Preparing method of terylene blended fabric dyeing solution

A blended fabric and dyeing solution technology, which is applied in dyeing, textiles and papermaking, can solve the problems of polyester blended fabrics such as difficulty in coloring, poor level dyeing, and low color fastness, so as to avoid deterioration of dyeing effect and improve softness Sex, the effect of lowering the dyeing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

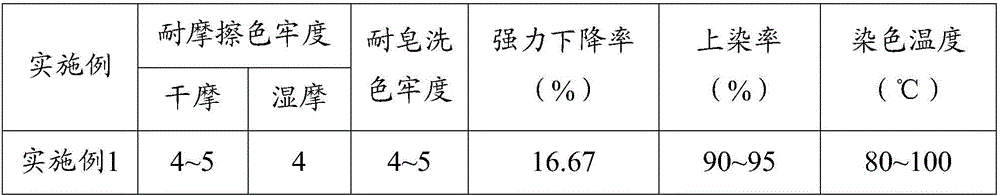

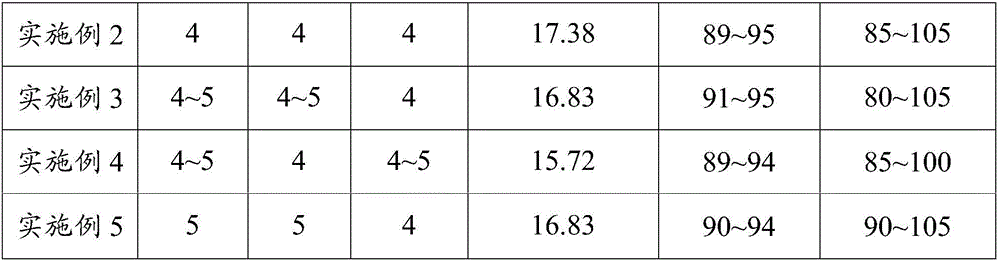

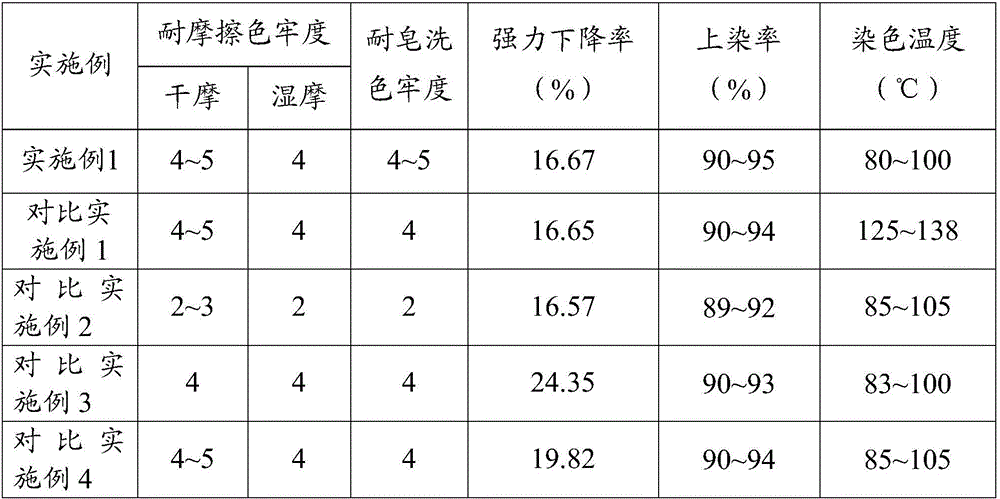

Examples

preparation example Construction

[0028] The invention provides a method for preparing a polyester blended fabric dyeing liquid, comprising the following steps:

[0029] (1) Add deionized water to the mixed powder of cobalt sulfate, aluminum sulfate, ferrous sulfate and sodium sulfate, keep the temperature at 30-55°C, and stir for 0.5-1.5 hours;

[0030] (2) In the material obtained in step (1), first add glycerin and glycerol and mix evenly, then add diphenyl ether tetra-acid dianhydride, fatty alcohol polyoxyethylene ether, trimethylolpropane, acetanilide and ethyl alcohol Sodium diaminetetraacetic acid, maintain the temperature at 40-65°C, and treat for 1.5-4 hours;

[0031] (3) Add catalyst, modifying agent, diffusing agent and surfactant to the material obtained in step (2), maintain the temperature at 25-40° C., and ultrasonically react for 0.5-2 hours.

[0032] Preferably,

[0033] In the step (1), maintain the temperature at 35-45°C and stir for 0.5-1h;

[0034] In the step (2), the temperature is m...

Embodiment 1

[0042] The polyester blended fabric used in this embodiment of the present invention is a blended fabric of polyester and wool, wherein the weight ratio of polyester is 60%, and the medicines used are all calculated in parts by weight.

[0043] A kind of polyester blend fabric dyeing liquid preparation method of the present invention comprises the following steps:

[0044] (1) Take 0.5 parts of cobalt sulfate, 1 part of ferrous sulfate, 0.5 parts of sodium sulfate, add 10 parts of deionized water, and stir for 0.5 hours at a temperature of 35 °C;

[0045] (2) In the material obtained in step (1), first add 3 parts of glycerin and mix evenly, then add 3 parts of diphenyl ether tetra-acid dianhydride, 2 parts of fatty alcohol polyoxyethylene ether, 3 parts of trimethylolpropane, 4 parts of acetanilide, 2 parts of di-sodium edetate, maintain the temperature at 45°C, and treat for 2 hours;

[0046] (3) Add 1 part of transglutaminase to the material obtained in step (2), 2 parts o...

Embodiment 2

[0048] The polyester blended fabric used in this embodiment of the present invention is a blended fabric of polyester, wool and acetate fiber, wherein the weight ratio of polyester is 65%, and the medicines used are all calculated by parts by weight.

[0049] A kind of polyester blend fabric dyeing liquid preparation method of the present invention comprises the following steps:

[0050] (1) Take 1 part of cobalt sulfate, 1.5 parts of ferrous sulfate, 0.8 parts of sodium sulfate, add 10 parts of deionized water, and stir for 1 hour at a temperature of 38°C;

[0051] (2) In the material obtained in step (1), first add 4 parts of glycerin and mix evenly, then add 4 parts of diphenyl ether tetra-acid dianhydride, 3 parts of fatty alcohol polyoxyethylene ether, 4 parts of trimethylolpropane, 3 parts of acetanilide, 4 parts of di-sodium edetate, maintain the temperature at 50°C, and treat for 2.5h;

[0052] (3) Add 2 parts of transglutaminase to the material obtained in step (2), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com