Applied to multi-axial warp knitting equipment flattened carbon yarn twistless interlining system

A multi-axial, warp knitting technology, applied in warp knitting, textiles, papermaking, knitting, etc., can solve problems such as easy twisting, fluffing, and separation, and achieve the effect of avoiding friction and breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

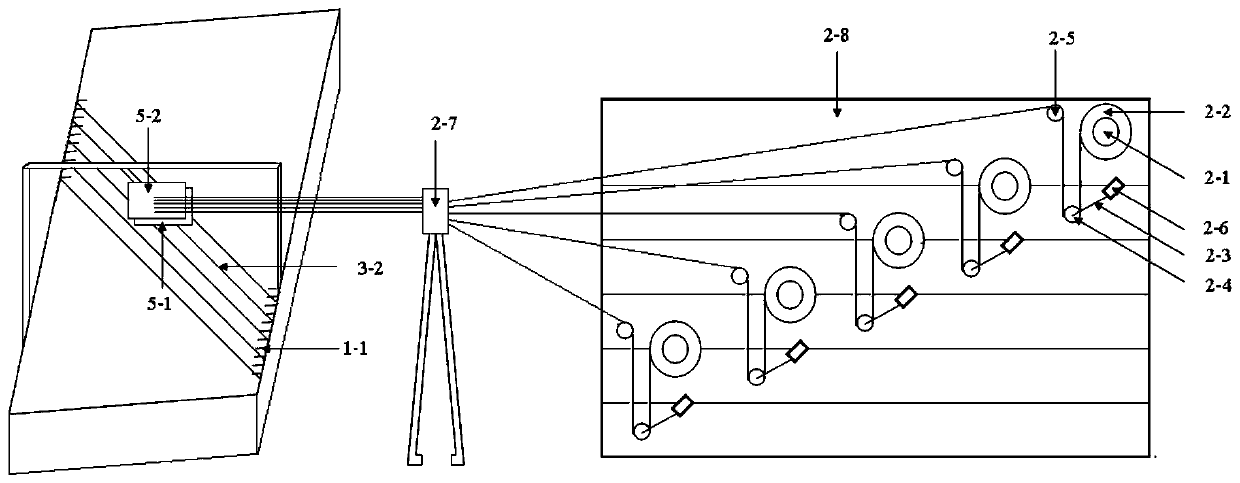

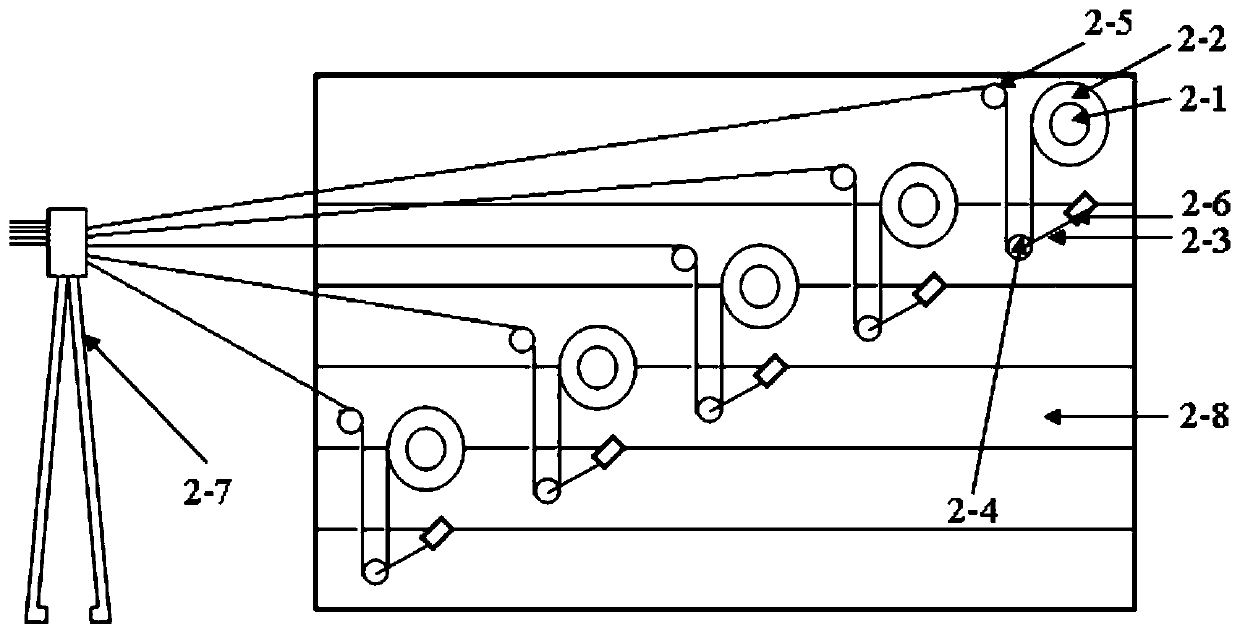

[0037] This embodiment provides a flattened carbon yarn interlining system applied to multiaxial warp knitting equipment, including a yarn unwinding device and a weft insertion device, and the weft insertion device is arranged at the front end of the yarn unwinding device; wherein:

