Octagonal circular-section solid steel pipe concrete component and manufacturing method thereof

A technology of steel pipe concrete and its manufacturing method, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problem that the confinement effect of core concrete is not as good as it is, and achieve the effect of improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

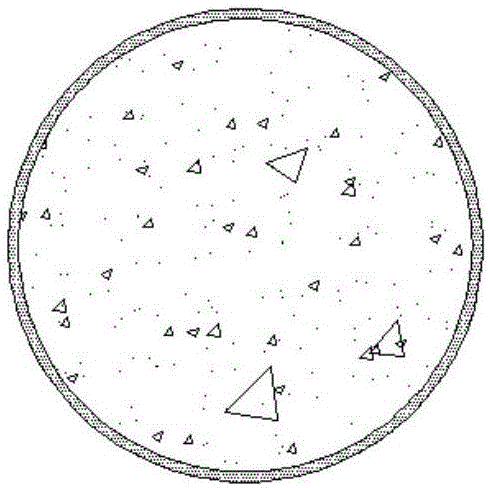

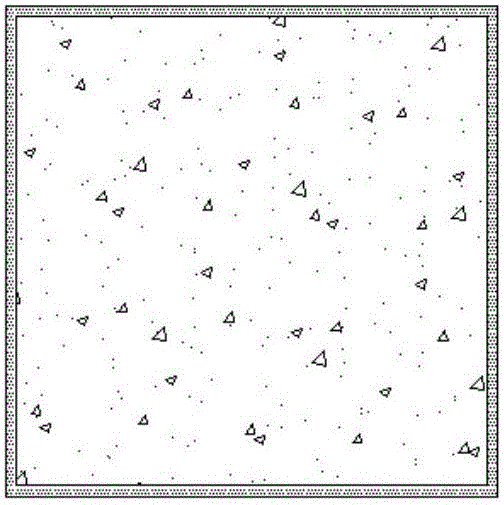

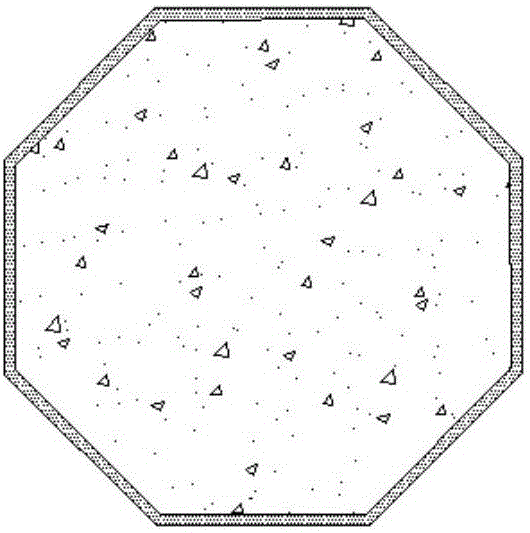

[0031] refer to Figure 4 and Figure 5 , discloses a solid steel pipe concrete member with octagonal circular section, comprising steel pipe 1 and concrete 2, the outer edge of the cross section of the steel pipe 1 is octagonal, the inner edge is circular, and the diameter of the cross section of the concrete column 2 is 165mm, the column height is 500mm, the concrete is made of ordinary Portland cement and standard coarse and fine aggregate according to the construction mix ratio, and the strength grade is C40. In other embodiments, it may be high-performance concrete with self-compacting properties whose strength grade is not lower than C30, and the maximum particle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com