Integrated wallboard with heat retaining and decorative structure made of wasted red bricks and preparation method thereof

A technology of structural insulation and red bricks, which is applied in building components, building structures, buildings, etc., can solve the problem that red brick waste cannot be reused, achieve good feasibility and industrialization prospects, light weight, sound insulation and heat preservation effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

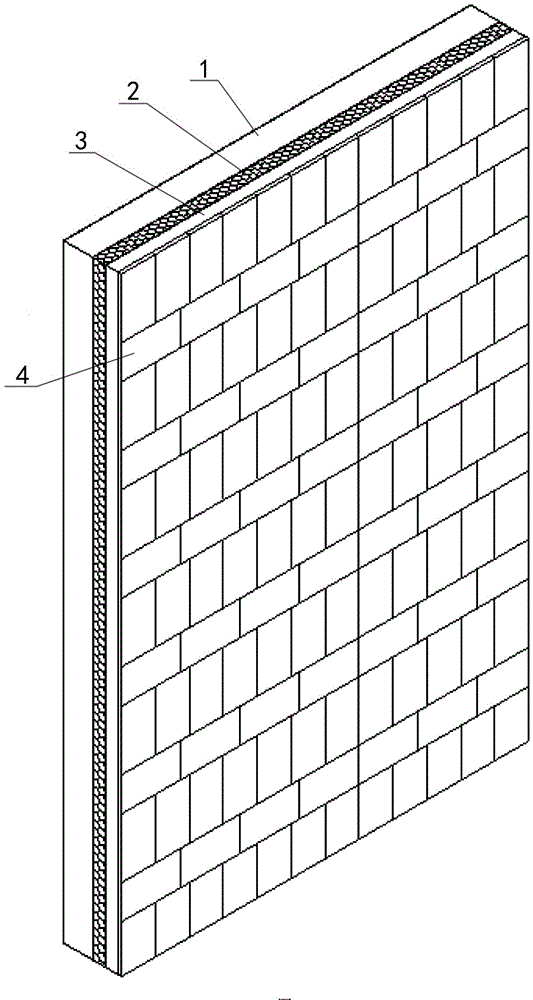

[0051] The integrated wall panel for thermal insulation and decoration using the waste red brick structure includes:

[0052] A recycled aggregate structure layer 1 with a thickness of 80mm, a polystyrene board with a thickness of 40mm as an insulation layer 2, a mortar protection layer 3 with a thickness of 50mm, and a decorative layer 4 of discarded red bricks with a thickness of 10mm.

[0053] The parts by weight of each component of the above-mentioned recycled aggregate structure layer are as follows:

[0054] 1.65 parts of waste red brick coarse aggregate;

[0055] Waste red brick fine aggregate 0.95 parts;

[0056] 1 part of cement;

[0057] 0.38 parts of water.

[0058] The waste red brick fine aggregate is composed of waste red brick powder and tailings sand, and the mixing weight ratio of the two is 1:2.

[0059] Embodiment 1 The production method of this kind of integrated wall panel using waste red brick structure heat preservation and decoration, the productio...

Embodiment 2

[0072] The integrated wall panel for thermal insulation and decoration using the waste red brick structure includes:

[0073] A recycled aggregate structure layer 1 with a thickness of 120mm, a polystyrene board with a thickness of 60mm as an insulation layer 2, a mortar protection layer 3 with a thickness of 50mm, and a decorative layer 4 of discarded red bricks with a thickness of 20mm.

[0074] The parts by weight of each component of the above-mentioned recycled aggregate structure layer are as follows:

[0075] 2.05 parts of waste red brick coarse aggregate;

[0076] 1.05 parts of waste red brick fine aggregate;

[0077] 1 part of cement;

[0078] 0.4 parts of water.

[0079] The waste red brick fine aggregate is composed of waste red brick powder and tailings sand, and the mixing weight ratio of the two is 1:3.

[0080] Embodiment 2 The method of making the integrated wallboard for thermal insulation and decoration using the waste red brick structure is the same as t...

Embodiment 3

[0082] The integrated wall panel for thermal insulation and decoration using the waste red brick structure includes:

[0083] Recycled aggregate structure layer 1 with a thickness of 100mm, polystyrene board with a thickness of 50mm as insulation layer 2, mortar protection layer 3 with a thickness of 50mm, and decorative layer 4 of discarded red bricks with a thickness of 10mm.

[0084] The parts by weight of each component of the above-mentioned recycled aggregate structure layer are as follows:

[0085] 2.55 parts of waste red brick coarse aggregate;

[0086] 1.55 parts of waste red brick fine aggregate;

[0087] 1 part of cement;

[0088] 0.45 parts of water.

[0089] The waste red brick fine aggregate is composed of waste red brick powder and tailings sand, and the mixing weight ratio of the two is 1:2.5.

[0090] Embodiment 3 The method of making the integrated wallboard for thermal insulation and decoration using the waste red brick structure is the same as that of E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com