Two-component polymer microfiber containing synthetic polypeptide and chitosan and its preparation

A technology of ultrafine fiber and chitosan, which is applied in the direction of fiber treatment, fiber chemical characteristics, cellulose/protein conjugated artificial filament, etc., can solve the problem of high cost, improve hydrophilicity, promote adhesion and growth in Proliferation and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of spinning dope

[0040] A mixed solvent was prepared by mixing trifluoroacetic acid and dichloromethane at a volume ratio of 7:3 (v:v). Dissolve poly(γ-benzyl L-glutamate) (molecular weight 220000g / mol) and chitosan (molecular weight 124000g / mol) in the above mixed solvent at a mass ratio of 8:2 (w:w) to prepare A solution with a polymer concentration of 2.0 wt%. The prepared solution was sealed and stirred at room temperature until uniform and transparent to obtain an electrospinning stock solution.

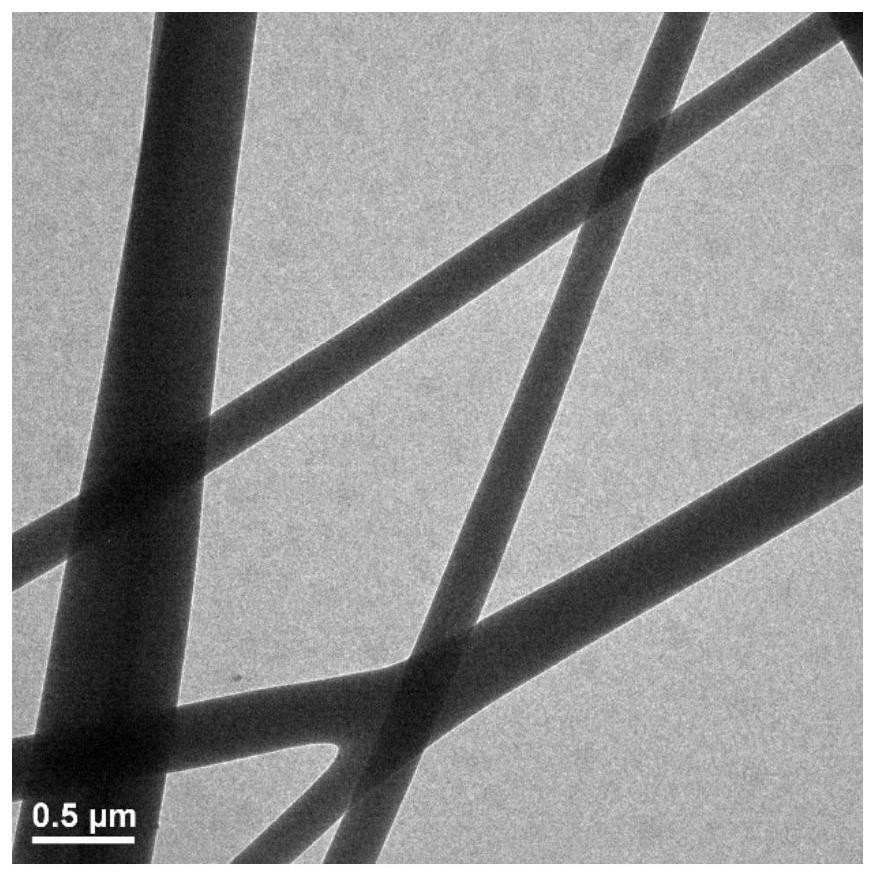

[0041] (2) High voltage electrospinning

[0042] The spinning dope prepared in step (1) was subjected to high-voltage electrospinning under the conditions of spinning voltage 20kV, flow rate 1.0mL / h, and receiving distance 10cm.

[0043] (3) Cross-linking

[0044] Using glutaraldehyde as a cross-linking agent, the chitosan component in the electrospun fiber prepared in step (2) was cross-linked for 12 hours by steam fumigation, and then vacuum-dried ...

Embodiment 2

[0048] The preparation steps are the same as in Example 1, except that the step (3) is not performed, that is, the ultrafine fibers obtained by electrospinning are not cross-linked.

