A vc/a-c:h nanocomposite coating on the surface of a substrate and its preparation method

A nano-composite coating and composite coating technology, applied in the surface field, can solve the problems of unsuitable precision, substrate size change, and thick coating thickness, etc., and achieve simple and easy preparation methods, high hardness self-lubricating properties, The effect of good self-lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In the present embodiment, the substrate is GCr15 bearing steel, and the VC / a-C:H composite coating is prepared on the surface of the substrate, and the preparation method is as follows:

[0048] (1) Pre-plating treatment

[0049] Put the substrate in petroleum ether, and clean it with ultrasonic stirring for 15 minutes. After removing the oil on the surface of the substrate, put it into acetone and ultrasonically clean it for 15 minutes, then ultrasonically clean it in absolute ethanol for 15 minutes, and finally take it out and blow it dry with nitrogen.

[0050] (2) Bias reverse sputter cleaning

[0051] Put the substrate treated in step (1) into the multi-arc ion plating chamber, the temperature of the chamber is 350°C, and the back vacuum is pre-evacuated to 4.00×10 -3 Pa; then, pass Ar gas with a purity greater than or equal to 99.999% into the cavity, the Ar gas flow rate is 100 sccm, the substrate is applied with a negative bias voltage, and the substrate is co...

Embodiment 2

[0065] In the present embodiment, the matrix is exactly the same as that in Example 1, and the VC / a-C:H composite coating is prepared on the surface of the matrix, and the preparation method is as follows:

[0066] (1) is the same as step (1) in Example 1.

[0067] (2) is the same as step (2) in Example 1.

[0068] (3) is the same as step (3) in Example 1.

[0069] (4) Deposition of VC / a-C:H composite coating

[0070] Keep the Ar gas flow constant, and then pass C with a purity greater than or equal to 99.9% into the cavity 2 h 2 As a reactive gas, the flow rate is 100sccm, and the vacuum degree is maintained at 1.20Pa; the V target current is increased to 65A, the deposition temperature is maintained at 400°C, and a bias voltage of -150V is applied to the substrate to deposit VC / a-C:H composite coating on the substrate surface , deposition time 120min.

[0071] (5) is the same as step (5) in Example 1.

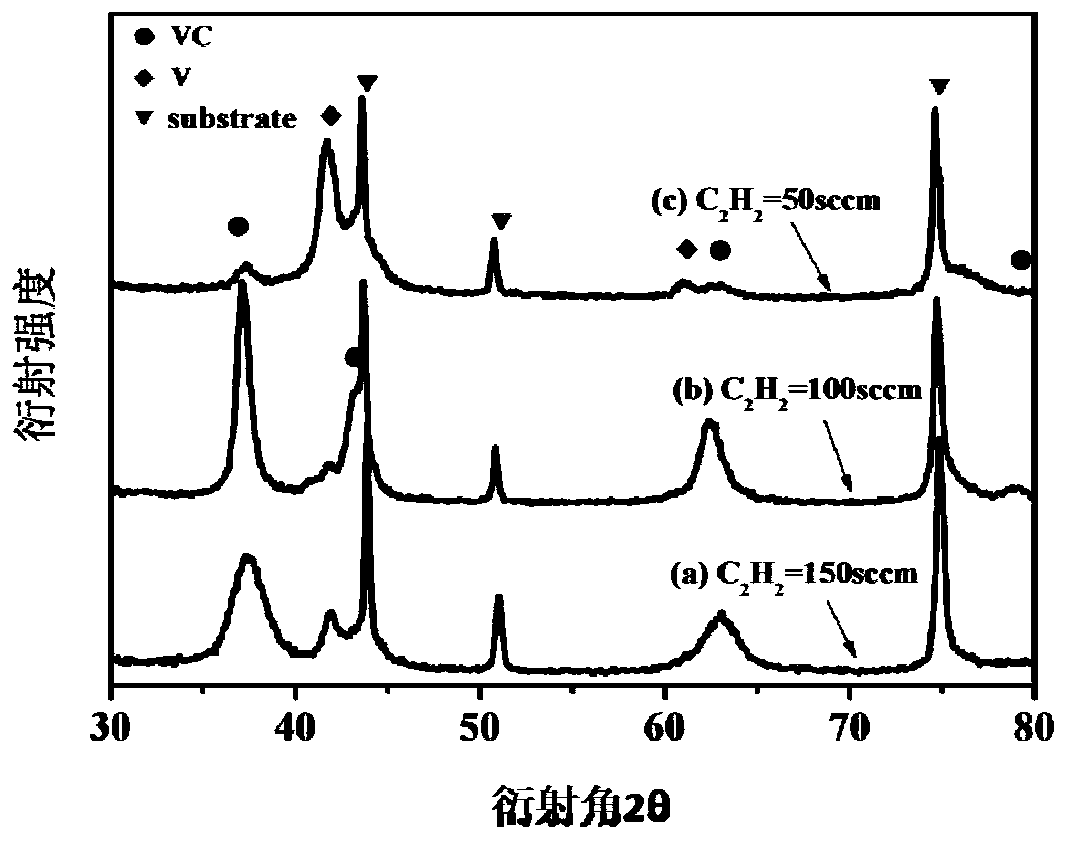

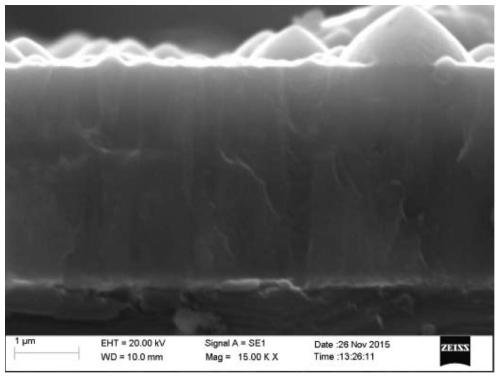

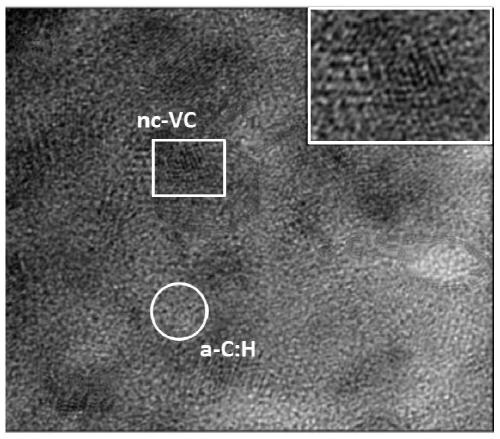

[0072] The cross-section SEM figure of the above-mentioned VC / a-...

Embodiment 3

[0080] In the present embodiment, the matrix is exactly the same as that in Example 1, and the VC / a-C:H composite coating is prepared on the surface of the matrix, and the preparation method is as follows:

[0081] (1) is the same as step (1) in Example 1.

[0082] (2) is the same as step (2) in Example 1.

[0083] (3) is the same as step (3) in Example 1.

[0084] (4) Deposition of VC / a-C:H composite coating

[0085] Keep the Ar gas flow constant, and then pass C with a purity greater than or equal to 99.9% into the cavity 2 h 2 As a reactive gas, the flow rate is 50sccm, and the vacuum degree is maintained at 1.0Pa; the V target current is increased to 65A, the deposition temperature is maintained at 400°C, and a bias voltage of -150V is applied to the substrate to deposit VC / a-C:H composite coating on the substrate surface , deposition time 120min.

[0086] (5) is the same as step (5) in Example 1.

[0087] The cross-section SEM figure of the above-mentioned VC / a-C:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com