Upper spindle rod suspended rod flyer with bobbin hanging unloading mechanism

A bobbin and flyer technology, applied in textiles and papermaking, etc., can solve the problems of declining efficiency, inconsistency in saving resources, protecting the environment and low-carbon circular development, and achieving the effects of saving resources, improving labor productivity, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

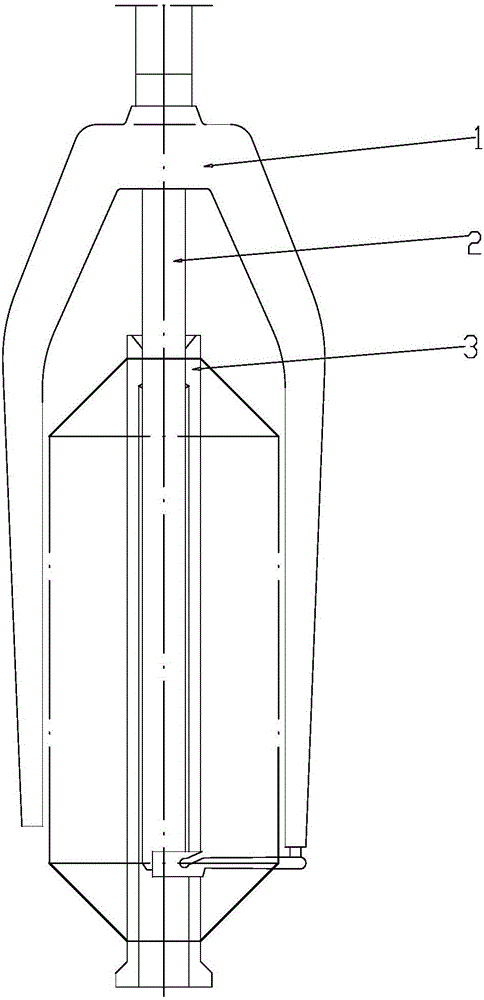

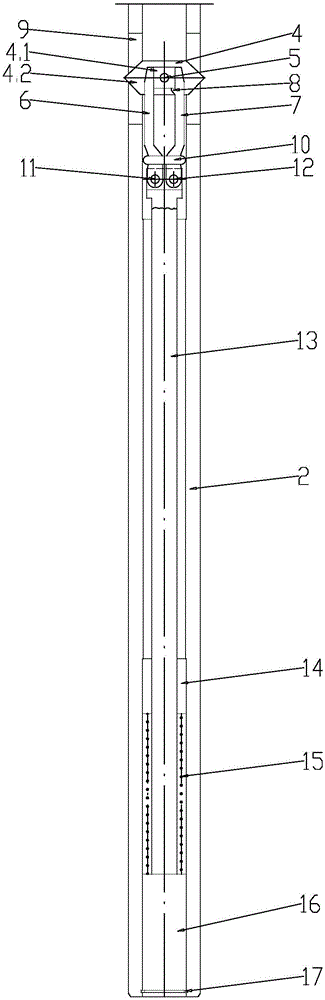

[0014] Such as Figure 1~2 As shown, the present invention mainly includes a flyer main body 1, a hollow spindle bar 2 and a hollow bobbin 3, the flyer main body 1 is sleeved on the hollow spindle bar 2, a hollow bobbin tube 3 is sleeved on the hollow spindle bar 2, and the hollow bobbin tube 3. It can perform relative rotational movement and up-and-down reciprocating movement along the hollow spindle bar 2.

[0015] The hollow spindle bar 2 is provided with a left and right through locking hole 9 , and the inner side wall of the hollow spindle bar 2 is connected to the hexagonal claw 4 through the horizontal pin 5 .

[0016] The hexagonal claw 4 includes a central fixed block 4.1 with a square structure, and two claw bodies 4.2 are symmetrically arranged on the left and right ends of the central fixed block 4.1.

[0017] The hexagonal claw 4 can rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com