon nano-anti-corrosion engineering paint and its preparation, can solve the problems of poor wear resistance, short anti-corrosion period, and poor high-temperature resistance, and achieve good wear resistance, high-temperature resistance, and anti-corrosion long term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

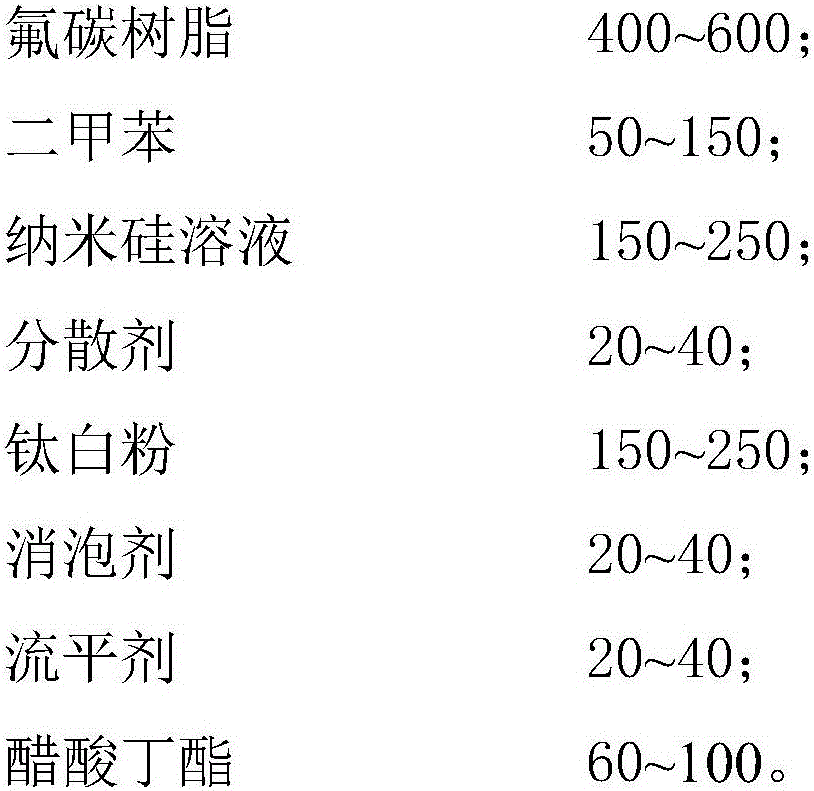

Method used

Image

Examples

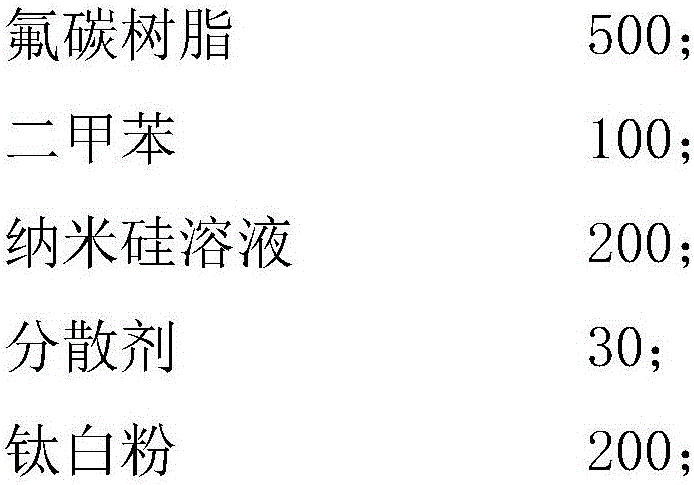

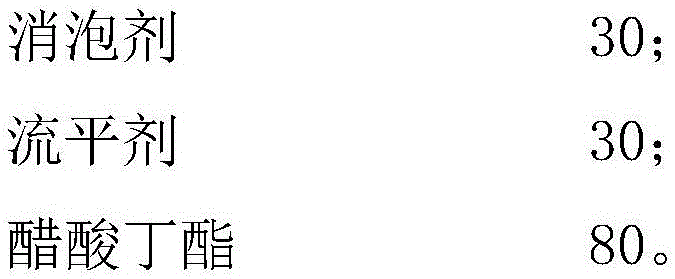

Embodiment 1

[0039] A method for preparing the fluorosilicon nano-anticorrosion engineering paint, comprising the steps of:

[0040] 1) Add 500g of fluorocarbon resin and 100g of xylene into the jacketed cylinder, and stir evenly;

[0041] 2) Heat the liquid in the tank to 50°C, then add 200g of nano-silicon solution while stirring, stir at a medium speed, keep the temperature at 60°C, stir for 35 minutes, then cool to 28°C;

[0042] 3) Add 30g of dispersant, stir evenly, add 200g of titanium dioxide while stirring, and disperse at high speed for 25min;

[0043] 4) Add 30g of defoamer, 30g of leveling agent, and 80g of butyl acetate, and stir at a medium speed for 25 minutes to obtain the fluorosilicon nano-anticorrosion engineering paint.

[0044] The medium-speed stirring speed in the step 2) and step 4) is 500r / min.

[0045] The dispersant in the step 3) is polyethylene wax.

[0046] The high-speed stirring speed in the step 3) is 1600r / min.

[0047] The defoamer is a mixture of emu...

Embodiment 2

[0051] A method for preparing the fluorosilicon nano-anticorrosion engineering paint, comprising the steps of:

[0052] 1) Add 400 parts by weight of fluorocarbon resin and 50 parts by weight of xylene in the jacketed cylinder, and stir evenly;

[0053] 2) Warm up the liquid in the tank to 50°C, then add 150 parts by weight of nano-silicon solution while stirring, stir at a medium speed, keep the temperature at 50°C, stir for 20 minutes, then cool to 20°C;

[0054] 3) Add 20 parts by weight of dispersant, stir evenly, add 150 parts by weight of titanium dioxide while stirring, and disperse at high speed for 20 minutes;

[0055] 4) Add 20 parts by weight of defoamer, 20 parts by weight of leveling agent, and 60 parts by weight of butyl acetate, and stir at a medium speed for 20 minutes to obtain the fluorosilicon nano-anticorrosion engineering paint.

[0056] The medium-speed stirring speed in the step 2) and step 4) is 550r / min.

[0057] The dispersant in the step 3) is one ...

Embodiment 3

[0063] A method for preparing the fluorosilicon nano-anticorrosion engineering paint, comprising the steps of:

[0064]1) Add 500 parts by weight of fluorocarbon resin and 100 parts by weight of xylene in the jacketed cylinder, and stir evenly;

[0065] 2) The temperature of the liquid in the tank is raised to 550°C, and then 200 parts by weight of nano-silicon solution is added while stirring, stirring at a medium speed, keeping the temperature at 55°C, stirring for 30 minutes, and cooling to 25°C;

[0066] 3) Add 30 parts by weight of dispersant, stir evenly, add 200 parts by weight of titanium dioxide while stirring, and disperse at high speed for 25 minutes;

[0067] 4) Add 30 parts by weight of defoamer, 30 parts by weight of leveling agent, and 80 parts by weight of butyl acetate, and stir at a medium speed for 20-30 minutes to obtain the fluorosilicon nano-anticorrosion engineering paint.

[0068] The medium-speed stirring speed in the step 2) and step 4) is 600r / min. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com