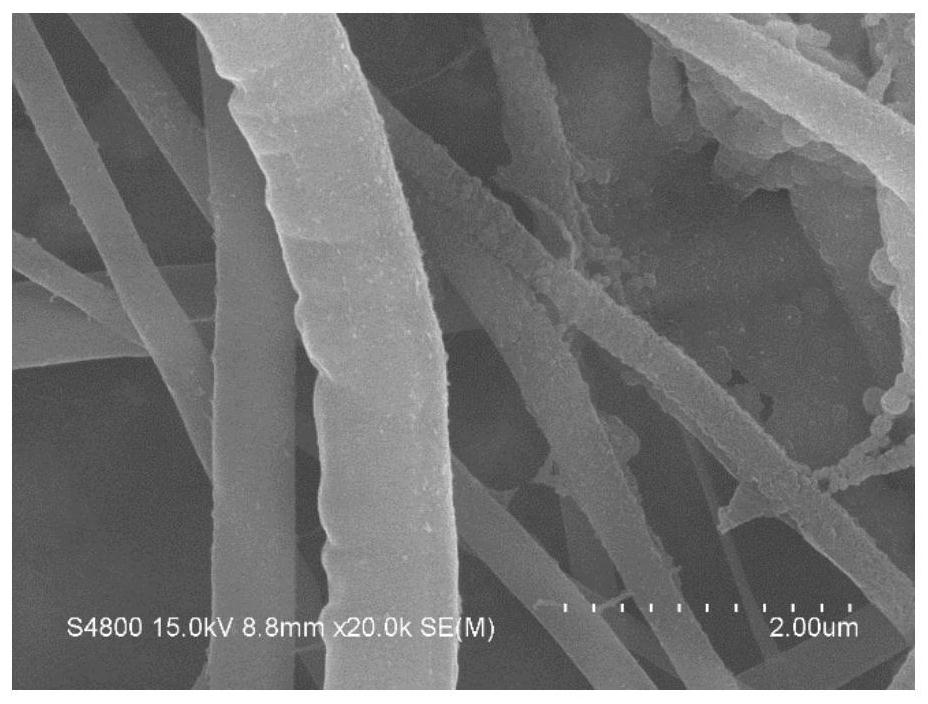

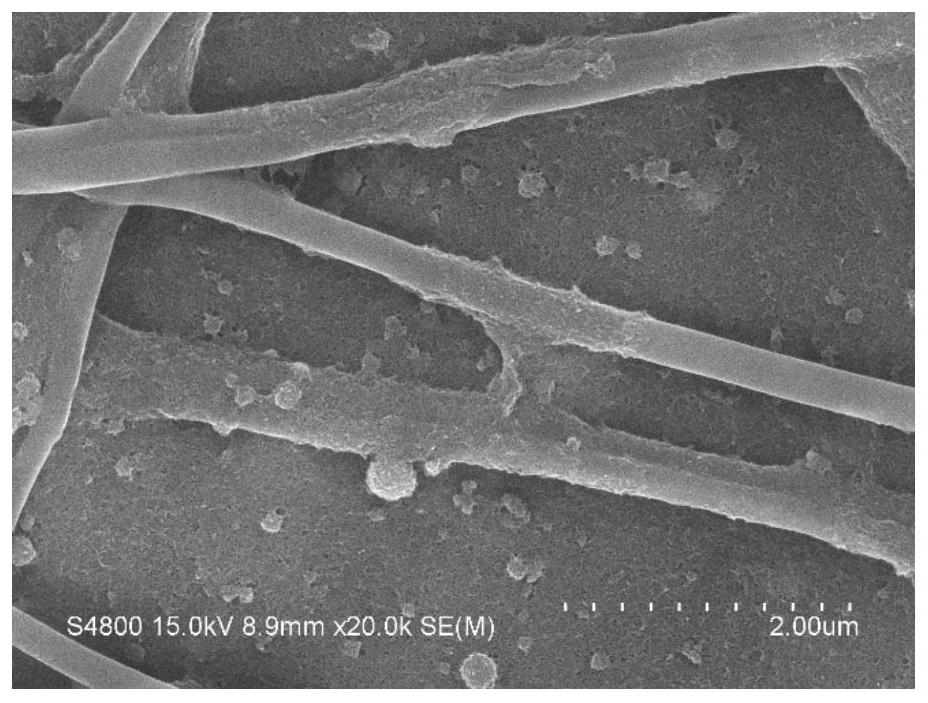

[0049] Fiber morphology was observed by scanning electron microscopy (see figure 2), the fibers were partially damaged after water immersion, indicating that the water resistance of uncrosslinked fibers was worse than that of crosslinked fibers. The cell affinity of fibers was tested by MTT assay (see Figure 4 ), compared with the blank reference, the cell survival rate was 127%, indicating that the prepared uncrosslinked two-component polymer ultrafine fiber cell affinity is weaker than the crosslinked fiber, but it can still significantly promote the growth and proliferation of cells.

Embodiment 3

[0051] (1) Preparation of spinning dope

[0052] Mix dichloroacetic acid and chloroform at a volume ratio of 6:4 (v:v) to prepare a mixed solvent. Dissolve poly(γ-benzyl L-glutamate) (molecular weight: 20,000 g / mol) and chitosan (molecular weight: 300,000 g / mol) in the above mixed solvent at a mass ratio of 9:1, and prepare a polymer concentration of 5.0 wt% solution. The prepared solution was sealed and stirred at room temperature until uniform and transparent to obtain an electrospinning stock solution.

[0053] (2) high voltage electrospinning (same as embodiment 1)

[0054] (3) Cross-linking

[0055] Carry out with reference to embodiment (1) step (3), difference is, the cross-linking agent that adopts is glyoxal.

[0056] (4) fiber performance test (with embodiment 1)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com