A kind of stepped air bundle air distribution plate of circulating fluidized bed gasifier

A technology of circulating fluidized bed and air distribution plate, which is applied in gasification process, granular/powdered fuel gasification, petroleum industry, etc. It can solve problems such as ash leakage and air chamber blockage, and achieve long service life and concentrated airflow , well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

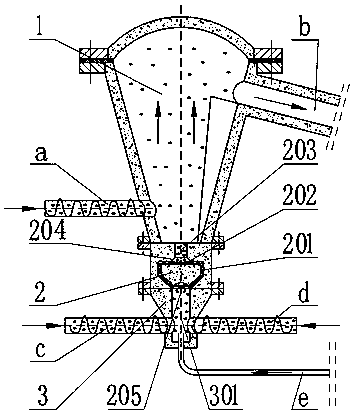

[0016] as attached figure 1 What is shown is the situation that the present invention is applied in a special-shaped internal circulating fluidized bed gasifier. The pulverized coal delivery pipe c and the carbon-containing fly ash delivery pipe d provided in the middle of the gas mixture chamber 301 deliver the pulverized coal and carbon-containing fly ash to Into the mixed gas chamber 301, the bottom of the mixed gas chamber 301 is provided with a gasification agent conduit e to send the gasification agent into the mixed gas chamber 301, and the pulverized coal and carbon-containing fly ash meet the gasification agent in the mixed gas chamber 301 and burn and gasify , the gasification agent in the gas mixture chamber 301 and the coal gas with high-temperature fly ash produced by combustion enter from the lower end of the vent hole 201 to the upper end of the vent hole 201, and then enter the gas material mixture through hole 203 and rush toward gasification Furnace 1 cavity....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com