[0038] The unwinding device is used to unwind and unwind the flattened yarn in the creel and output it to the weft insertion device; the unwinding refers to horizontally unfolding in the same plane of the flattened yarn along the width direction;

[0039] The weft insertion device is used to complete the weft insertion process.

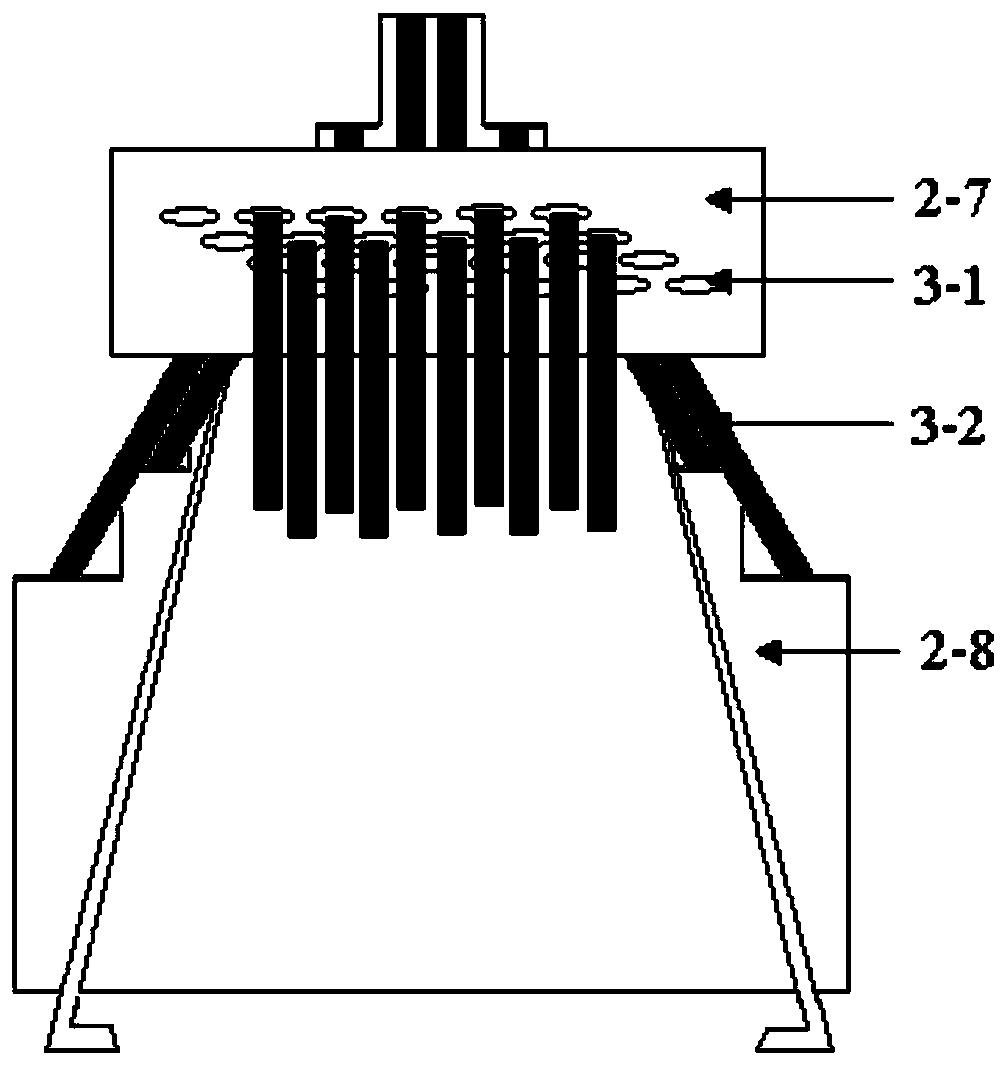

[0040] Further, the yarn unwinding device includes a convex stepped creel and a wire collecting frame, and the silk collecting frame is arranged between the convex stepped creel and the weft insertion device.

[0041] Further, the convex stepped creel includes a convex stepped mounting frame and at least one set of unwinding device and tensioning device mounted on the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com