Mass concrete cooling device based on air cooling, construction method and application

A large-volume concrete and cooling device technology, applied in infrastructure engineering, construction, etc., can solve problems such as strong dependence on water resources, waste, and high requirements for pipeline sealing, and achieve low dependence on water resources, simple operation, and geographical location The effect of small constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

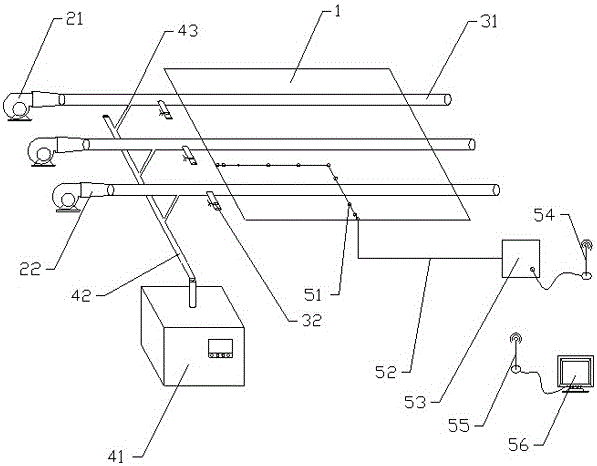

Image

Examples

Embodiment 1

[0031] A bridge approach bridge cap

[0032] 1) Project overview

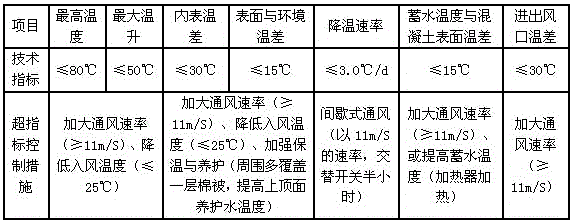

[0033] The main bridge of a certain bridge has a total length of 848m and is a seven-span, double-tower and double-cable-plane symmetrical mixed-girder cable-stayed bridge. The bridge has 8 auxiliary transition pier caps. All the caps are made of C40 marine concrete, and the caps of the auxiliary transition piers are poured and formed at one time.

[0034] 2) Construction status

[0035] The auxiliary transitional pier cap adopts the construction technology of wind-cooled mass concrete, and the one-time pouring construction was completed from late May to early June 2016. The ambient temperature on site is 25°C to 35°C. The construction on site is in good condition. Long-term observation shows that there is no crack in the concrete, and the temperature field has been scientifically and effectively analyzed, and the entire construction process has achieved the expected effect. Its successful temperature contr...

Embodiment 2

[0048] A bridge main line abutment

[0049] 1) Project overview

[0050] The main span of a certain bridge is a single-span simply supported steel box girder suspension bridge, and approach bridges are set on both banks, with a total length of 2030m. The construction of the present invention relies on the abutment, which is the connecting part of the bridge and road, and has a large volume, and is formed by one-time pouring of C35 concrete.

[0051] 2) Construction status

[0052] The abutment adopts wind-cooled mass concrete construction technology, and the construction was completed from the end of November to mid-December 2015. The ambient temperature is about 8°C to 15°C. The site construction is in good condition and there are no cracks, which has been agreed by the owner and the supervisor. praise.

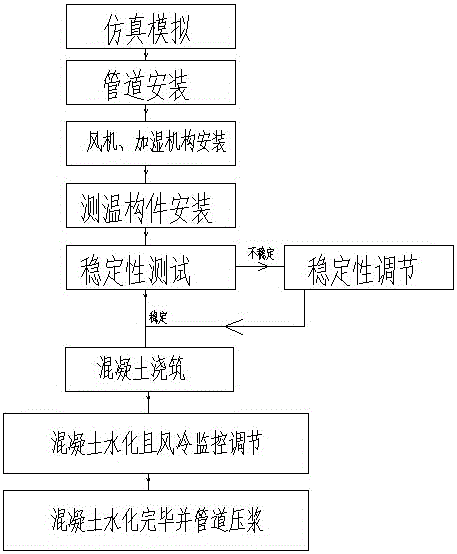

[0053] 3) The specific construction method is as follows:

[0054] ① First, simulate the pipeline layout and overall stress of the building to be constructed, and determ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com