Method for reinforcing connection of diaphragm plate and girder by aid of penetrating type prestress

A diaphragm and prestressing technology, applied to bridges, bridge materials, bridge maintenance, etc., to achieve the effects of strengthening horizontal connections, improving crack resistance, and improving overall mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

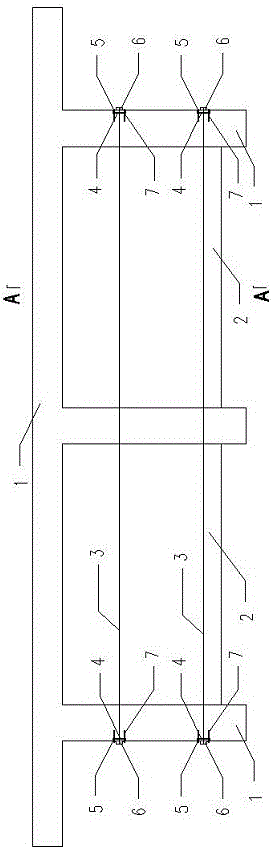

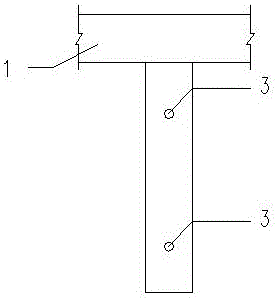

[0025] The present invention will combine below Figure 1-4 For further description:

[0026] a. First, determine the additional location of the prestressed steel strand 3 on the main girder 1 and the diaphragm 2. The bottom one is located at 1 / 5 of the beam height, and the top one is located at 7 / 10 of the beam height.

[0027] b. After the position of the prestressed steel strand 3 is determined, start drilling on the main girder 1 and the diaphragm 2 to form an installation channel for the prestressed steel strand 3. The diameter of the channel meets the requirement that the prestressed steel strand 3 pass through smoothly Can.

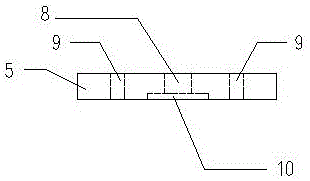

[0028] c. Process the stress diffusion steel backing plate 5, the steel plate is Q345 steel plate, the structural size is: length 20cm, width 20cm, thickness 2cm. Simultaneously, the groove of the prestressed anchorage 6 is machined at the central position on the stress diffusion steel backing plate 5, the depth of the groove is about 5mm, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com