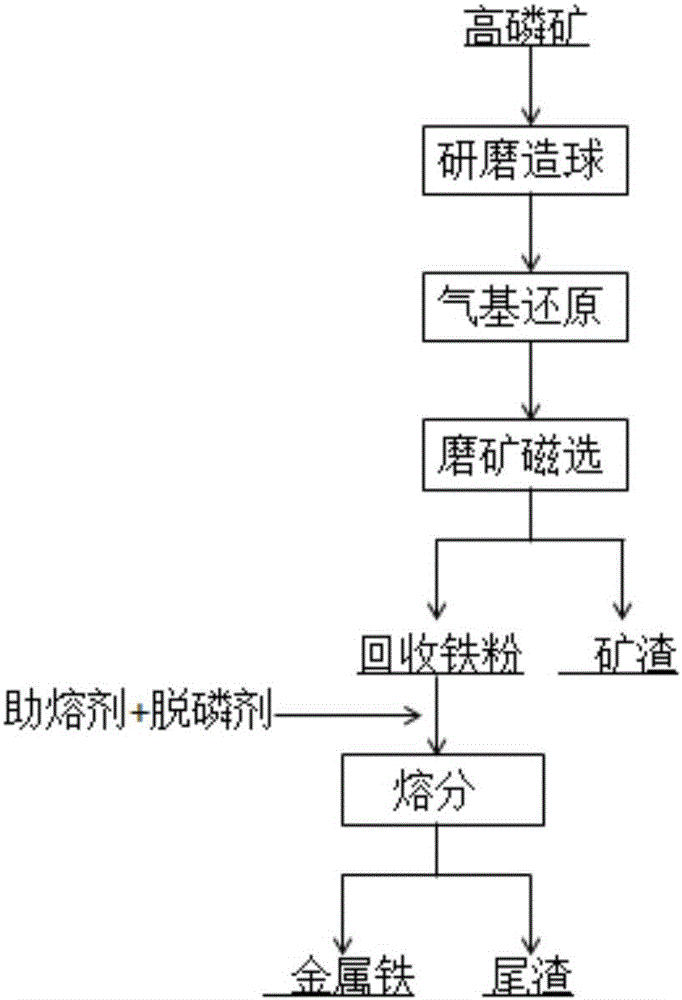

Pellet-reducing dephosphorizing method for high-phosphorus ore

A high-phosphorus ore and pellet technology, applied in the field of ironmaking, can solve problems such as difficult and impossible dephosphorization, and achieve effective dephosphorization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, oolitic high-phosphorus hematite is selected, the mass content of iron is 47.82%, and the content of phosphorus is 0.93 wt%. The oolitic high-phosphorus hematite was made into pellets and reduced under a reducing gas atmosphere at a temperature of 900°C. Among them, H 2 The volume of CO and CO accounted for 90% of the total volume of reducing gas, H 2 : CO = 2: 1, the reduction time was 4 hours, and the metallized pellets with a metallization rate of 90.94% were obtained.

[0035] The metallized pellets are finely ground on a ball mill, and the mass of the obtained metal particles with a particle diameter of ≤74 μm accounts for 93% of the total mass of the metal particles. Put the metal particles on a magnetic separator with a magnetic field strength of 1800Oe, the mass content of iron in the obtained recovered iron powder is 81%, and the recovery rate of metallic iron is 92%.

[0036] Add 3.5wt% CaO and 8wt% CaCl to recycled iron powder 2 As a f...

Embodiment 2

[0038] In this embodiment, oolitic high-phosphorus hematite is selected, the mass content of iron is 46.12%, and the content of phosphorus is 0.98 wt%. The oolitic high-phosphorus hematite was made into pellets and reduced under a reducing gas atmosphere at a temperature of 1000°C. Among them, H 2 The volume of CO and CO accounted for 95% of the total volume of reducing gas, H 2 : CO=2.5:1, the reduction time was 4.5h, and the metallized pellets with a metallization rate of 90.1% were obtained.

[0039] The metallized pellets are finely ground on a ball mill, and the mass of the obtained metal particles with a particle diameter of ≤74 μm accounts for 90% of the total mass of the metal particles. Put the metal particles on a magnetic separator with a magnetic field strength of 1800Oe, the mass content of iron in the obtained recovered iron powder is 82%, and the recovery rate of metallic iron is 91%.

[0040] Add 5wt% CaO and 10wt% CaCl to recycled iron powder 2 As a flux a...

Embodiment 3

[0042] In this embodiment, oolitic high-phosphorus hematite is selected, the mass content of iron is 43.85%, and the content of phosphorus is 0.67 wt%. The oolitic high-phosphorus hematite was made into pellets and reduced under a reducing gas atmosphere at a temperature of 900°C. Among them, H 2 The volume of CO and CO accounted for 90% of the total volume of reducing gas, H 2 : CO = 2: 1, the reduction time is 4 hours, and the metallized pellets with a metallization rate of 90.20% are obtained.

[0043] The metallized pellets are finely ground on a ball mill, and the mass of the obtained metal particles with a particle diameter of ≤74 μm accounts for 86% of the total mass of the metal particles. Put the metal particles on a magnetic separator with a magnetic field strength of 1800Oe, the mass content of iron in the obtained recovered iron powder is 81%, and the recovery rate of metallic iron is 91%.

[0044] Add 3wt% CaO and 5wt% CaCl to recycled iron powder 2 As a flux ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com